Novel batching kettle for preparing urea-fatty alcohol mixed solution and use method of novel batching kettle

A technology of fatty alcohol and mixed liquid, which is applied in mixers, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problems of raw material waste and low batching efficiency, and achieve small equipment investment, waste reduction, and occupancy The effect of small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

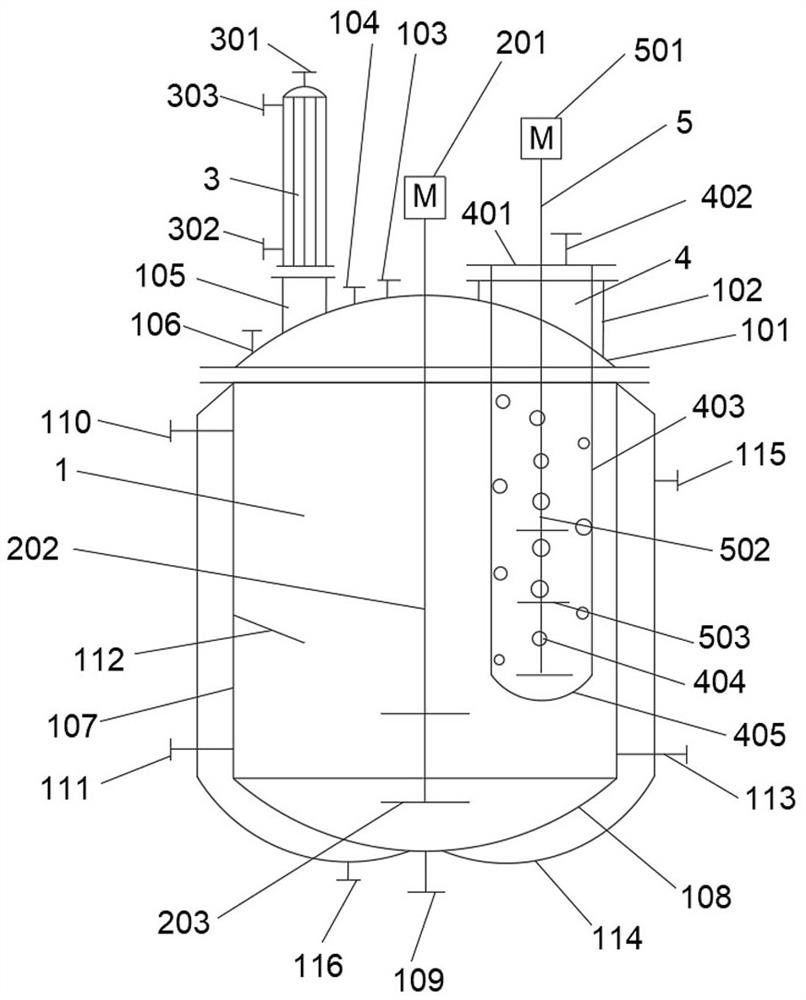

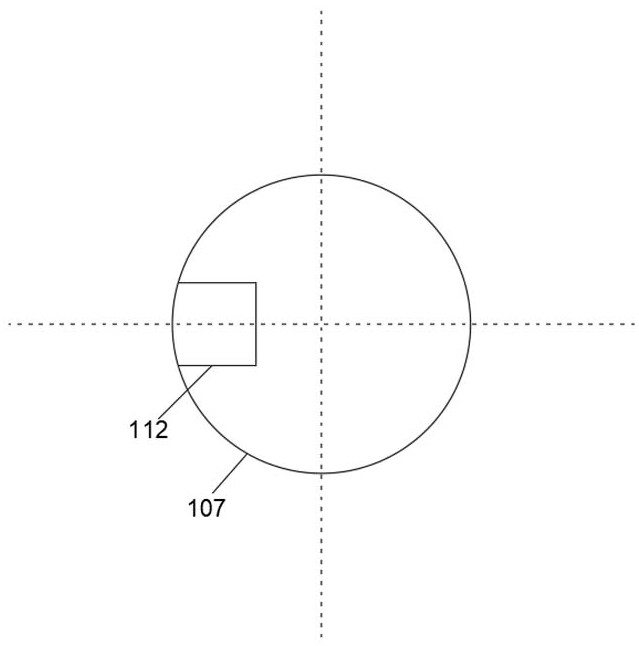

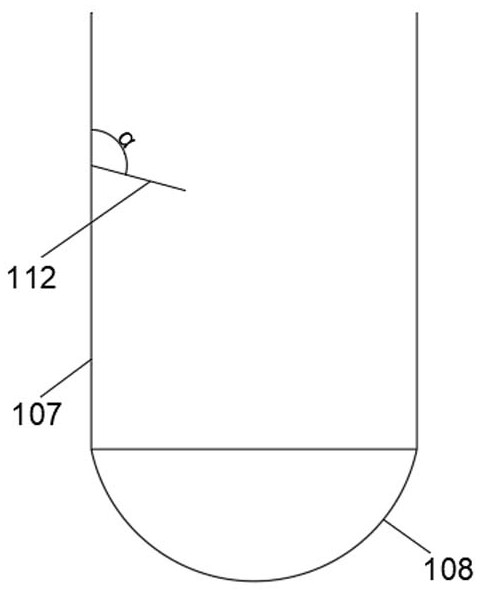

[0030] Such as Figure 1-5 As shown, the embodiment of the present invention provides a novel batching tank for preparing urea fatty alcohol mixed liquid, comprising a mixing tank 1, a mixing agitator 2, a condenser 3, a shearing cylinder 4, and a shearing agitator 5; the mixing tank 1 consists of The upper head 101 of the mixing tank, the barrel body 107 of the mixing tank and the lower head 108 of the mixing tank; the upper head 101 of the mixing tank is provided with a shear cylinder insertion port 102, a pressure gauge interface 103, a fatty alcohol inlet 104, and a gas phase channel 105 and the catalyst inlet 106; the lower head 108 of the mixing tank is provided with a mixing tank discharge port 109; Thermometer interface 113, anti-sinking baffle 112 is provided inside the mixing tank cylinder 107; mixing tank jacket 114 is provided outside the mixing tank cylinder 107 and the mixing tank lower head 108; a heating medium is provided on the mixing tank jacket 114 outlet ...

Embodiment 2

