Surface treatment process for reducing peel strength heat loss rate of electrolytic copper foil

A technology of heat loss rate and surface treatment, applied in the direction of electrolysis, electroforming, etc., can solve the problems of low anti-peel strength of electrolytic copper foil, reduce the heat loss rate of electrolytic copper foil anti-peel strength, high heat loss rate, etc., to avoid The effects of high dendrites, low heat loss rate of peel strength, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

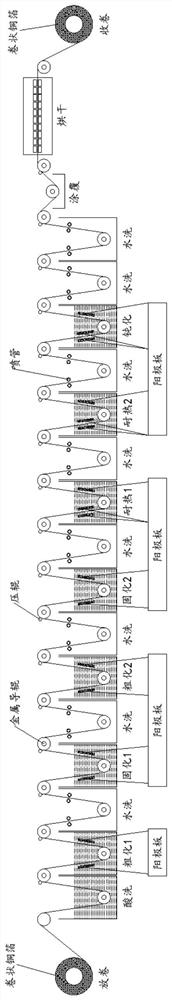

[0029] see figure 1 As shown, a surface treatment process to reduce the heat loss rate of the electrolytic copper foil anti-peel strength, the thickness of the copper foil is selected to be 12 μm, mainly including the following processes:

[0030] Copper foil unwinding, pickling, roughening 1, washing, curing 1, washing, roughening 2, washing, curing 2, washing, heat resistance 1, washing, heat resistance 2, washing, passivation, washing, coupling agent Coating, drying, copper foil winding;

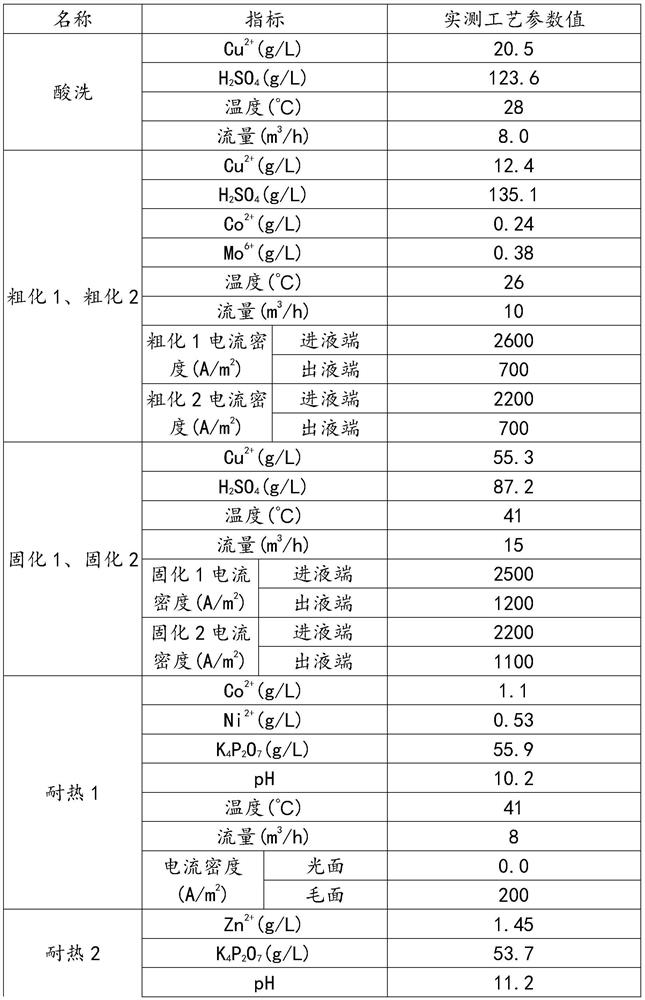

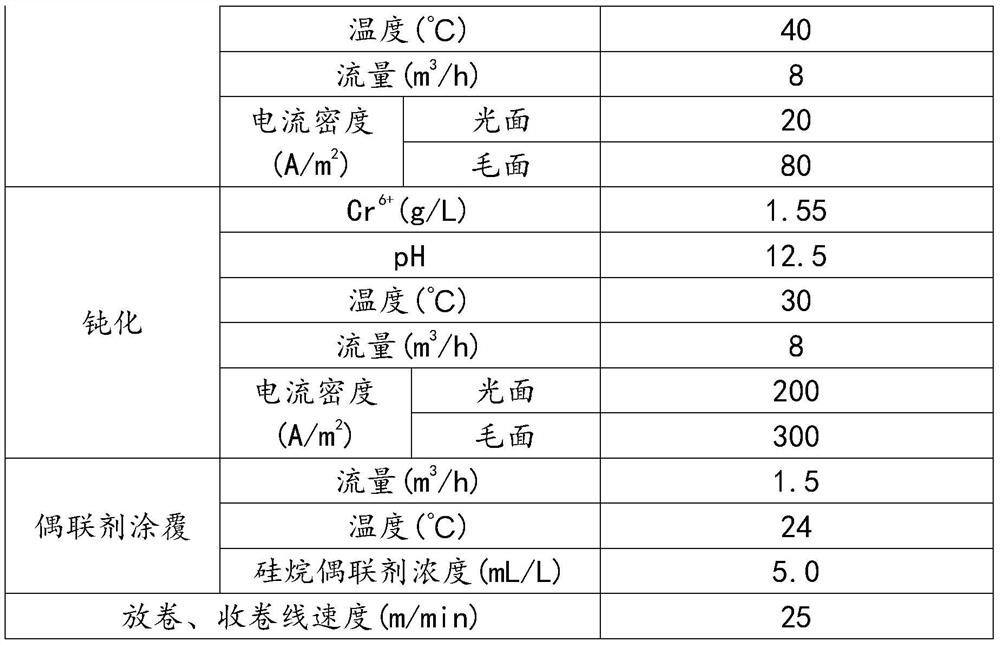

[0031] The measured process parameter values of each process are shown in Table 1 below:

[0032] Table 1

[0033]

[0034]

Embodiment 2

[0036] see figure 1 As shown, a surface treatment process for reducing the heat loss rate of the anti-peel strength of electrolytic copper foil, the thickness of the copper foil is selected as 18 μm, mainly includes the following processes:

[0037] Copper foil unwinding, pickling, roughening 1, washing, curing 1, washing, roughening 2, washing, curing 2, washing, heat resistance 1, washing, heat resistance 2, washing, passivation, washing, coupling agent Coating, drying, copper foil winding;

[0038] The measured process parameter values of each process are shown in Table 2 below:

[0039] Table 2

[0040]

[0041]

[0042]

Embodiment 3

[0044] see figure 1 As shown, a surface treatment process to reduce the heat loss rate of the electrolytic copper foil anti-peel strength, the thickness of the copper foil is selected to be 35 μm, mainly including the following processes:

[0045] Copper foil unwinding, pickling, roughening 1, washing, curing 1, washing, roughening 2, washing, curing 2, washing, heat resistance 1, washing, heat resistance 2, washing, passivation, washing, coupling agent Coating, drying, copper foil winding;

[0046] The measured process parameter values of each process are shown in Table 3 below:

[0047] table 3

[0048]

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com