Tail gas purification complete equipment matched with garbage negative pressure cracking incinerator

A tail gas purification and incinerator technology, which is applied in the direction of incinerators, lighting and heating equipment, and combustion methods, can solve the problems of affecting environmental sanitation, destroying production and living safety, wasting resources, etc., and achieves less toxic and harmful substances and energy utilization. The effect of various forms, simple equipment and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

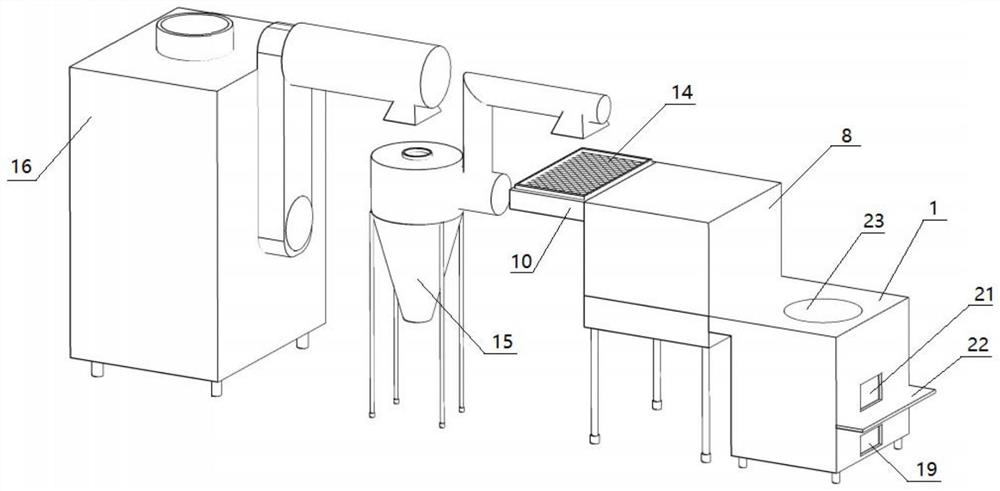

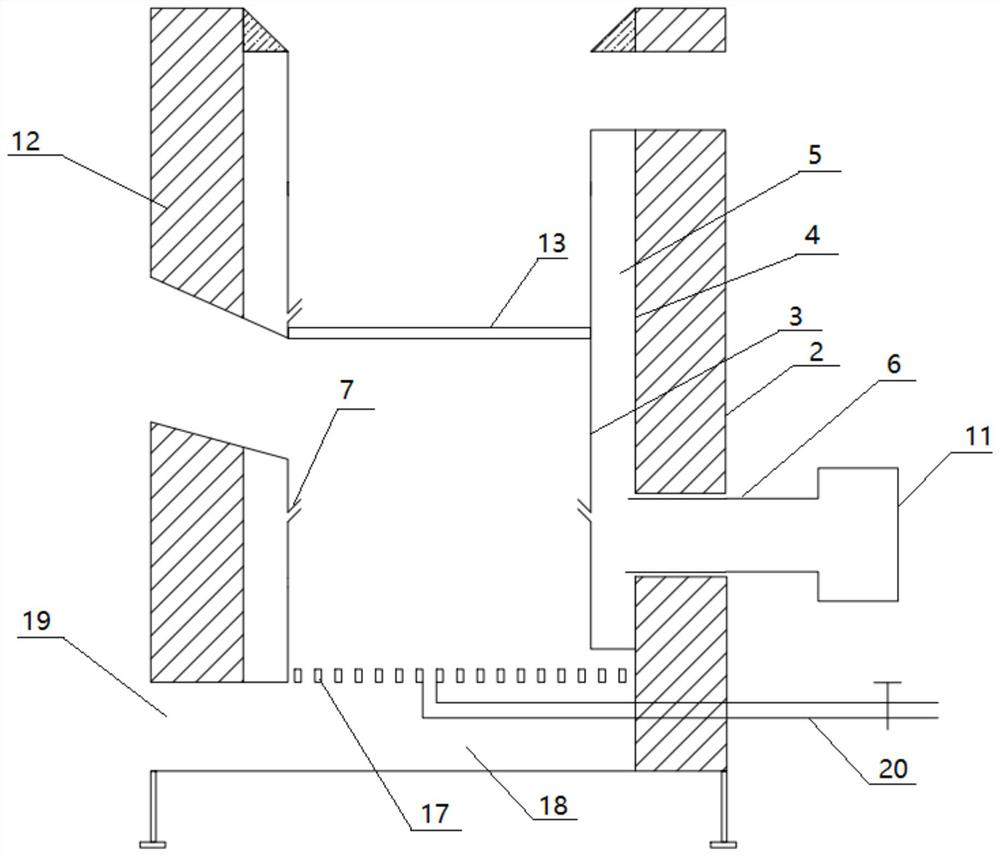

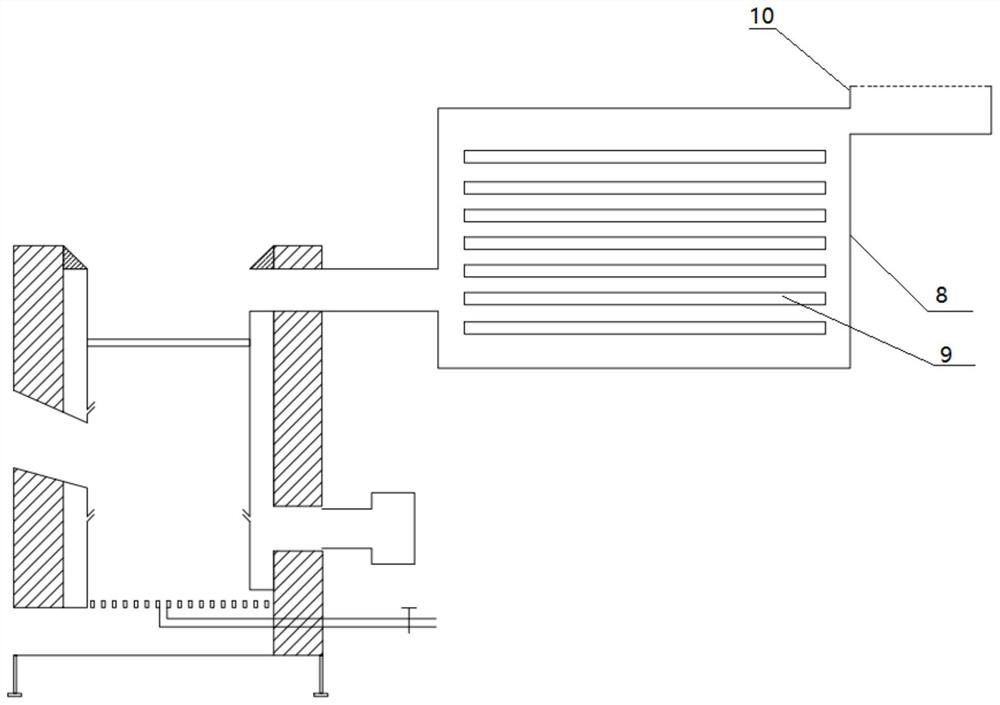

[0029] A complete set of tail gas purification equipment for a garbage negative pressure cracking incinerator, such as Figure 1-4 As shown, the incinerator 1 is included, and the incinerator 1 includes the outermost furnace wall layer 2, the innermost stove core 3 and the gas distribution layer 4 between the furnace wall layer 2 and the stove core 3, and the bottom of the stove core 3 is provided with Furnace bridge 17, the bottom of furnace bridge 17 is provided with ash storage box 18, and one side of ash storage box 18 is provided with ash outlet 19, and the bottom of stove core 3 is connected with gas pipe 20, provides combustion-supporting for the burning of rubbish. By adding gas combustion, it can also solve the problem that garbage with high moisture content cannot be directly processed. The stove core 3 is in a cylindrical structure and is made of high temperature and corrosion resistant materials. The pyrolysis and incineration of garbage is carried out in the stove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com