Alkaline electrolyte regeneration

An electrolytic regeneration, electrolyte technology, applied in the direction of alkaline electrolyte, aqueous electrolyte, electrolytic components, etc., can solve problems such as reducing the efficiency of metal-air power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

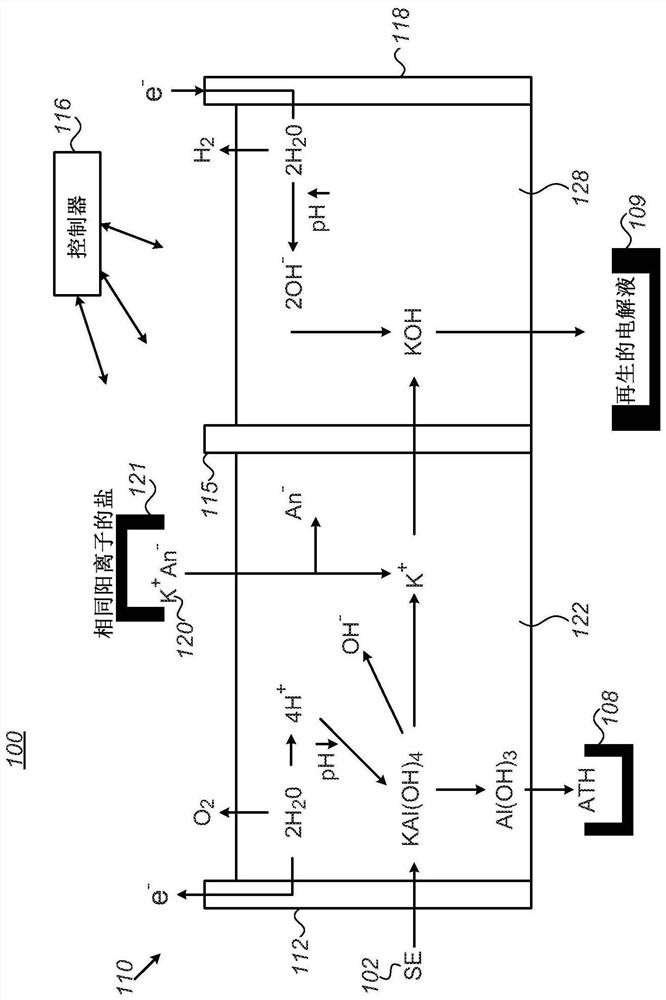

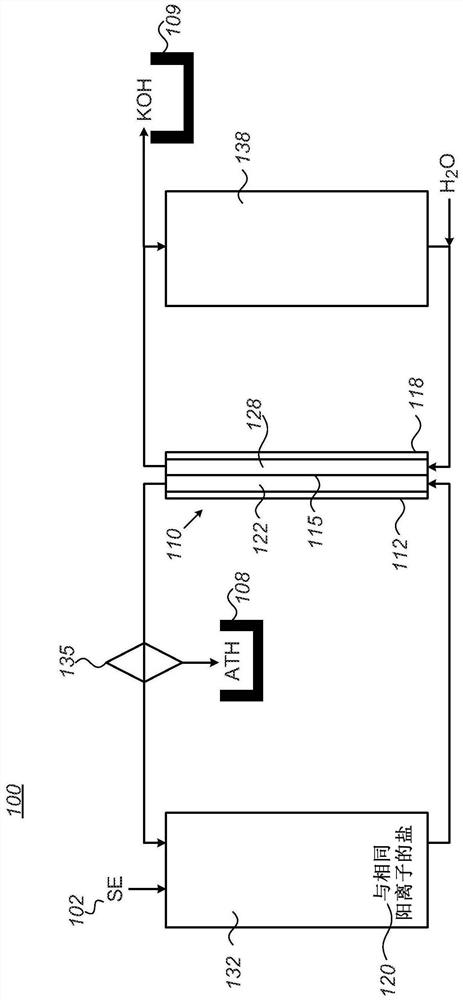

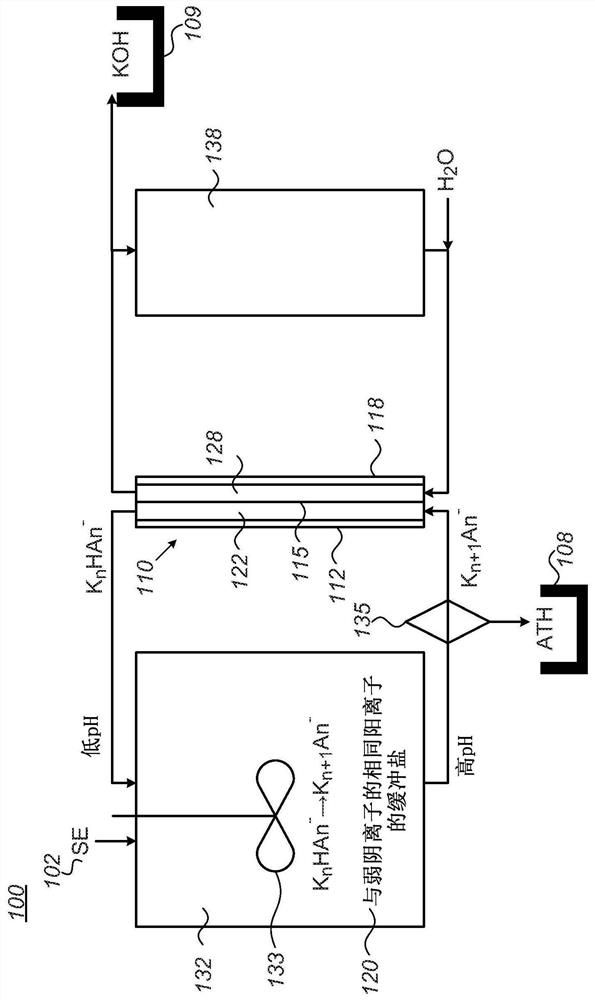

Method used

Image

Examples

Embodiment

[0069] In the following, non-limiting examples for the preparation and operation of system 100 and method 200 are provided. These examples illustrate the applicability of the disclosed method 200 and system 100 and do not limit the scope of the invention.

[0070] Example 1 - System Settings

[0071] The system consists of two chambers (made of PMMA, one for the anolyte and one for the catholyte, 2.5 L each. The dimensions of each tank are 10 x 10 x 16 cm and a membrane separates the two chambers ). A peristaltic pump (Hontile Industrial Co.LTD) circulated the electrolyte through the electrolytic membrane tank. The electrolyzer was connected to a power source (Mancon Hcs3042) where the voltage / current was recorded by a computer and the pH of the anolyte compartment was also continuously monitored.

[0072] A separate beaker containing 100 mL of filtered spent electrolyte (SE) was placed adjacent to the anolyte compartment. The composition of the spent electrolyte is as fol...

