Preparation method of degradable high-performance fiber reinforced epoxy resin-based composite material

A high-performance fiber and epoxy resin technology, which is applied in the preparation of high-performance resin-based composite materials, composite fiber recycling, and degradation fields, can solve the problem of fiber-reinforced body structure damage, harsh degradation conditions, and fiber-reinforced epoxy resin. The problem of difficult degradation of matrix composite materials and other problems, to achieve the effect of mild degradation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, 4,5-epoxyhexane-1,2-dicarboxylic acid diglycidyl ester and 4,4'-oxydiphthalic anhydride were purchased from Beijing Yinuokai Reagent Co., Ltd. Ethylene glycol was purchased from Sarn Chemical Technology (Shanghai) Co., Ltd. T300 carbon fiber woven fabric (GW3011) was purchased from Weihai Tuban Fiber Co., Ltd., China.

[0037] This embodiment includes a degradable, high-performance fiber-reinforced epoxy resin-based composite material preparation method and degradation steps, including the following steps:

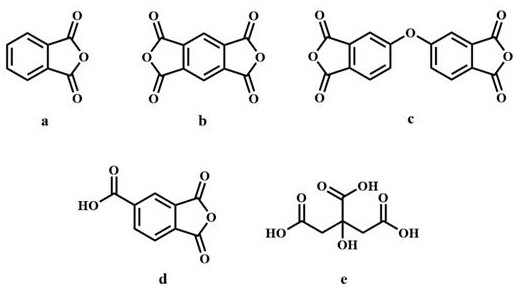

[0038] (1) Pretreatment of the epoxy resin and the curing agent containing the functional group participating in the effect of the adjacent group.

[0039] Preheat 4,5-epoxyhexane-1,2-dicarboxylic acid diglycidyl ester with a mole fraction of 30% at 85-100°C, add 4,4'-oxydiphthalate with a mole fraction of 70% Formic anhydride, keep stirring, and gradually raise the temperature until the solid is completely dissolved and mixed evenly.

[0040] (2...

Embodiment 2

[0044]In this example, 4,4'-diaminodiphenylmethane epoxy resin, pyromellitic dianhydride and phthalic anhydride were purchased from Beijing Yinuokai Reagent Co., Ltd. Ethylene glycol was purchased from Sarn Chemical Technology (Shanghai) Co., Ltd. T300 carbon fiber woven fabric (GW3011) was purchased from Weihai Tuban Fiber Co., Ltd., China.

[0045] This embodiment includes a degradable, high-performance fiber-reinforced epoxy resin-based composite material preparation method and degradation steps, including the following steps:

[0046] (1) Pretreatment of the epoxy resin and the curing agent containing the functional group participating in the effect of the adjacent group.

[0047] Preheat the 4,4'-diaminodiphenylmethane epoxy resin with a mole fraction of 40% at 85-100°C, and add a mixture of pyromellitic dianhydride and phthalic anhydride with a mole fraction of 60%, without Stop stirring, and gradually increase the temperature until the solids are completely dissolved ...

Embodiment 3

[0052] In this example, the hyperbranched epoxy resin was synthesized by reacting bisphenol A epoxy resin with 2-ethyl-2-(hydroxymethyl)-1,3-propanediol in a solvent-free condition in one step. Pyromellitic dianhydride was purchased from Beijing Yinuokai Reagent Co., Ltd. Ethylene glycol was purchased from Sarn Chemical Technology (Shanghai) Co., Ltd. Fiberglass woven cloth (EW250F) was purchased from Weihai Tudou Fiber Co., Ltd., China.

[0053] This embodiment includes a degradable, high-performance fiber-reinforced epoxy resin-based composite material preparation method and degradation steps, including the following steps:

[0054] (1) Pretreatment of epoxy resin and compounds containing ortho-group functional groups.

[0055] Preheat the hyperbranched epoxy resin with a mole fraction of 20% at 85-100°C, add pyromellitic dianhydride with a mole fraction of 80%, keep stirring, and gradually heat up until the solid is completely dissolved and mixed evenly.

[0056] (2) Pou...

PUM

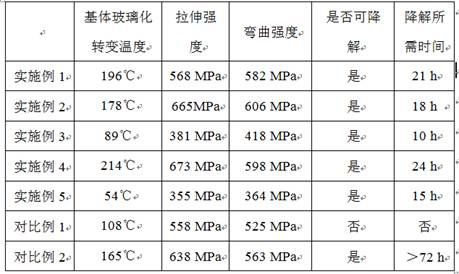

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com