Process and equipment for continuously producing selenium dioxide

A technology of selenium dioxide and production process, applied in the chemical industry, sustainable manufacturing/processing, selenium/tellurium oxide/hydroxide, etc., can solve the problems of intermittent production of selenium dioxide, environmental pollution, etc., and achieve occupational hygiene The effect of good conditions, high product yield and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

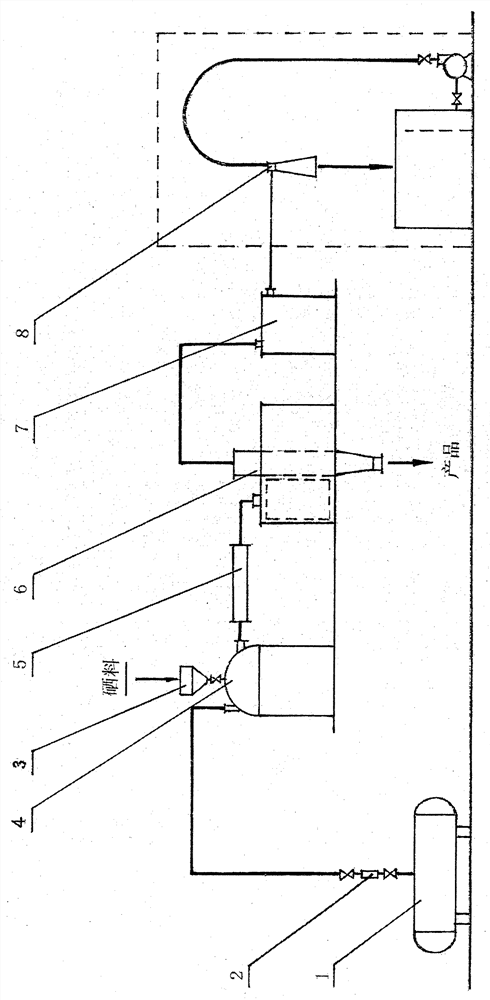

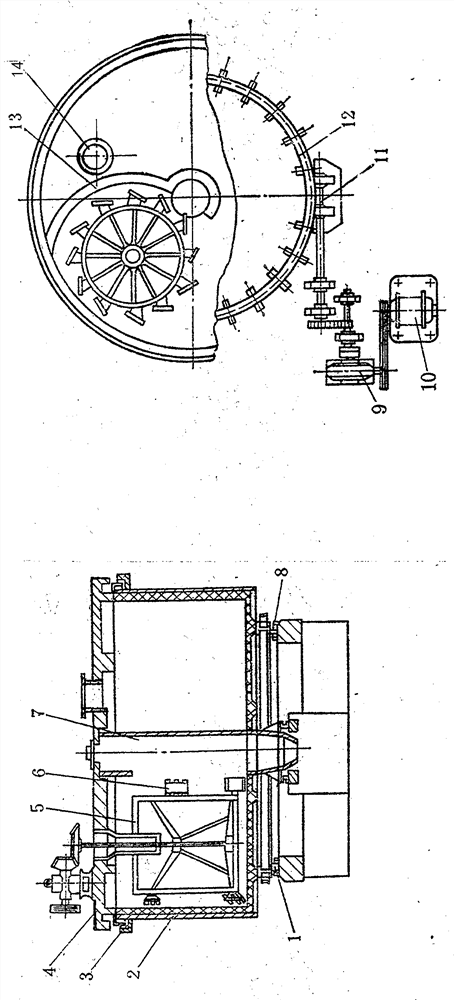

[0027] A continuous production process for selenium dioxide, comprising the steps of:

[0028] 1. Add 50kg of selenium material from the hopper 3 into the oxidation furnace 4, close the feed valve, and seal it;

[0029] 2. The oxidation furnace 4 is energized and heated, and the temperature rises to 270°C;

[0030] 3. Open the equipment or valves in the order of vacuum pump → oxygen → sublimator → rotary crystallization chamber, and maintain the negative pressure of the system at -10mmH 2 O column left and right;

[0031] 4. Oxygen is passed into the oxidation furnace 4 after flow meter 2 is metered, and reacts with selenium to generate gaseous selenium dioxide;

[0032] 5. When the temperature of the oxidation furnace 4 reaches 500°C, the heating is gradually stopped, and the reaction heat is used to maintain the oxidative combustion to continue, feeding once per hour, and the feeding amount is 30kg;

[0033] 6. Control the temperature of the sublimator between 450 and 500...

Embodiment 2

[0038] A continuous production process for selenium dioxide, comprising the steps of:

[0039] 1. Add 75kg of selenium material from the hopper 3 into the oxidation furnace 4, close the feed valve, and seal it;

[0040] 2. The oxidation furnace 4 is energized and heated, and the temperature rises to 285°C;

[0041] 3. Open the equipment or valves in the order of vacuum pump→oxygen→sublimator→rotary crystallization chamber, and maintain the negative pressure of the system at -30mmH 2 O column left and right;

[0042] 4. Oxygen is passed into the oxidation furnace 4 after flow meter 2 is metered, and reacts with selenium to generate gaseous selenium dioxide;

[0043] 5. When the temperature of the oxidation furnace 4 reaches 500°C, the heating is gradually stopped, and the reaction heat is used to maintain the oxidative combustion to continue, feeding once every 1.5 hours, and the feeding amount is 45kg;

[0044]6. Control the temperature of the sublimator between 450 and 500...

Embodiment 3

[0049] A continuous production process for selenium dioxide, comprising the steps of:

[0050] 1. Add 100kg of selenium material from the hopper 3 into the oxidation furnace 4, close the feed valve, and seal it;

[0051] 2. Turn on the electric heater 4 of the oxidation furnace, and the temperature rises to 300°C;

[0052] 3. Open the equipment or valves in the order of vacuum pump→oxygen→sublimator→rotary crystallization chamber, and maintain the negative pressure of the system at -50mmH 2 O column left and right;

[0053] 4. Oxygen is passed into the oxidation furnace 4 after flow meter 2 is metered, and reacts with selenium to generate gaseous selenium dioxide;

[0054] 5. When the temperature of the oxidation furnace 4 reaches 500°C, the heating is gradually stopped, and the reaction heat is used to maintain the oxidative combustion to continue, feeding once every 2 hours, and the feeding amount is 60kg;

[0055] 6. Control the temperature of the sublimator between 450 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com