Preparation method of polymer dispersed liquid crystal film

A technology for dispersing liquid crystals and polymers, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of short service life, poor practicability, insufficient mechanical strength of polymer networks, etc., and achieve excellent mechanical properties and long service life. , good electro-optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

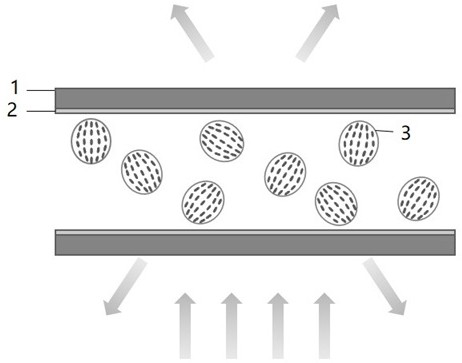

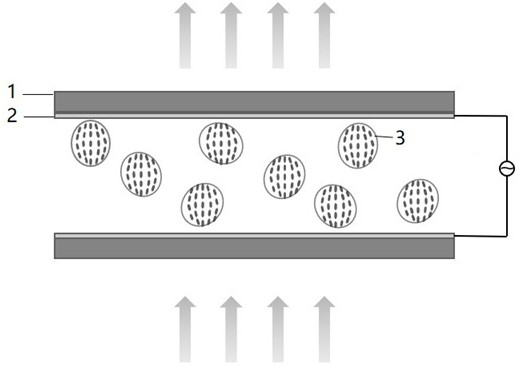

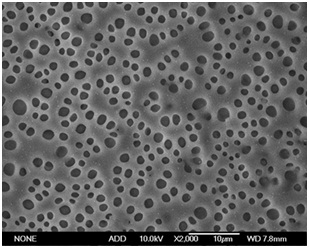

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in the preferred embodiment are only for convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

[0033] The invention provides a kind of preparation method of polymer dispersed liquid crystal film, comprises the following steps:

[0034] Step S1, mixing the raw materials according to the following mass percentage proportions to obtain a liquid crystal mixed solution:

[0035] Liquid crystal material 30-80%;

[0036] Mercaptan monomer 5-50%;

[0037] Acrylic monomer 5-50%;

[0038] 5-50% ethylenic polymerizable monomer;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com