Stepped ultrasonic preparation of protein-polysaccharide emulsion and functional food application

A technology of emulsion and sodium caseinate, which is applied in the directions of emulsion transportation, food ultrasonic treatment, food ingredient function, etc. The effect of uniform particle size distribution and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] The preparation method of sodium caseinate-pectin complex, carries out according to the following steps:

[0119] (1) Sodium caseinate is dissolved in distilled water, and magnetically stirred until the protein is completely dissolved; a sodium caseinate solution with a concentration of 10 mg / mL is obtained;

[0120] (2) Dissolving the pectin in the aqueous solution, and magnetically stirring until completely dissolved; obtaining a pectin solution with a concentration of 10 mg / mL;

[0121] (3) Step (2) pectin solution is added dropwise in the step (1) sodium caseinate solution in a ratio of 1:1 by volume, so that the mass ratio of sodium caseinate and pectin is 5:5, and then Adjust the pH=4 of the mixed solution;

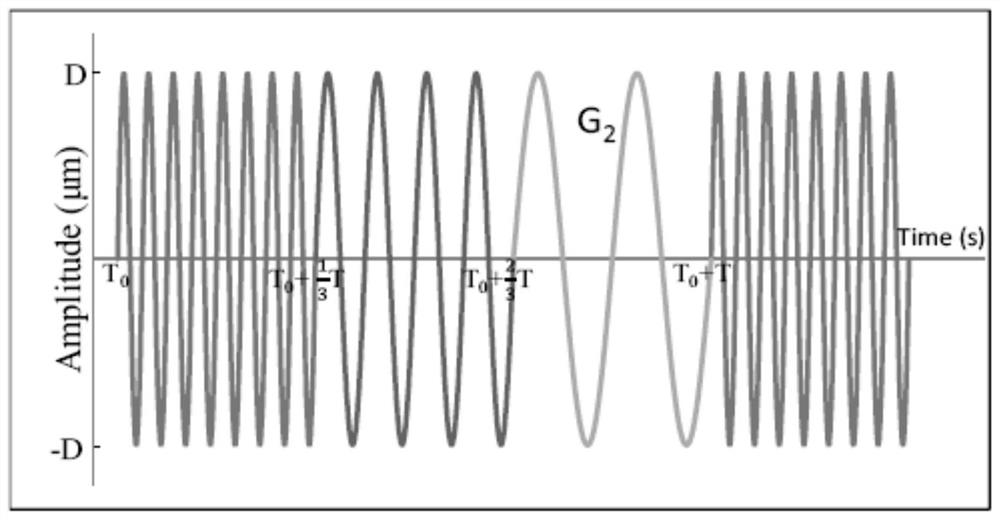

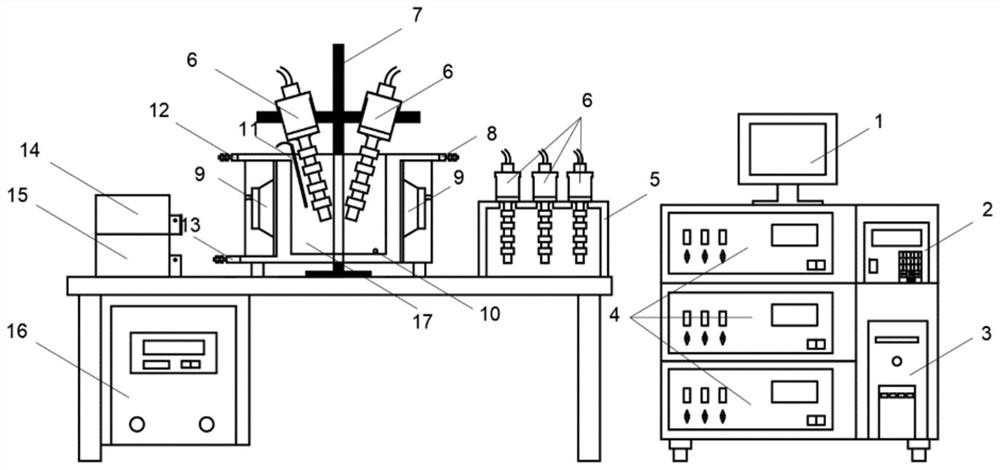

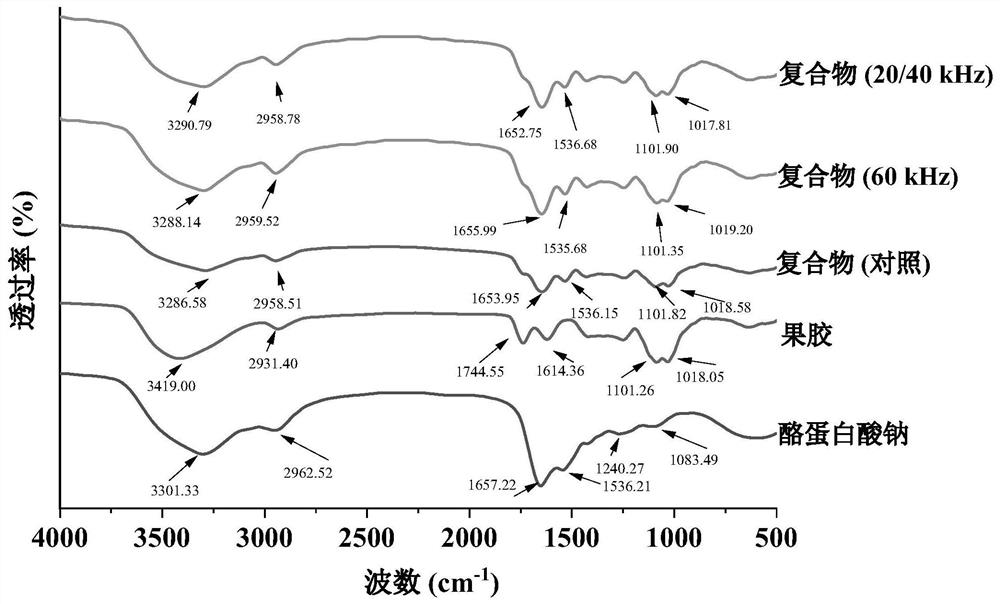

[0122] (4) Put the complex solution obtained in step (3) into a multi-mode flat-panel ultrasonic device for divergent ultrasonic treatment. The ultrasonic conditions are: single frequency 20kHz, 35kHz, 40kHz, 50kHz, 60kHz, dual frequency 20kHz / 35kHz , 20kHz...

Embodiment 2

[0133] The preparation method of sodium caseinate-pectin complex, carries out according to the following steps:

[0134] (1) Sodium caseinate is dissolved in distilled water, and magnetically stirred until the protein is completely dissolved; a sodium caseinate solution with a concentration of 10 mg / mL is obtained;