[0042] A new batching kettle for preparing urea fatty alcohol mixture, the angle α between the anti-sinking baffle 112 and the mixing tank cylinder 107 is 95°, its length is 1 / 3 of the diameter of the mixing tank cylinder 107, and its width is 3 times the diameter of the catalyst inlet 106, the vertical distance between the cross-section of the end and the lower head 108 of the mixing tank is 1 / 3 of the height of the mixing tank body 107, and the shearing cylinder body 403 is provided with micropores 404 with a diameter of 1 mm , the opening rate is 70% of the shearing cylinder body 403; the shearing cylinder lower head 405 is also provided with micropores 404 with a diameter of 1mm, and the opening rate is 70% of the shearing cylinder body 403; the shearing cylinder 4 The diameter is 1 / 7 of the diameter of the mixing tank 1, and the distance between the lower head 405 of the shearing cylinder inserted into the mixing tank 1 and the connection between the lower head 108 of the ...

Embodiment 3

[0045] For the new batching still of preparation urea fatty alcohol mixture, as described in embodiment 1, the included angle α of anti-vertical sinking baffle 112 and mixing tank barrel 107 is 92 °, and its length is 107 diameters of mixing tank barrel 1 / 4, its width is 2 times of the diameter of the catalyst inlet 106, the vertical distance between the cross-section of the end and the bottom head 108 of the mixing tank is 3 / 5 of the height of the mixing tank body 107, and the shearing cylinder body 403 is provided with There are micropores 404 with a diameter of 0.75mm, and the opening rate is 40% of the shearing cylinder body 403; the lower head 405 of the shearing cylinder is also provided with micropores 404 with a diameter of 1mm, and the opening rate is 40% of the shearing cylinder body. 35% of 403; the diameter of the shearing cylinder 4 is 1 / 5 of the diameter of the mixing tank 1, and the lower head 405 of the shearing cylinder inserted into the mixing tank 1 is the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com