Method for rapidly detecting total number of bacterial colonies in production process of sauce

A technology for the total number of colonies and the production process, which is applied in the field of food hygiene testing, can solve the problems of reduced production efficiency of seasoning sauce and long detection time of the total number of colonies, etc., and achieve accurate and effective detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

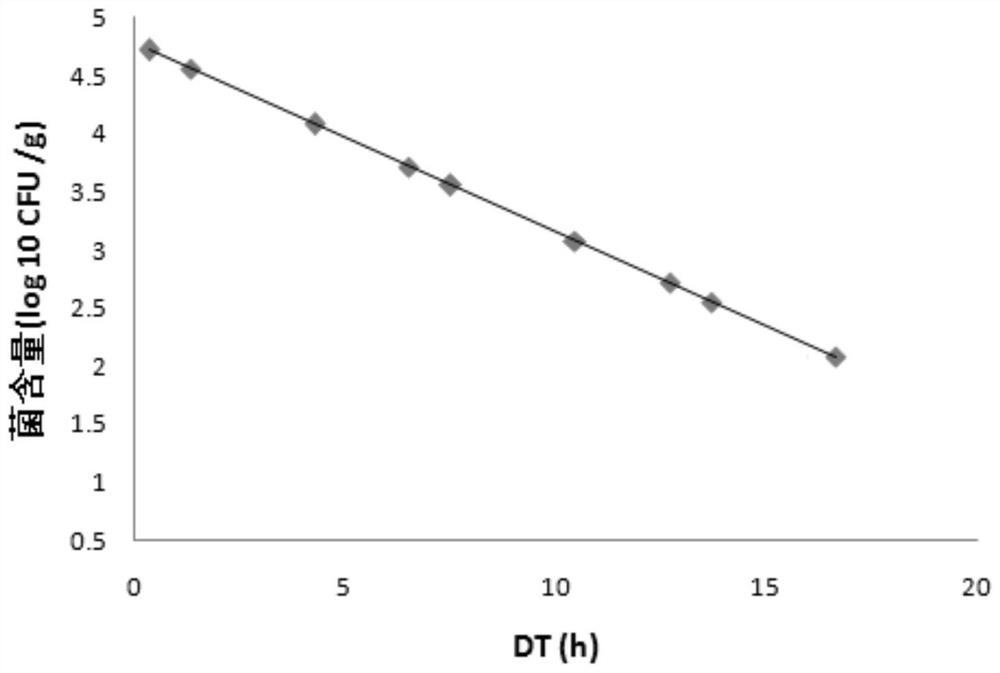

Method used

Image

Examples

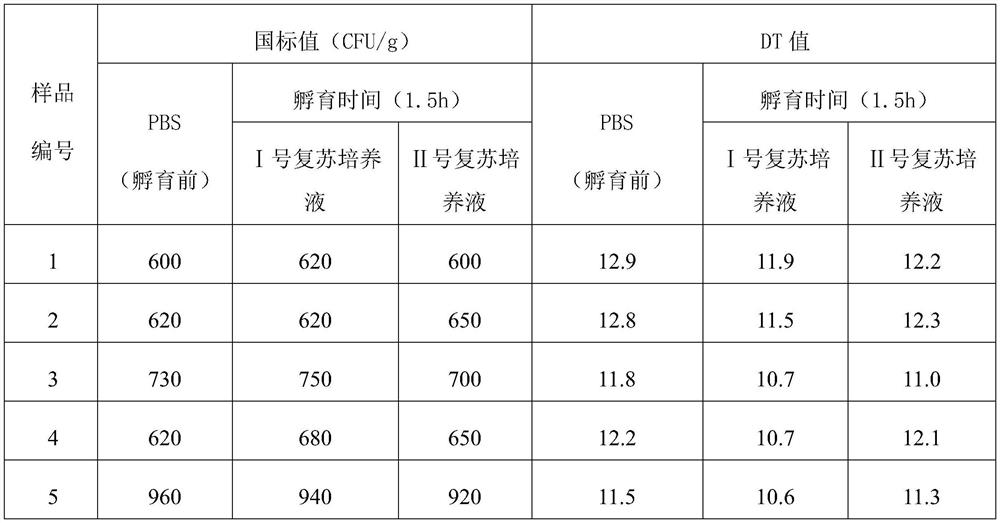

Embodiment 1

[0079] A method for rapid detection of the total number of bacterial colonies in the seasoning sauce production process, comprising the following steps:

[0080] (1) Prepare the resuscitation culture medium, its formula is: every 1000mL of distilled water contains 10.0g of peptone, 5.0g of sodium chloride, 9.0g of disodium hydrogen phosphate dodecahydrate, 1.5g of potassium dihydrogen phosphate, and 1g of L-alanine , while adding 1% Tween-80 by weight of the culture solution therein.