[0135] (2) Dissolving the pectin in the aqueous solution, and magnetically stirring until completely dissolved; obtaining a pectin solution with a concentration of 10 mg / mL;

[0136] (3) Step (2) pectin solution is added dropwise in the step (1) sodium caseinate solution in a ratio of 1:1 by volume, so that the mass ratio of sodium caseinate and pectin is 5:5, and then Adjust the pH=4 of the mixed solution;

[0137] (4) Put the complex solution obtained in step (3) into a multi-mode flat-panel ultrasonic device for divergent ultrasonic treatment. The ultrasonic conditions are: single frequency 60kHz, dual frequency 20 / 40kHz, and ultrasonic power density is 10W / L ...

Embodiment 3

[0149] The preparation method of sodium caseinate-pectin complex, carries out according to the following steps:

[0150] (1) Sodium caseinate is dissolved in distilled water, and magnetically stirred until the protein is completely dissolved; a sodium caseinate solution with a concentration of 10 mg / mL is obtained;

[0151] (2) Dissolving the pectin in the aqueous solution, and magnetically stirring until completely dissolved; obtaining a pectin solution with a concentration of 10 mg / mL;

[0152] (3) Step (2) pectin solution is added dropwise in the step (1) sodium caseinate solution in a ratio of 1:1 by volume, so that the mass ratio of sodium caseinate and pectin is 5:5, and then Adjust the pH=4 of the mixed solution;

[0153] (4) Put the complex solution obtained in step (3) into a multi-mode flat-panel ultrasonic device for divergent ultrasonic treatment. The ultrasonic conditions are: single frequency 60kHz 50W / L, dual frequency 20 / 40kHz 30W / L; Time: 5min, 10min, 15min, 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com