Method for reducing polycrystalline silicon critical dimension loss caused by photoetching photoresist reworking

A critical dimension and polysilicon technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of polysilicon critical dimension reduction, yield loss, line width loss, etc., to improve polysilicon critical dimension reduction, The effect of reducing production costs and increasing critical dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

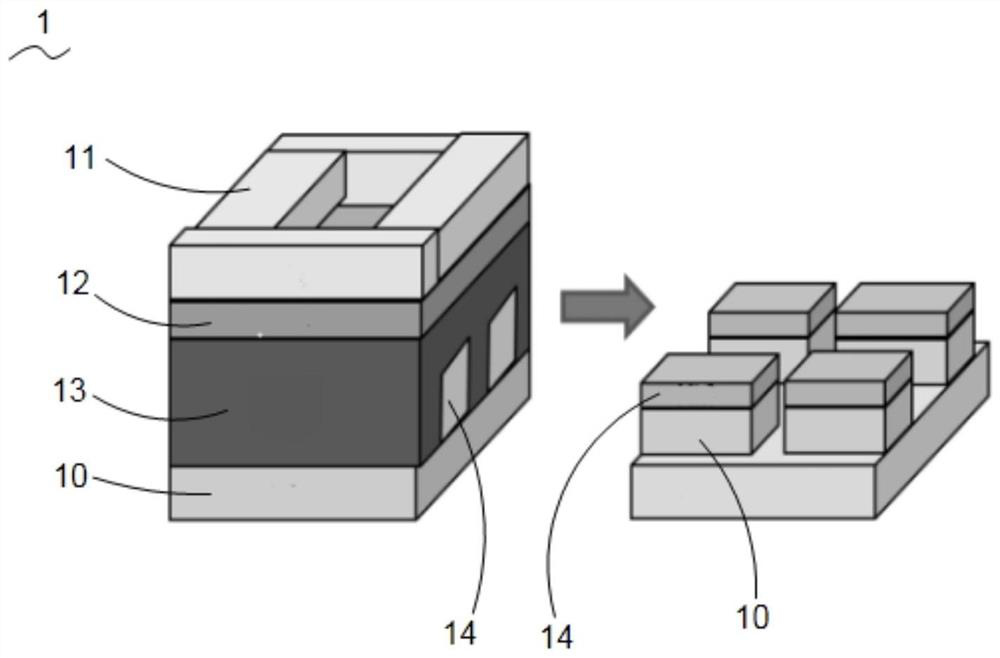

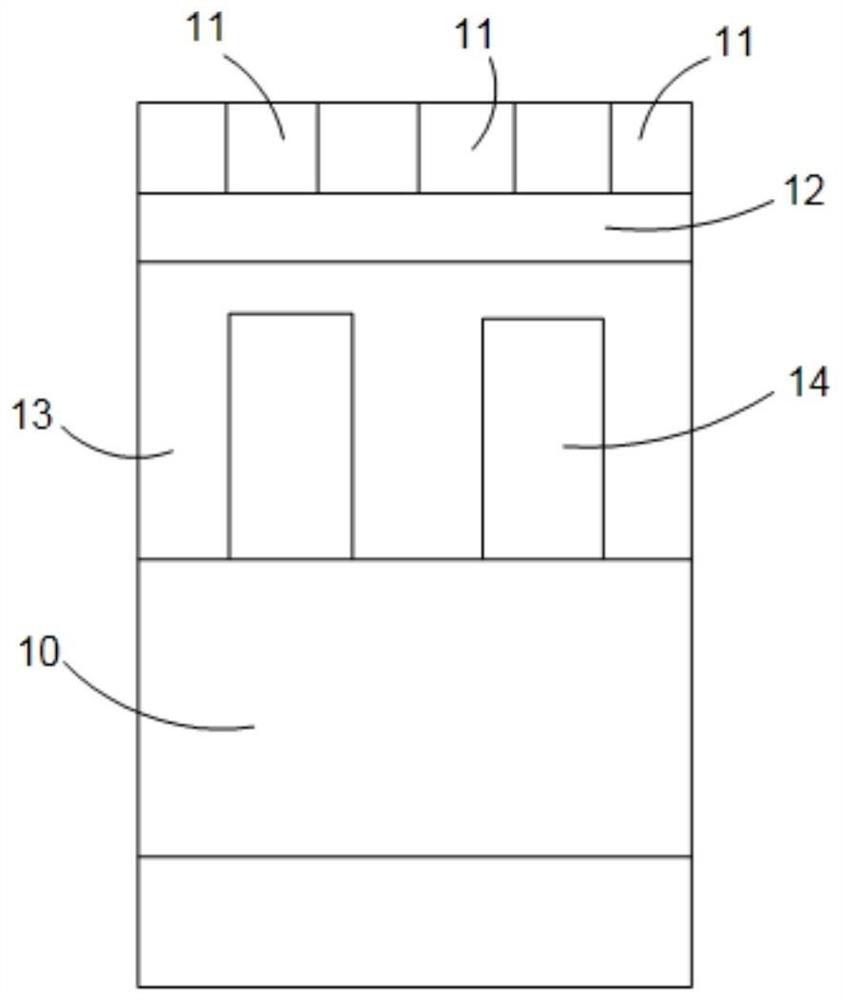

[0026] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

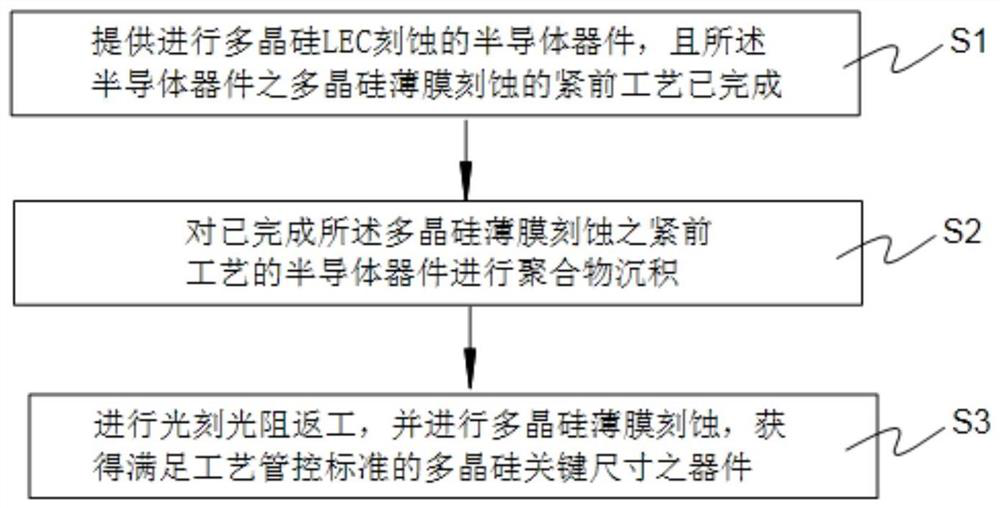

[0027] see figure 1 , figure 1 Shown is a flow chart of the method for reducing polysilicon critical dimension loss caused by photolithography and photoresist rework in the present invention. The method for reducing polysilicon critical dimension loss caused by photolithography and photoresist rework includes:

[0028] Executing step S1: providing a semiconductor device for polysilicon LEC etching, and the process immediately before the polysilicon film etching of the semiconductor device has been completed;

[0029] Executing step S2: performing polymer deposition on the semiconductor device that has completed the process immediately before the etching of the polysilicon film;

[0030] Executing step S3: performing photolithography a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com