[0081] (2) Add seasoning sauce A to be tested into the recovery culture medium to dilute and shake, and then incubate in the recovery culture medium to repair the damaged flora and obtain the recovery liquid stock solution, wherein seasoning sauce A is Shrimp seasoning sauce; the specific steps are as follows:

[0082] Randomly select 20 batches of dried shrimp sauce to be tested, weigh 25g of each batch of samples, add them to 225mL of the above-mentioned resuscitated culture medium, shake for...

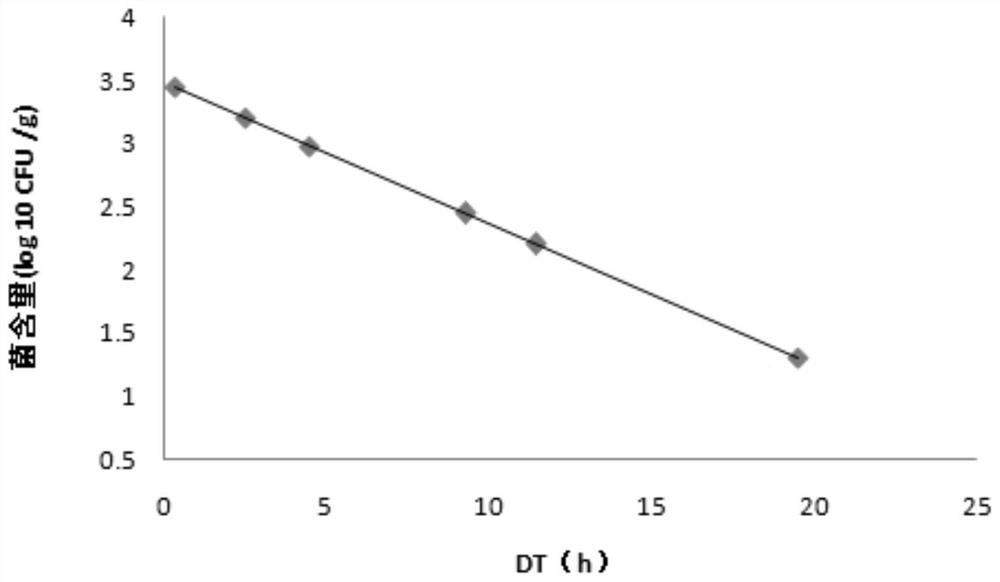

Embodiment 2

[0095](1) Prepare recovery culture medium, its formula is: every 1000mL of distilled water contains 11.0g of peptone, 5.5g of sodium chloride, 10.0g of disodium hydrogen phosphate dodecahydrate, 1.8g of potassium dihydrogen phosphate, and 2g of L-alanine , while adding 2% Tween-60 by weight of the culture solution therein.

[0096] (2) Add seasoning sauce B to be tested into the resuscitation culture medium to dilute and shake, and then incubate in the resuscitation culture medium to repair the damaged flora and obtain the original solution of the resuscitation liquid, wherein seasoning sauce B is Soybean paste: The specific steps are as follows: randomly take 20 batches of soybean paste samples to be tested, weigh 25g each, add to 150mL of the above-mentioned recovery culture medium, shake for 40s, and then incubate at 36°C for 1.0h.

[0097] (3) Take 1mL of resuscitation liquid stock solution and add it to the culture tube, then test it on the machine, and issue the DT time;...

Embodiment 3

[0106] (1) Prepare the resuscitation culture medium, its formula is: every 1000mL distilled water contains peptone 10.5g, sodium chloride 6.0g, dodecahydrate disodium hydrogen phosphate 9.6g, potassium dihydrogen phosphate 2.0g, L-alanine 1.5 g, while adding 1.5% Tween-80 of culture solution weight therein.

[0107] (2) Add the seasoning sauce C to be tested into the recovery culture medium to dilute and shake it, and then incubate in the recovery culture medium to repair the damaged flora and obtain the recovery liquid stock solution, wherein the seasoning sauce C is Fish sauce; the specific steps are as follows: Select 20 batches of samples of fish sauce to be tested, weigh 25g, add to 250mL of the above-mentioned recovery culture medium, shake for 60s, and then incubate at 35°C for 2.0h.

[0108] (3) Take 1mL of the resuscitation fluid stock solution and add it into the culture tube, then test it on the machine, and issue the DT time. Bring the DT value issued into the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com