Maintenance system for high-energy water recovery of supercritical unit

A supercritical unit and water recovery technology, which is applied in separation methods, heating systems, chemical instruments and methods, etc., can solve the problems of strict chemical index requirements, difficult maintenance of high-energy water systems, and uncertain maintenance time of high-energy water recovery systems, etc. problem, to achieve the effect of simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

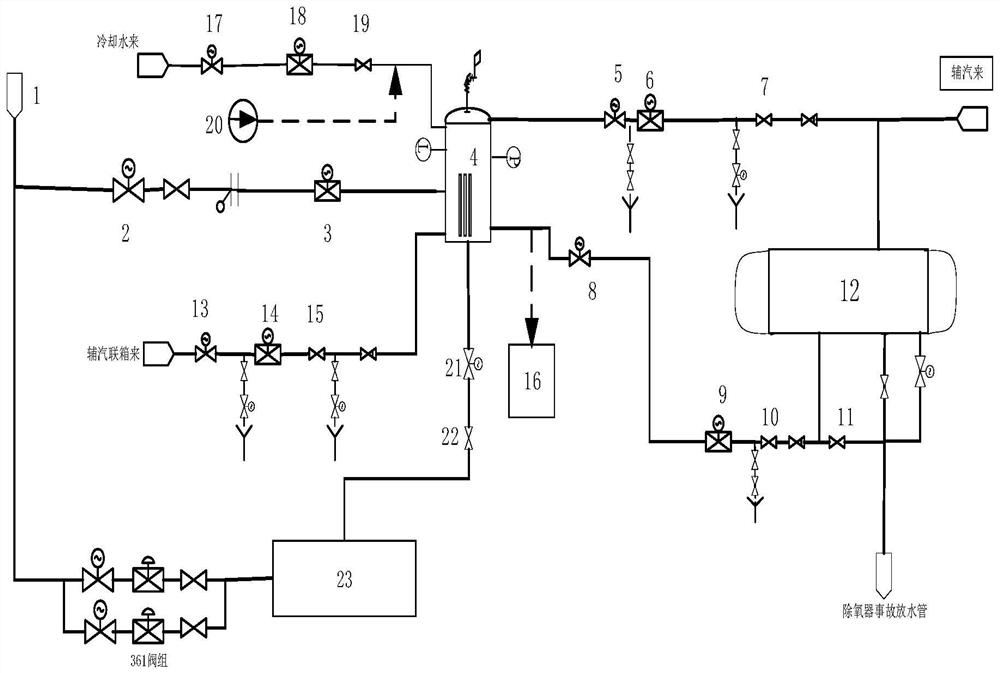

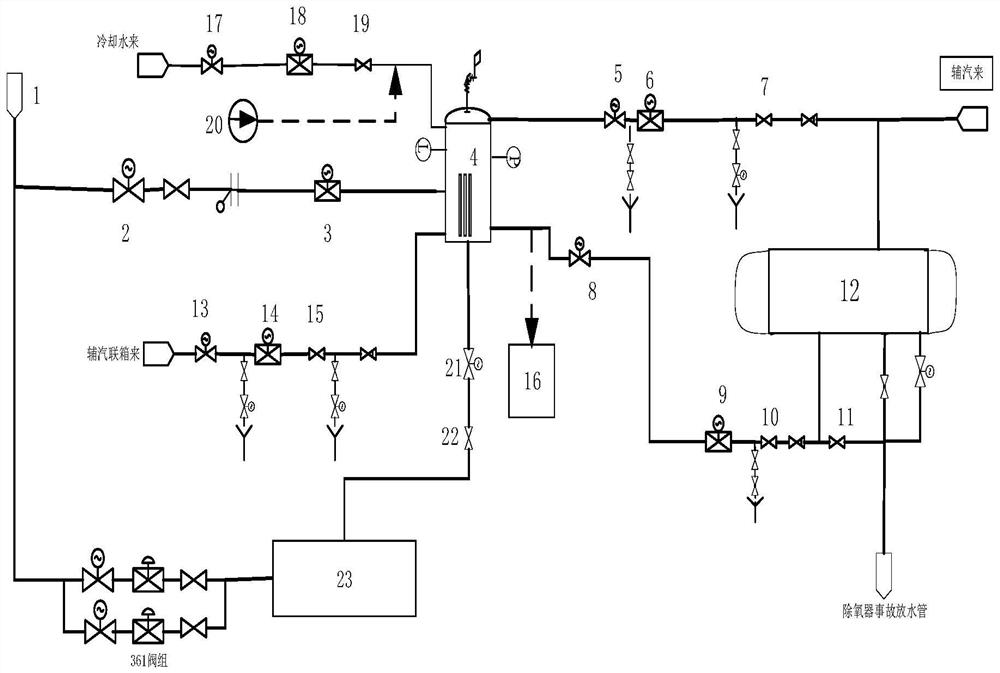

[0034] The following is an example of a high-energy water recovery system set up by a 350MW supercritical unit (main steam pressure 24MPa, main steam temperature 566°C). The expansion volume of the high-energy water recovery system is 10m 3 , The design rated recovery of high-energy water is 100t / h. After the high-energy water is expanded through the expansion vessel, the steam and water are recovered to the deaerator respectively. The present invention is described in further detail in conjunction with the accompanying drawings.

[0035] refer to figure 1 , a maintenance system for recovering high-energy water of a supercritical unit, comprising: boiler start-up separator water storage tank 1, boiler start-up separator water storage tank 1, boiler start-up separator water storage tank 1 through high-energy water electric isolation valve 2, high-energy water inlet water The flow regulating valve 3 is connected with the high-energy water expansion vessel 4, and the saturated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com