Embodiment 2

[0075] Embodiment 2-electrolytic membrane tank device

[0076] 99.6% pure nickel plate is used as the anode and the cathode is made by Phinergy TM Production of air cathodes. The membrane is a commercially available N551WX K + Nafion membrane. Zinc wires wrapped in Teflon sleeves were placed adjacent to both sides of the membrane. The anode and cathode potentials (vs. Zn / ZnO) were continuously recorded.

Embodiment 3

[0077] Example 3 - Parameters and Experimental Conditions Examined I

[0078] Electrolyzer at room temperature 100mA / cm 2 (normalized to membrane surface area) was run at constant current. Before adding SE, the pH of the anolyte was first adjusted to a lower value (−10.5). The addition of SE was manually adjusted to maintain the pH at 9-10.5.

[0079] The parameters evaluated in this experiment were: the potential of the anode and cathode (relative to the reference electrode); the iR drop caused by the membrane (and solution resistance); the corrosion current efficiency (CCE); and the water transport upon potential application ( Electroosmotic resistance coefficient, in mL / mol K + or mol / mol K + ).

[0080] In further experiments, using both the static electrolytic membrane electrolyzer and the system described above, we were able to demonstrate 100% CCE. In addition, SE was dropped separately into the portion taken from the anolyte chamber (ie not during potential appli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com