Mineral insulation electric heating system for electric heating aided production of steam injection oil well

A technology of mineral insulation and steam injection, which is applied to ohmic resistance heating parts, electric heating devices, and the shape of heating elements, which can solve the problems of long heating cable length, discounted effect, and low operating temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

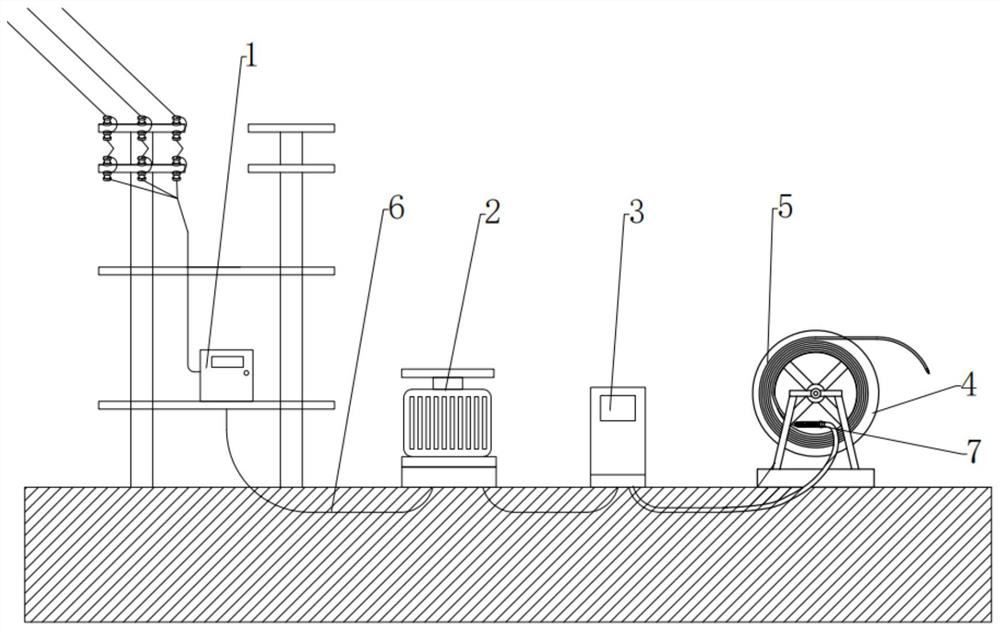

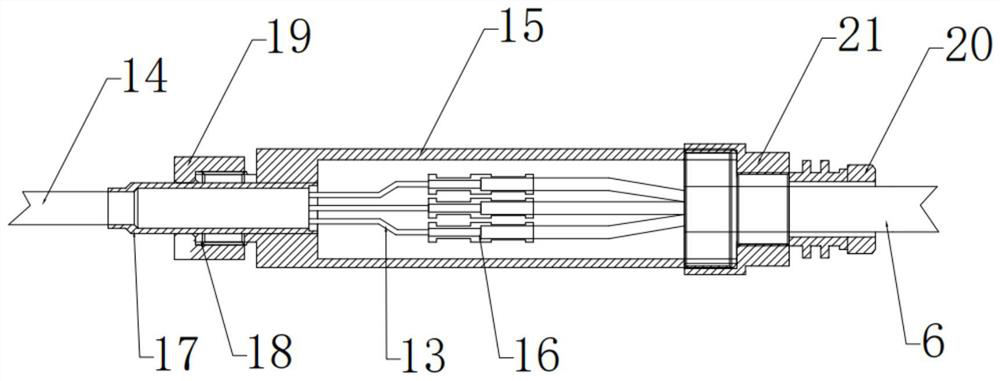

[0026] Example 1, such as Figure 1-4 As shown, the mineral insulated electric heating system for steam injection oil well electric heating auxiliary production includes 10kv power supply 1, step-down transformer 2, power regulating cabinet 3, cable turntable 4, heating element 5, power cable 6 and Christmas tree, the power cable 6 Turn on the 10kv power supply 1, step-down transformer 2 and power regulating cabinet 3, the heating element 5 is wound on the cable turntable 4, the head end of the heating element 5 is connected with a wiring assembly 7, and the tail end can be extended to oil production In the shaft of the tree, the power cable 6 is connected to the heating element 5 through the wiring assembly 7 .

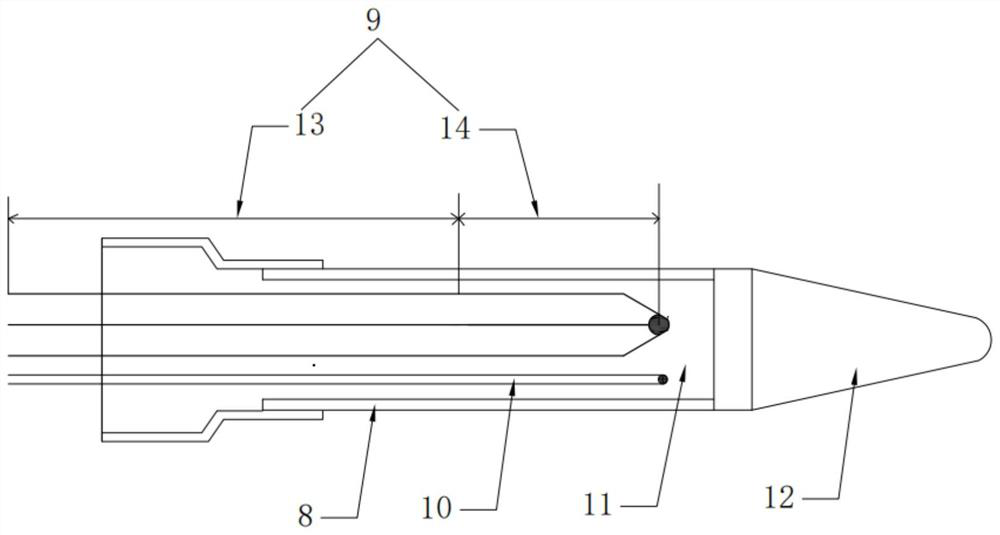

[0027] Specifically, the heating element 5 is a five-core integrated mineral insulated heating cable, which includes a metal outer sheath 8, three integrated cables 9, two thermocouple wires 10, insulating filler 11 and a tapered guide 12 , the integrated cable 9 ha...

Embodiment 2

[0036] Example 2: Scheme: total length 900m (after the first downhole 677m, see appendix 1 for the dimensions of the remaining cable reels)

[0037] ①The total length of the auxiliary pipe: 900m; the minimum inner diameter of the auxiliary pipe: 50mm

[0038]②Total cable length: 900+15=915m Outer sheath material SUS317L

[0039] ③ Cooling section outside the well: 15m; Cooling section inside the well: 700m (working temperature 270°C); hot section: 200m (working temperature 270°C)

[0040] ④Voltage: 1140 / 660VAC Voltage drop: 161V Current: 201A

[0041] Hot part power: 300kw; cold part power: 97.7kw; total installed power: 397.7kw

[0042] ⑤T2 cold wire: 6.2m in diameter; NC020 hot wire: 4.8mm in diameter; even wire: 2mm in diameter

[0043] 20℃ cold core resistance: 0.4Ω; 270℃ cold core resistance: 0.8Ω

[0044] 20℃ heating wire core resistance: 2.232Ω; 270℃ heating wire core resistance: 2.465Ω

[0045] ⑥ In-well cold wire under steam environment: 139W / m; In-well hot wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com