Piezoresistive pressure sensor design method considering temperature influence

A technology of a pressure sensor and a design method, which is applied in the field of measurement and testing, and can solve the problems of different resistance changes of piezoresistors, sensitivity changes, and non-uniform initial resistance values of four piezoresistors, etc., achieving fast calculation and good versatility , to avoid the effect of complex integrals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A piezoresistive pressure sensor design method considering the influence of temperature. When designing the piezoresistive pressure sensor, the thermal zero drift and thermal sensitivity drift of the piezoresistor are introduced to analyze the performance of the entire temperature range, which is convenient for subsequent effective temperature compensation;

[0060] The thermal zero point drift and thermal sensitivity drift are obtained by inputting the relationship between resistivity ρ and temperature under different doping concentrations and the relationship between piezoresistive coefficient π and temperature under different doping concentrations into the finite element software COMSOL to construct In the structural model of the piezoresistive pressure sensor, the static output characteristic curve and temperature drift characteristic curve are obtained by solving, and the thermal zero point drift and thermal sensitivity drift are obtained;

[0061] The electrical in...

Embodiment 2

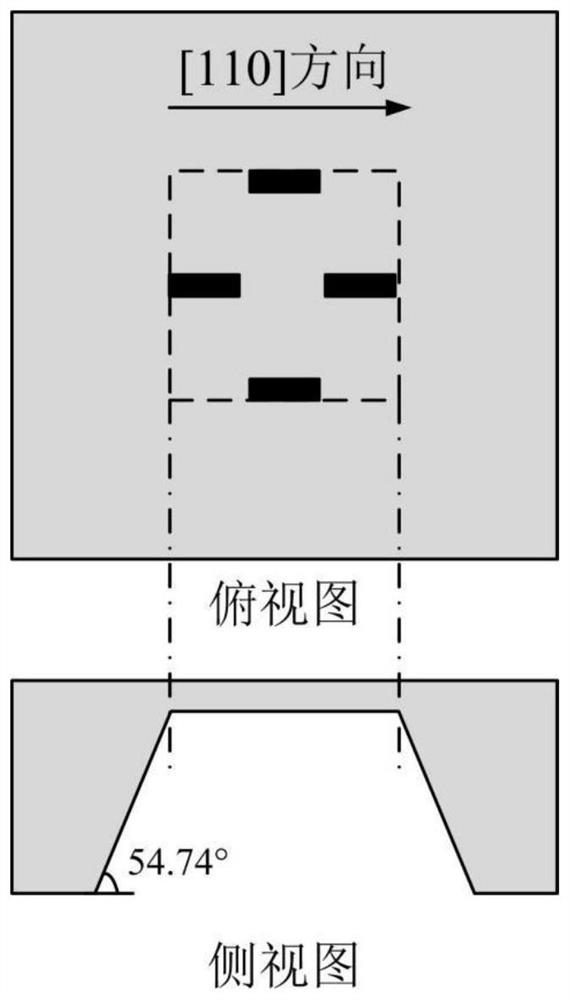

[0084] Such as figure 1 As shown, the present invention provides a piezoresistive pressure sensor design method considering the influence of temperature, and its calculation example selects p-type silicon piezoresistive strips placed in the [110] direction of the n-type silicon (100) wafer.

[0085] Features include:

