Fiber bundle with self-adaptive human body heat management function and preparation method thereof

A fiber bundle and thermal management technology, applied in yarns, textiles and papermaking, etc., can solve the problems of water resistance, limited adjustment ability of phase change materials, and fiber performance degradation, to ensure mechanical properties and durability, self-adaptive adjustment and control. Significant advantages and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

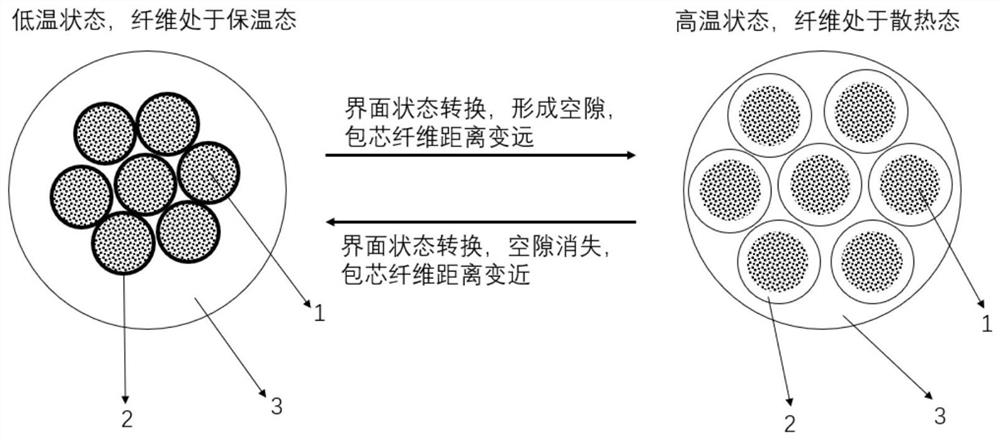

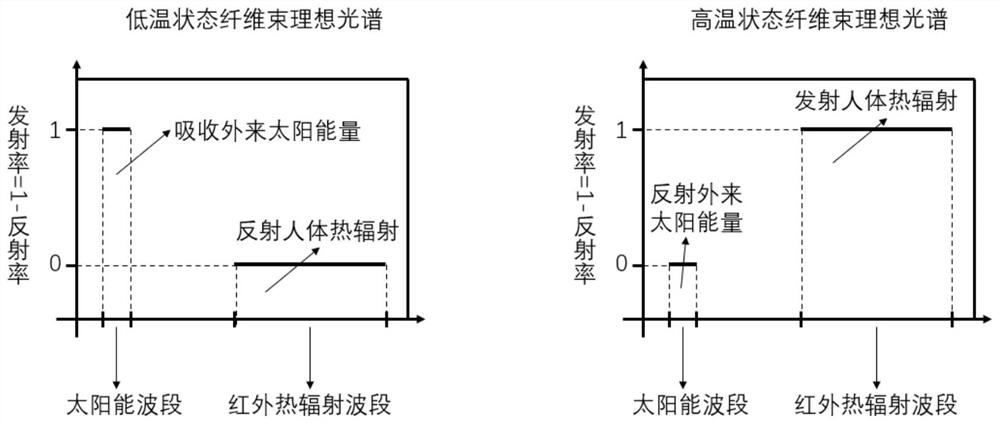

[0047] A fiber bundle with adaptive human body heat management function, the core-spun fiber 1 is made of alumina fiber with a diameter of 10 μm; the material of the core-spun interface 2 is ethanol with a thickness of 50nm; the bundle 3 is made of polyethylene, The thickness is 10 μm; the core-spun fibers 1 are combined in a parallel combination; after testing, when the ambient temperature is cycled between 10-40°C, the surface temperature of the dummy wrapped with fiber bundles is cycled between 18-30°C.

Embodiment 2

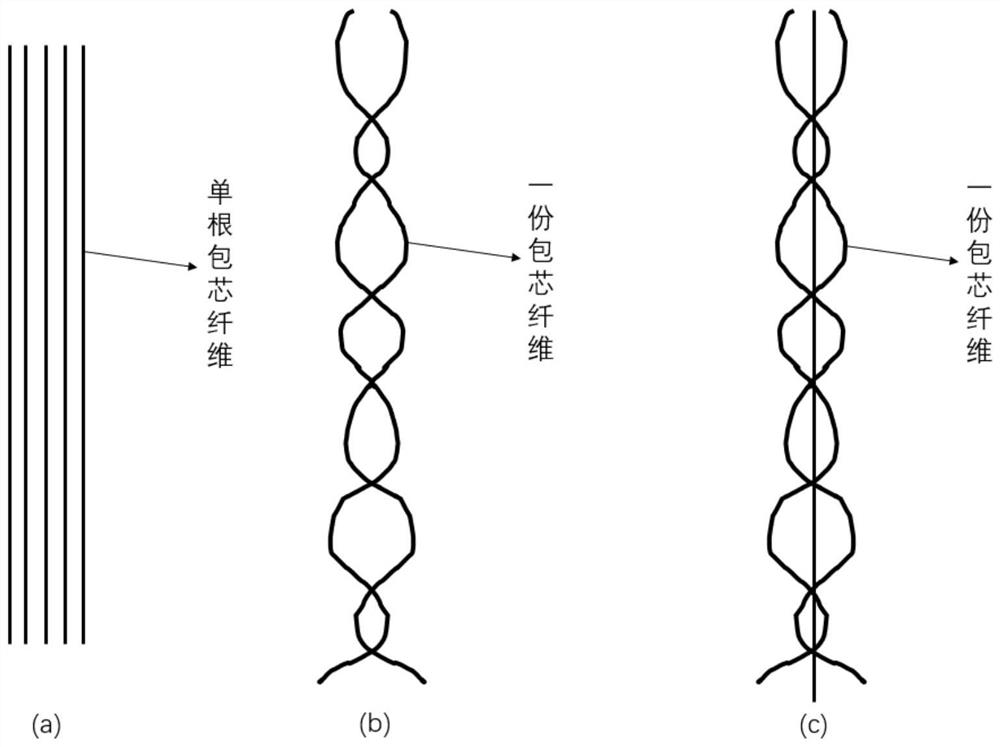

[0049] A fiber bundle with self-adaptive human body thermal management function, the material of the core-spun fiber 1 is quartz fiber with a diameter of 15 μm; the material of the core-spun interface 2 is acetone with a thickness of 100 nm; the material of the bundle package 3 is polymethacrylic acid Methyl ester with a thickness of 25 μm; the core-spun fiber 1 is combined in two spirals; after testing, when the ambient temperature is cycled between 10 and 40°C, the surface temperature of the dummy wrapped with fiber bundles is between 19°C and 28°C cycle.

Embodiment 3

[0051] A fiber bundle with self-adaptive human body thermal management function, the material of core-spun fiber 1 is high silica fiber with a diameter of 18 μm; the material of core-spun interface 2 is acetone with a thickness of 80nm; the material of bundle 3 is poly Vinyl fluoride with a thickness of 16 μm; the core-spun fiber 1 is combined by three parts of braiding; after testing, when the ambient temperature is cycled between 10 and 40 ° C, the surface temperature of the dummy wrapped with fiber bundles is between 16 and 33 ° C Cycle between.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com