Preparation method of m-ethylaniline

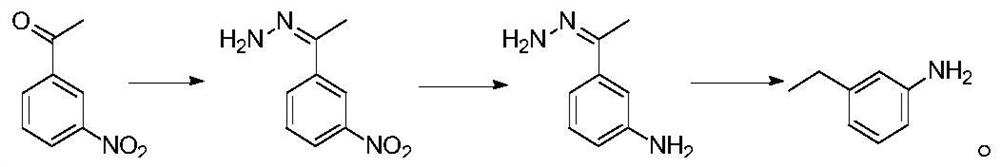

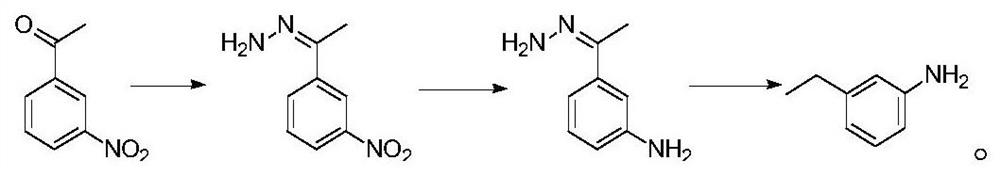

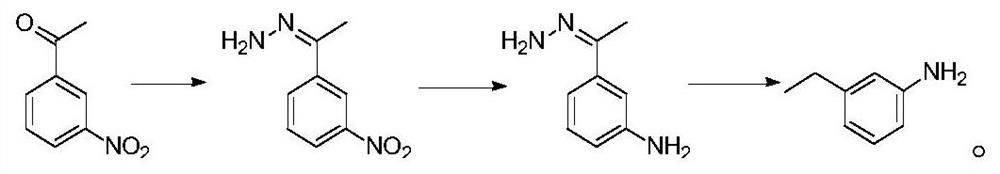

A technology for ethylaniline and nitroacetophenone, which is applied in the directions of preparing amino compounds from amines, preparing hydrazones, organic chemistry, etc., can solve problems such as heat amplification, difficulty in controlling safety, unfavorable industrial production, etc., and achieves easy operation, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method for m-ethylaniline, comprising the following steps:

[0022] Step 1. Add 80g of m-nitroacetophenone into a 500ml three-necked flask, add 160ml of methanol, heat to about 65°C, then add 36g of hydrazine hydrate, and continue to heat and reflux for 1.5 hours; after the reaction is completed, the reaction solution is directly used in the following one step reaction;

[0023] Step 2: Add the reaction solution into the hydrogenation reactor, add 0.2g of palladium carbon, pressurize the hydrogen to 0.25mpa, and react at 50-60°C for 2 hours, and the reaction ends;

[0024] Step 3. Keep the reactant obtained in step 2 warm at 45-55°C, let it stand, and extract the supernatant; add it to a 500ml three-necked bottle, add 40g of potassium hydroxide to it for heating reaction, heat and keep the reaction at 90°C to No fraction distilled out, continue to heat up to 120°C to react until no fraction distilled out, continue to heat up to 150°C to react, and the rea...

Embodiment 2

[0034] A preparation method for m-ethylaniline, comprising the following steps:

[0035] Step 1. Add 80g of m-nitroacetophenone into a 500ml three-necked flask, add 160ml of methanol, heat to about 65°C, then add 36g of hydrazine hydrate, and continue to heat and reflux for 1.5 hours; after the reaction is completed, the reaction solution is directly used in the following one step reaction;

[0036] Step 2: Add the reaction solution into the hydrogenation reactor, add 0.2g of palladium carbon, pressurize the hydrogen to 0.25mpa, and react at 50-60°C for 2 hours, and the reaction ends;

[0037] Step 3. Keep the reactant obtained in step 2 warm at 45-55°C, let it stand, and extract the supernatant; add it to a 500ml three-necked bottle, add 40g of potassium hydroxide to it for heating reaction, heat and keep the reaction at 90°C to No fraction distilled out, continue to heat up to 120°C to react until no fraction distilled out, continue to heat up to 150°C to react, and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com