Degradable composite material with lasting fragrance, preparation method and application thereof

A composite material and long-lasting technology, which is applied in the field of preparation and degradable composite materials, can solve the problems of easy precipitation, insufficient rigidity, uneven fragrance diffusion rate, etc., and achieve excellent mechanical properties, shorten migration path, and sufficient fragrance diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

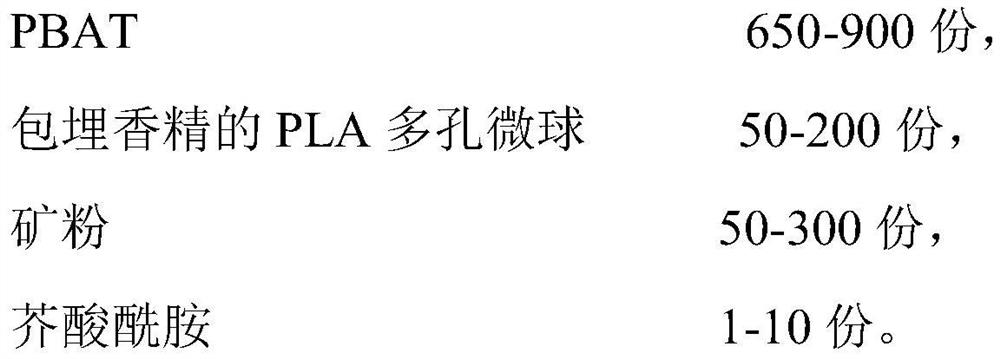

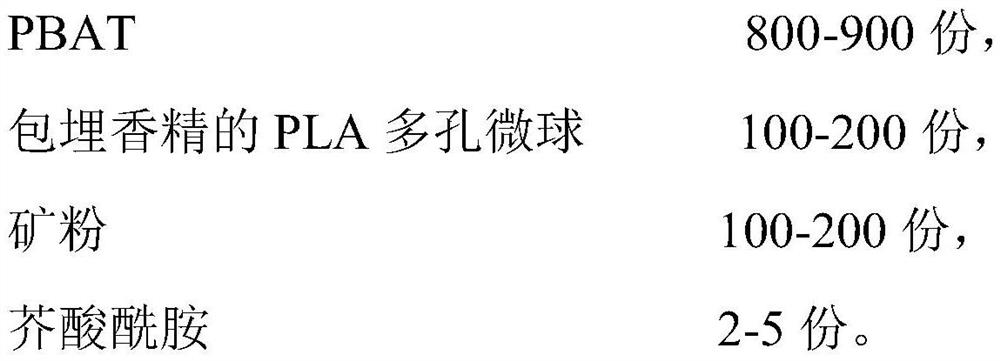

Method used

Image

Examples

preparation Embodiment 1

[0053] [Preparation Example 1] Preparation of PLA porous microspheres A

[0054] Will NH 4 HCO 3 Add 50g / L to 125mL water to prepare an aqueous solution. This aqueous solution was added to a 400 mL chloroform solution containing 12.5 g of PLA, and emulsified into a main emulsifier. Pour the main emulsifier into 15L PVA aqueous solution containing 1g / L immediately to form a double emulsion, and stir at 25°C for 8h. A 170-mesh filter was used to separate the filtrate, and finally the obtained PLA porous microspheres A were washed three times with deionized water, and freeze-dried for future use. It can be seen from the test that the PLA porous microsphere A has an average particle diameter of 160 μm and a porosity of 77%.

Embodiment 2

[0055] [Preparation Example 2] Preparation of PLA Porous Microspheres B

[0056] Will NH 4 HCO 3 Add 30g / L to 125mL water to prepare an aqueous solution. This aqueous solution was added to 400 mL of ethyl acetate solution containing 5 g of PLA, and emulsified into a main emulsifier. Pour the main emulsifier into 15L of PVA aqueous solution containing 0.5g / L immediately to form a double emulsion, and stir at 25°C for 5h. A 170-mesh filter was used to separate the filtrate, and finally the obtained PLA porous microspheres A were washed three times with deionized water, and freeze-dried for future use. It can be seen from the test that the average particle diameter of the PLA porous microsphere A is 105 μm and the porosity is 34%.

Embodiment 3

[0057] [Preparation Example 3] Preparation of PLA Porous Microspheres C

[0058] Will NH 4 HCO 3 Add 70g / L to 125mL water to prepare an aqueous solution. This aqueous solution was added to 400 mL of dichloromethane solution containing 20 g of PLA, and emulsified into a main emulsifier. Pour the main emulsifier into 15L of 3g / L PVA aqueous solution immediately to form a double emulsion, and stir at 25°C for 5h. A 170-mesh filter was used to separate the filtrate, and finally the obtained PLA porous microspheres A were washed three times with deionized water, and freeze-dried for future use. It can be seen from the test that the average particle diameter of the PLA porous microsphere A is 570 μm and the porosity is 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com