A device and method for purifying liquid argon

A liquid argon and purification tower technology, which is applied in the field of gas separation, can solve the problems of limited economic benefits, low purity of liquid argon, and inability to meet the requirements, and achieve the effects of improving economic benefits, wide application range, and small impact of changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

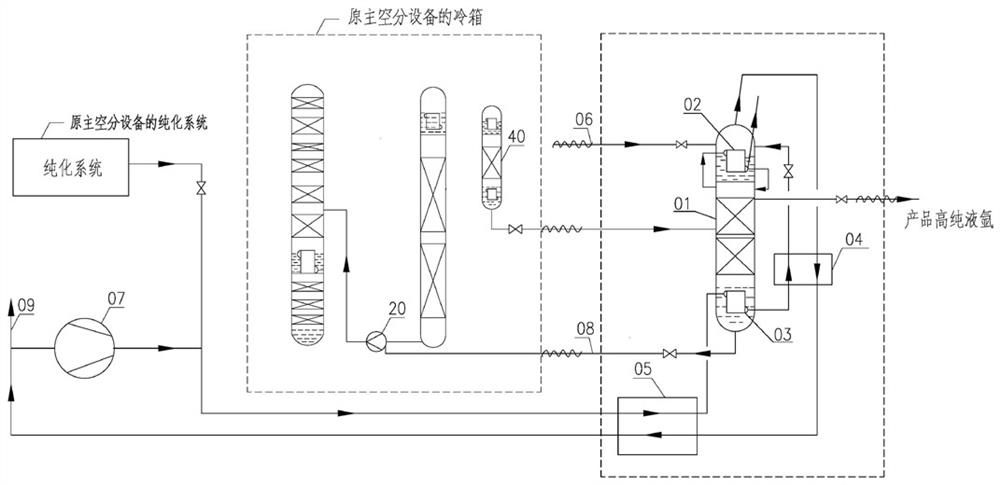

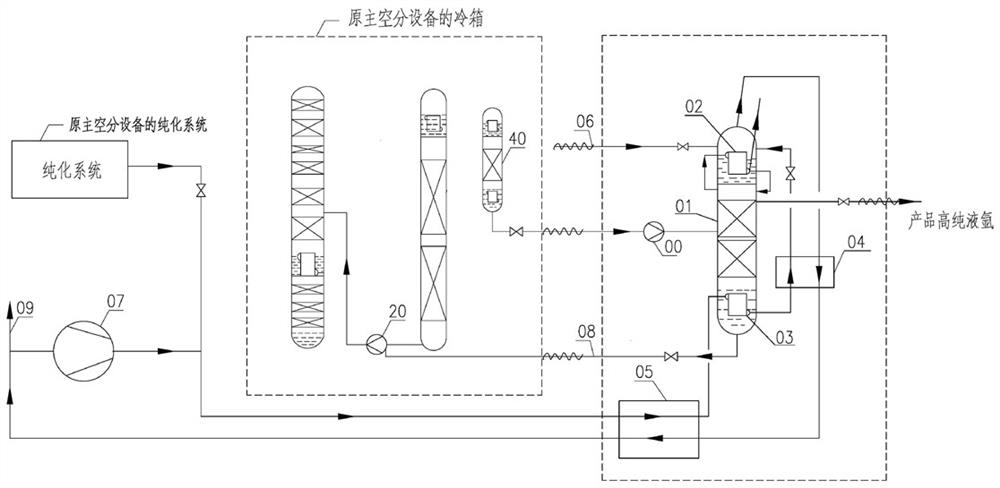

[0034] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown: the liquid argon with a purity of about 3 ppm oxygen and 4 ppm nitrogen from the bottom of the refining argon tower 40 of the original main air separation equipment enters the middle part of the liquid argon purification tower 01 through the input end of the raw material liquid in the middle part of the liquid argon purification tower 01 for rectification , In the middle and upper part of the liquid argon purification tower 01, a high-purity liquid argon product with an oxygen content of less than 0.2ppm, a nitrogen content of less than 0.5ppm, and each of hydrogen, carbon monoxide, carbon dioxide and total hydrocarbons (calculated as methane) less than 0.1ppm is obtained. Among them, the liquid argon purification tower 01 is a structured packing tower.

[0035] The clean and dry air compressed by the gas compressor 07 to about 0.35MPaA enters the heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com