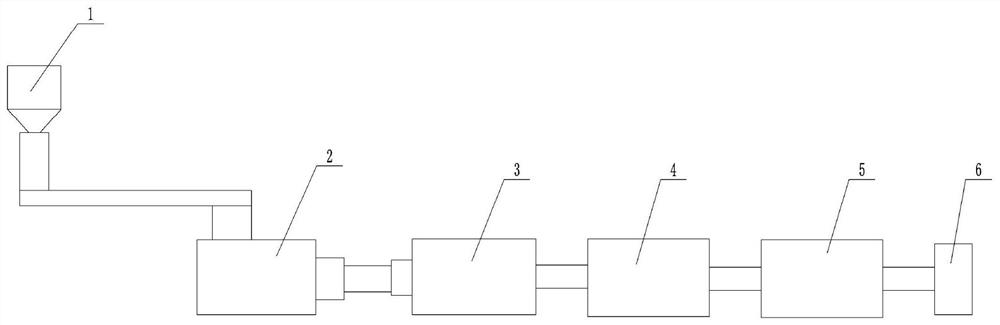

Pipe extrusion molding system

A technology of extrusion molding and extrusion molding machine, applied in the field of pipe extrusion molding system, which can solve the problems of low precision and poor pipe quality, and achieve the effects of saving energy, reducing energy consumption, and avoiding damage to precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is further described in detail through specific implementation methods:

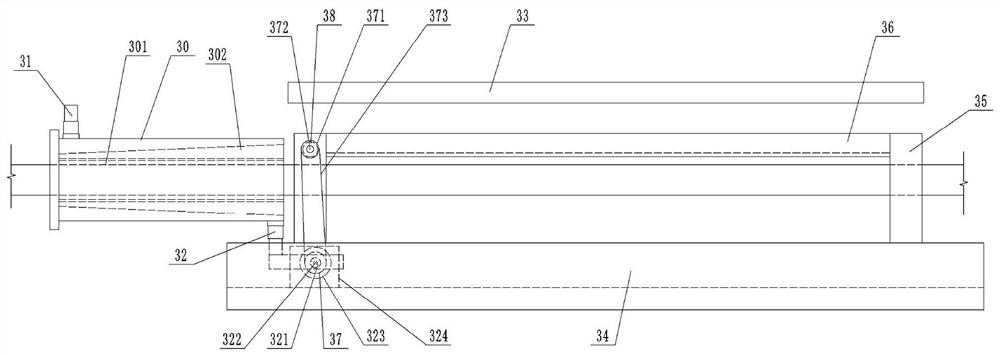

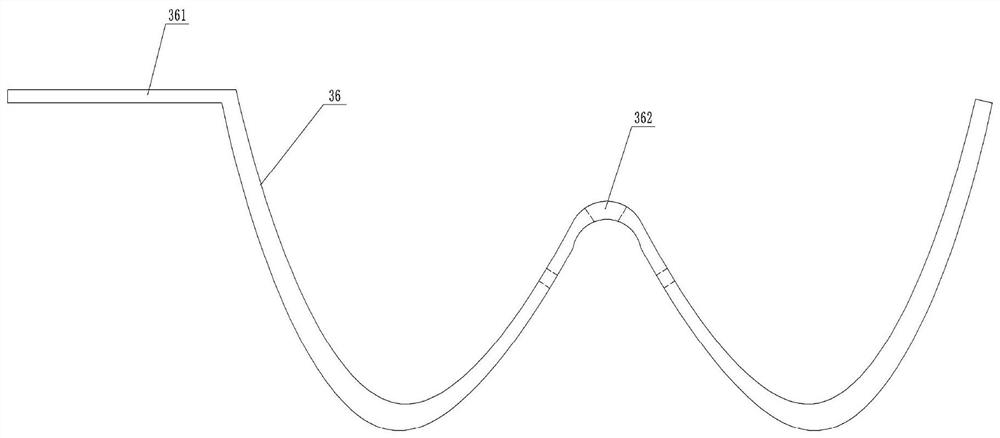

[0036] The reference signs in the accompanying drawings of the description include: mixing machine 1, extrusion molding machine 2, cooling equipment 3, traction equipment 4, cutting equipment 5, hole reaming equipment 6, cooling jacket 30, cooling zone 301, cooling cavity 302, Outlet pipe 31, water inlet pipe 32, single-suction pump wheel 321, rotating shaft 322, water wheel 323, support block 324, spray structure 33, water tank 34, bracket 35, speed limiting plate 36, connecting rod 361, bar mouth 362, Driving wheel 37, driven wheel 371, fulcrum 372, conveyor belt 373, cylindrical cam 38, mounting frame 40, support frame 41, transmission sprocket wheel 42, transmission chain 43, traction member 44, suction hole 441, inflation valve 45, air bag 451 , vent hole 452, mold cavity 453, vacuum structure 46, motor 47, main gear 471, driven shaft 472, slave gear 473, transmission rod 474, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com