Scalpel for doctors in cardiac intensive care unit and production process of scalpel

A technology of intensive care unit and production technology, which is applied in the field of scalpels, can solve the problems of high production cost and high cost of use of scalpels, and achieve the effect of improving comprehensive use performance and reducing production and preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

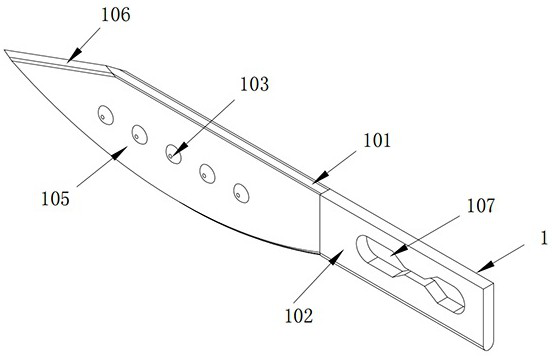

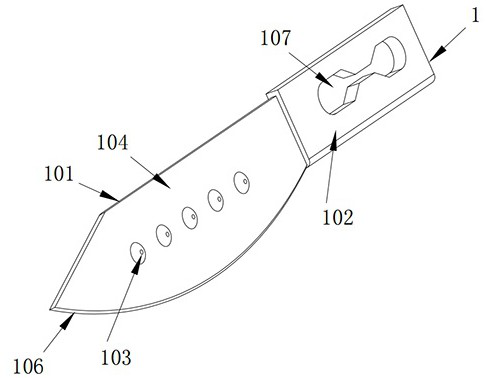

[0072] A production process of a scalpel for doctors in a cardiac intensive care unit, step 1, preparation of a scalpel base 1;

[0073] The preparation of scalpel base 1 in step 1 includes:

[0074] S1, raw material preparation, including the following raw material composition by weight,

[0075] 31 parts of zirconia;

[0076] 41 parts of alumina powder;

[0077] 9 parts of Lingkuite;

[0078] 6 parts of zinc oxide;

[0079] 5 parts of yttrium oxide;

[0080] Chitin 3 parts.

[0081] Furthermore, chitin, also known as chitin and chitin, is a polysaccharide extracted from the shells of marine crustaceans, and its chemical formula is (C8H13O5N)n. Chitin is light beige to white, soluble in concentrated hydrochloric acid, phosphoric acid, sulfuric acid and acetic acid, insoluble in alkali and other organic solvents, and insoluble in water. Chitosan, a deacetylated derivative of chitin, is insoluble in water but soluble in some dilute acids. By adding chitin to the raw mate...

Embodiment 2

[0102] A production process of a scalpel for doctors in a cardiac intensive care unit, step 1, preparation of a scalpel base 1;

[0103] The preparation of scalpel base 1 in step 1 includes:

[0104] S1, raw material preparation, including the following raw material composition by weight,

[0105] 33 parts of zirconia;

[0106] 42 parts of alumina powder;

[0107] 11 parts of Lingkuite;

[0108] 7 parts of zinc oxide;

[0109] 6 parts of yttrium oxide;

[0110] Chitin 4 parts.

[0111] Furthermore, chitin, also known as chitin and chitin, is a polysaccharide extracted from the shells of marine crustaceans, and its chemical formula is (C8H13O5N)n. Chitin is light beige to white, soluble in concentrated hydrochloric acid, phosphoric acid, sulfuric acid and acetic acid, insoluble in alkali and other organic solvents, and insoluble in water. Chitosan, a deacetylated derivative of chitin, is insoluble in water but soluble in some dilute acids. By adding chitin to the raw mater...

Embodiment 3

[0132] A production process of a scalpel for doctors in a cardiac intensive care unit, step 1, preparation of a scalpel base 1;

[0133] The preparation of scalpel base 1 in step 1 includes:

[0134] S1, raw material preparation, including the following raw material composition by weight,

[0135] 35 parts of zirconia;

[0136] 44 parts of alumina powder;

[0137] 13 parts of Lingkuite;

[0138] 8 parts of zinc oxide;

[0139] 7 parts of yttrium oxide;

[0140] Chitin 6 parts.

[0141] Furthermore, chitin, also known as chitin and chitin, is a polysaccharide extracted from the shells of marine crustaceans, and its chemical formula is (C8H13O5N)n. Chitin is light beige to white, soluble in concentrated hydrochloric acid, phosphoric acid, sulfuric acid and acetic acid, insoluble in alkali and other organic solvents, and insoluble in water. Chitosan, a deacetylated derivative of chitin, is insoluble in water but soluble in some dilute acids. By adding chitin to the raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com