Coarse cereal bread premixed flour, coarse cereal bread and making method of coarse cereal bread

A production method and technology of ready-mixed powder, which are applied in the directions of dough processing, pre-baked dough processing, baking, etc., can solve problems such as high-end technical content, and achieve the effects of delicate and soft taste, improved utilization rate, and soft finished product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

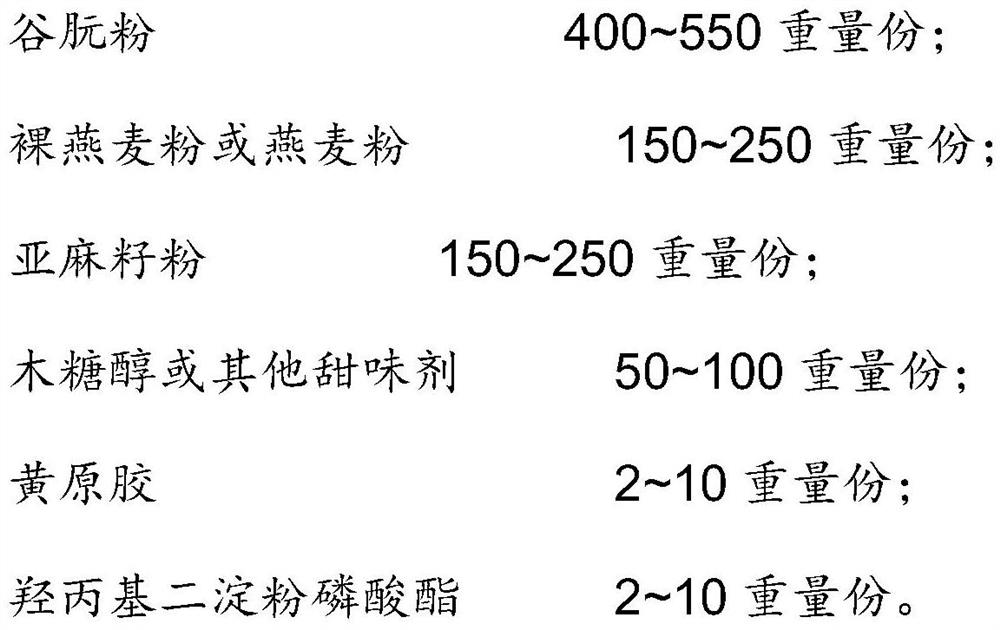

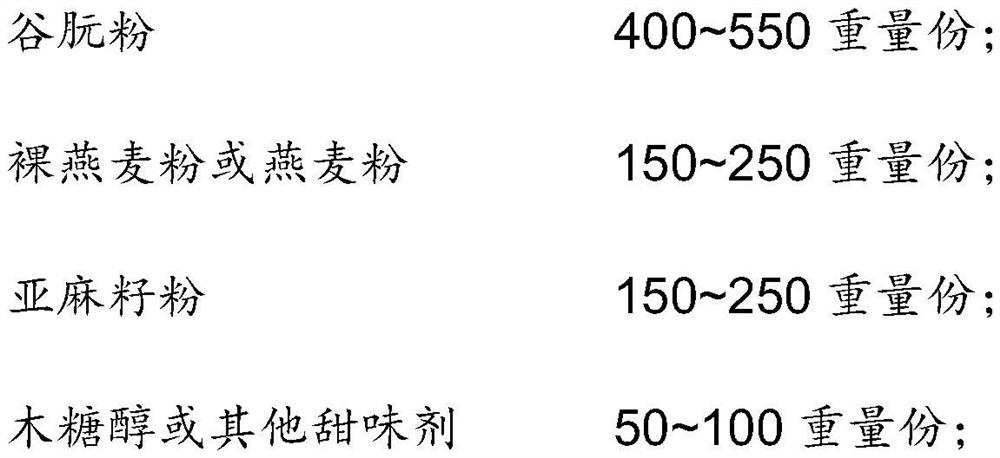

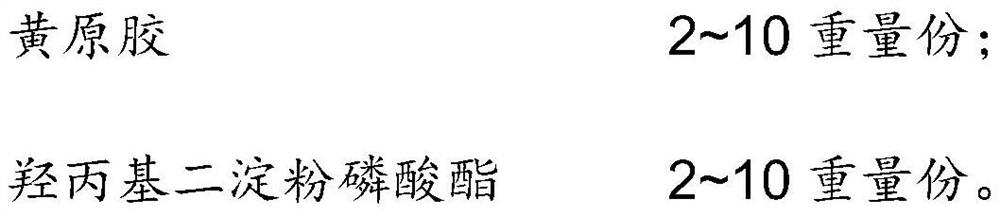

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, the preparation method of the multigrain cereal bread made based on the multigrain cereal premix powder is as follows:

[0048] Step 1, dough preparation: 1050 parts by weight of water, 1000 parts by weight of multigrain cereal premix powder, 25 parts by weight of low-sugar yeast, 150 parts by weight of whole egg liquid and 12 parts by weight of table salt in the formula are stirred until the gluten is fully expanded;

[0049] Wherein, in this step, when the dough is prepared, after the mixer is turned on, stir for 2 minutes at a slow gear, and then stir for 5 minutes at a fast gear, and the temperature of the dough after mixing is 28°C.

[0050] Step 2, loosen the dough: Stir and knead the dough, then knead the dough repeatedly until the surface is smooth, pour out the kneaded dough on the chopping board, and let it stand for 10 minutes;

[0051] Step 3: Divide and knead the dough: when dividing the dough, each is calculated as 35 parts by weight, a...

Embodiment 2

[0059] In this embodiment, the preparation method of the multigrain bread made based on the multigrain bread premix is as follows:

[0060] Step 1, dough preparation: 1050 parts by weight of water, 1000 parts by weight of miscellaneous grain bread premix, 25 parts by weight of low-sugar yeast, 150 parts by weight of whole egg liquid and 12 parts by weight of salt in the formula are stirred until the gluten is fully expanded;

[0061] Wherein, in this step, when the dough is prepared, after the mixer is turned on, stir for 2 minutes at a slow gear, and then stir for 5 minutes at a fast gear, and the temperature of the dough after mixing is 28°C.

[0062] Step 2, add dried fruit: after stirring, add 100 parts by weight of dried walnuts, and stir slowly for one minute until the dried fruit is uniform; among them, the above-mentioned dried fruit can be selected according to taste requirements, if it can be replaced with dried cranberries , dried mangoes, dried apricots, etc.

...

Embodiment 3

[0072] In this embodiment, the preparation method of the multigrain bread made based on the multigrain bread premix is as follows:

[0073] Step 1, dough preparation: 1050 parts by weight of water, 1000 parts by weight of multigrain bread premix powder, 20 parts by weight of matcha powder, 10 parts by weight of barley grass powder, 25 parts by weight of low-sugar yeast, and 150 parts by weight of whole egg liquid in the formula , 12 parts by weight of table salt and stir until the gluten is fully expanded;

[0074] Adding matcha powder to the premix powder can increase the taste of the finished product, and it will have a faint tea aroma when eaten. Although matcha powder can adjust the color, it will fade during the baking process. Therefore, adding barley grass powder can make the color of the bread more beautiful.

[0075] Wherein, in this step, when the dough is prepared, after the mixer is turned on, stir for 2 minutes at a slow gear, and then stir for 5 minutes at a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com