Antibacterial jacket and production process thereof

A technology of coat and antibacterial finishing solution, which is applied in the field of textiles, can solve the problems of antibacterial coat antibacterial effect decline, ofloxacin shedding, etc., and achieve the effects of improving the fixing effect, reducing oxidation damage, and promoting molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation example of antibacterial capsule

[0043] The raw materials used in the preparation examples of this application can all be obtained from the market, wherein ofloxacin is provided by Puluo Pharmaceutical Co., Ltd., deionized water is provided by Jinan Xinyuancheng Chemical Technology Co., Ltd., and gelatin is selected from Shandong Huanlai The industrial gelatin provided by Chemical Co., Ltd., the zeolite powder is selected from the 1250 mesh zeolite powder provided by Lingshou County Demao Mineral Products Processing Co., Ltd., and the diatomite is selected from the 1250 mesh ultrafine diatomite provided by Lingshou County Shuncheng Mineral Products Processing Factory .

preparation example 1

[0046] The antibacterial capsule in this preparation example is prepared according to the following process:

[0047] (1) 24kg ofloxacin and 264kg deionized water are mixed uniformly to obtain the ofloxacin dispersion;

[0048] (2) Heat the fluoxacin dispersion to 55°C, then add 40kg of gelatin and 80kg of adsorbent to the fluoxacin dispersion, stir until the gelatin is dissolved, and obtain the capsule precursor liquid, wherein the adsorbent is selected from zeolite powder;

[0049] (3) Freeze-drying the capsule precursor liquid at -40° C., and then pulverizing the obtained dried product to an average particle diameter of 150 μm to obtain antibacterial capsules.

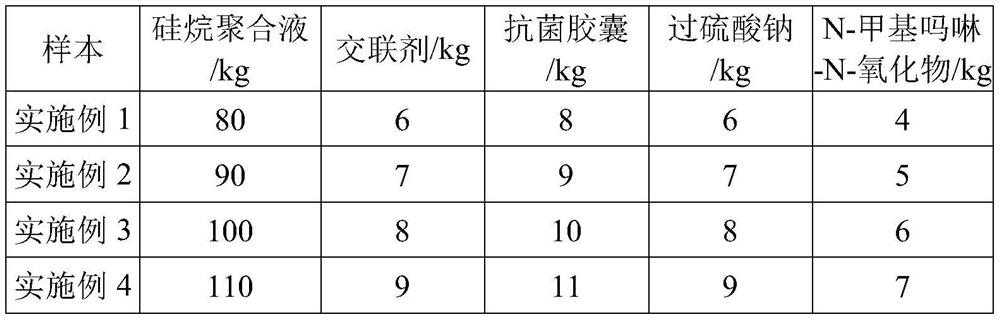

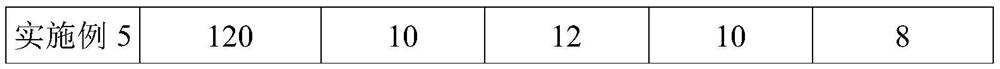

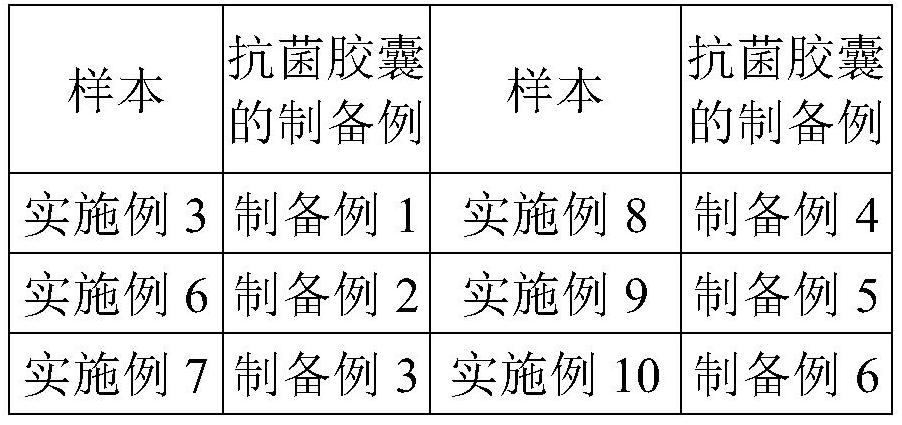

[0050] As shown in Table 1, the difference between Preparation Examples 1-5 is that the raw material proportions of the antibacterial capsules are different.

[0051] Table 1

[0052] sample Fluoxacin / kg Gelatin / kg Zeolite powder / kg Preparation Example 1 24 40 80 Preparation example 2 ...

preparation example 6

[0054] The difference between this preparation example and preparation example 3 is that the zeolite powder in preparation example 3 is replaced by diatomite of the same weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com