Method for removing benzopyrene in flax extract

The technology of extract and benzopyrene is applied in the field of removal of benzopyrene in flax extract, and can solve the problems of uncontrollable loss of flax lignans, unsuitable removal of benzopyrene, high removal cost, etc. The effect of low cost, increased content and low removal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

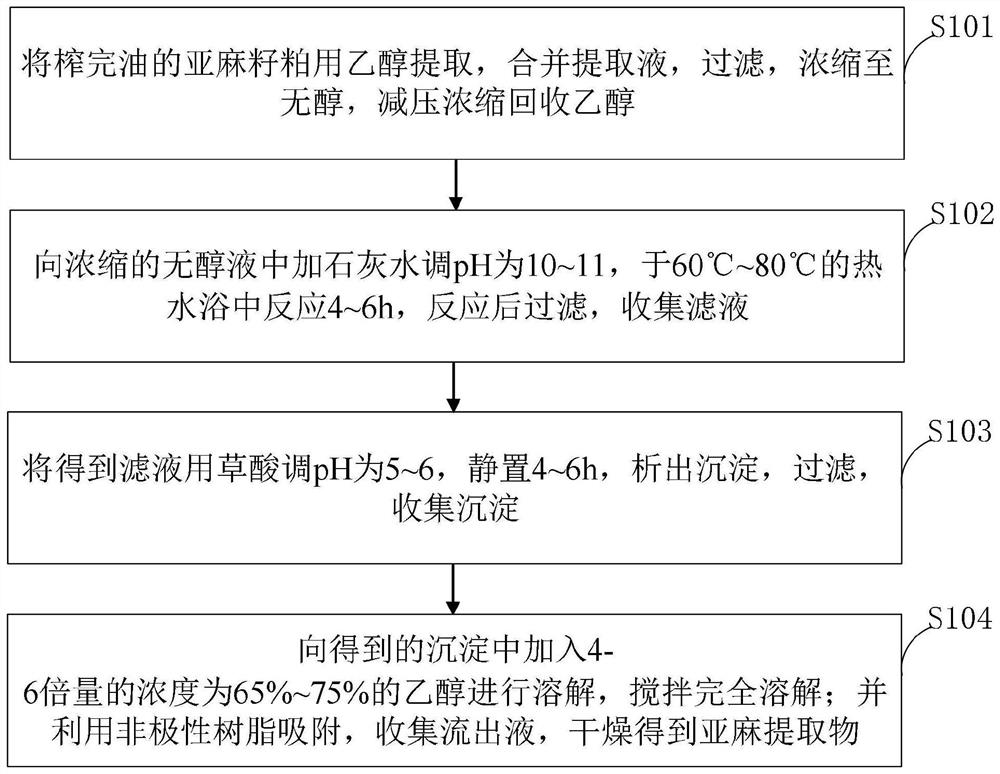

[0052] The method for removing benzopyrene in the flax extract provided by the embodiments of the present invention specifically includes:

[0053] (1) Ethanol extraction: take 200 g of linseed meal, extract with 75% ethanol, extract three times, 1.5 h each time, and the amount of extraction solvent is 8 / 6 / 6 times of the raw material. Combine the extracts, filter, concentrate the filtrate to no alcohol, and recover ethanol;

[0054] (2) Saponification: add lime water to the alcohol-free solution to adjust the pH to 11, react in a hot water bath, the hot water bath is 80 ° C, keep warm for 5 hours, and filter;

[0055] (3) acid adjustment: the filtrate is adjusted to pH 5 with oxalic acid, left to stand for 4 hours, precipitated, filtered, and collected;

[0056] (4) Alcohol dissolution: add 75% ethanol to dissolve the precipitate, the amount of ethanol added is 5 times of the precipitate, stir to dissolve completely.

[0057] (5) Column: PHD-100 non-polar resin is adsorbed o...

Embodiment 2

[0060] The method for removing benzopyrene in the flax extract provided by the embodiments of the present invention specifically includes:

[0061] (1) Ethanol extraction: take 500g of linseed meal, extract with 70% ethanol, extract three times, 1.5h / time, and the amount of extraction solvent is 10 / 8 / 6 times of the raw material. Combine the extracts, filter, concentrate the filtrate to no alcohol, and recover ethanol;

[0062] (2) Saponification: add lime water to the alcohol-free solution to adjust the pH to 11, react in a hot water bath, the hot water bath is 80 ° C, keep warm for 6 hours, and filter;

[0063] (3) acid adjustment: the filtrate is adjusted to pH 5 with oxalic acid, left to stand for 5 hours, precipitated, filtered, and collected;

[0064] (4) Alcohol dissolution: add 75% ethanol to dissolve the precipitate, the amount of ethanol added is 6 times of the precipitate, stir and dissolve completely.

[0065] (5) Putting on the column: LX-60 non-polar resin is ad...

Embodiment 3

[0068] The method for removing benzopyrene in the flax extract provided by the embodiments of the present invention specifically includes:

[0069] (1) Ethanol extraction: take 1000 g of linseed meal and extract with 65% ethanol for three times, 2 hours each time, and the amount of extraction solvent is 10 / 8 / 8 times of the raw material. Combine the extracts, filter, concentrate the filtrate to no alcohol, and recover ethanol;

[0070] (2) Saponification: add lime water to the alcohol-free solution to adjust the pH to 11, react in a hot water bath, the hot water bath is 85 ° C, keep warm for 4 hours, and filter;

[0071] (3) acid adjustment: the filtrate is adjusted to pH 5 with oxalic acid, left to stand for 4 hours, precipitated, filtered, and collected;

[0072] (4) Alcohol dissolution: add 75% ethanol to the precipitate to dissolve, the amount of ethanol added is 4 times of the amount of the precipitate, stir to dissolve completely.

[0073] (5) Putting on the column: D10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com