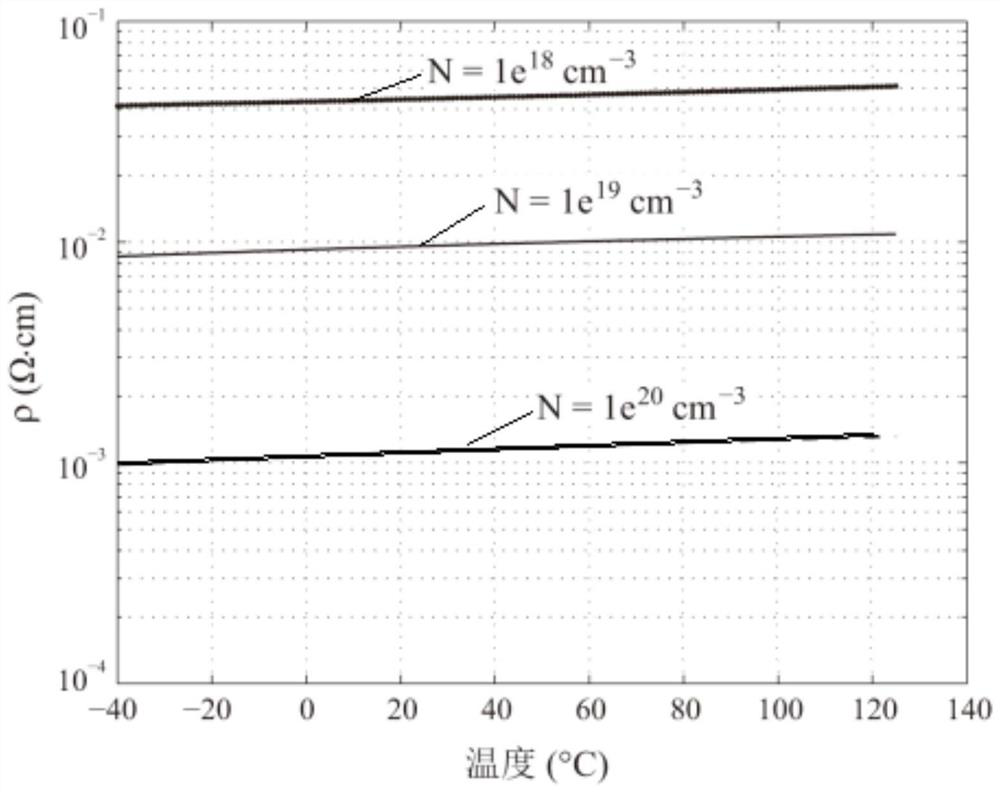

[0086] The resistivity ρ of p-type silicon is inversely proportional to the product of the doping concentration and the average carrier mobility, which is a function of the doping concentration and temperature. The expression of the carrier mobility is obtained by using a semi-empirical mathematical formula, and different The relationship between the resistivity ρ and the temperature under the doping concentration;

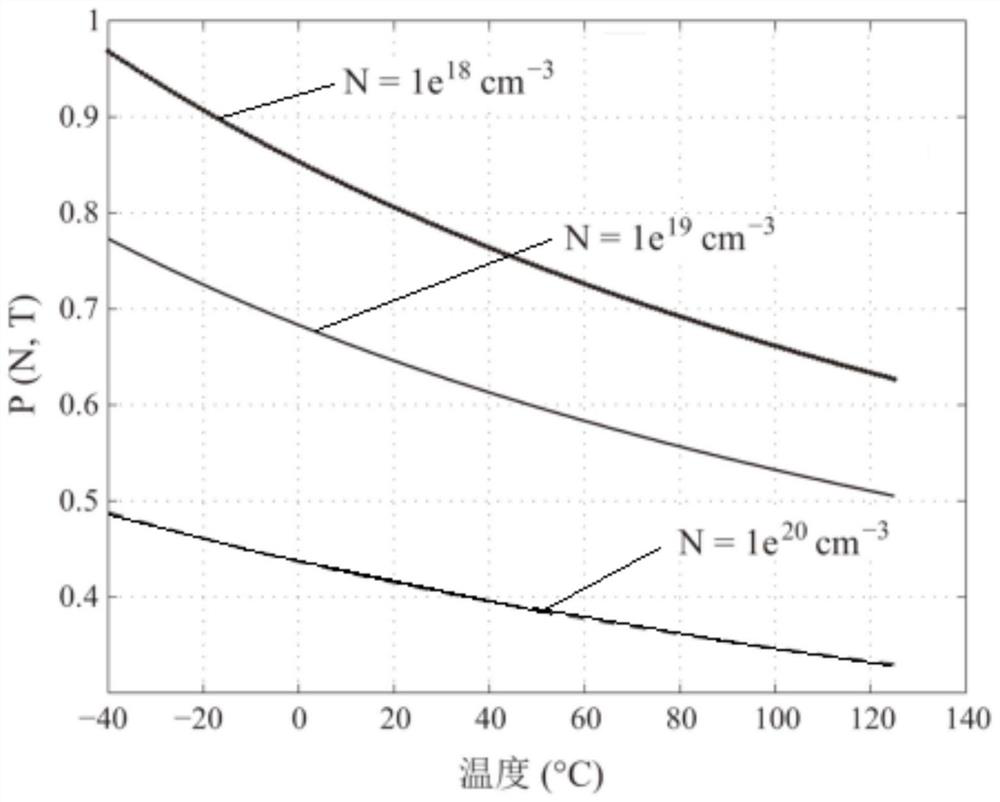

[0087] The piezoresistive coefficient π of p-type silicon is also a function of doping concentration and temperature. It is often expressed as the product of the piezoresistive coefficient and the piezoresistive correction factor P at room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com