Antistatic dynamic vulcanized silicone rubber thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and dynamic vulcanization technology, applied in the field of elastomer materials, can solve problems such as easy agglomeration, material performance degradation, and poor compatibility of matrix materials, so as to improve antistatic performance, improve compatibility, and avoid stress defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0058] Surface modification of carbon-based antistatic fillers: place graphite or graphene in toluene solvent and ultrasonically disperse at room temperature for 30 minutes, wherein the weight ratio of carbon-based antistatic fillers to toluene is 1:15 to obtain carbon-based antistatic fillers Dispersion liquid; Then heat up to 80°C and use the silane coupling agent γ-aminopropyltrimethoxysilane KH-550 whose mass is 2 times that of graphite or graphene and the catalyst triethylamine whose mass is 1 / 5 of graphite or graphene Add amine dropwise to the dispersion liquid, stir and react at 80°C for 12 hours, then filter with suction, wash (wash with a mixture of toluene and ethanol), and dry (80°C, 10 hours) to obtain modified graphite or graphene Antistatic filler.

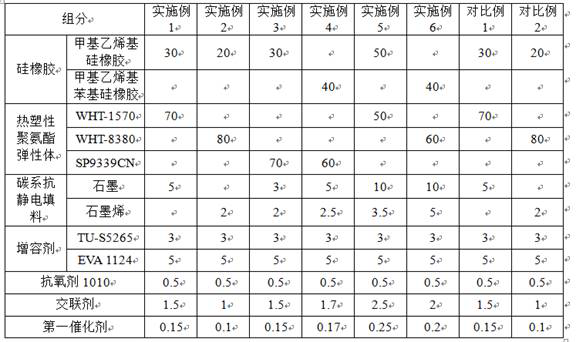

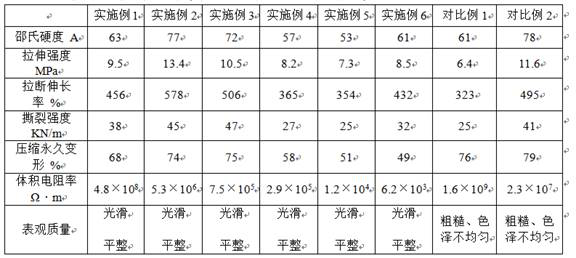

[0059] Table 1 is the raw material composition formula (unit: parts by weight) of each embodiment and each comparative example

[0060]

[0061] Preparation methods include:

[0062] Step 1. Pre-mixing of rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com