Device and method for compensating thermal distortion of DPL laser by using hologram generated by SLM

A laser and thermal distortion technology, applied in the field of lasers, can solve problems such as low convergence speed, limited precision, and long response time, and achieve the effects of improving beam quality, reducing costs, and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

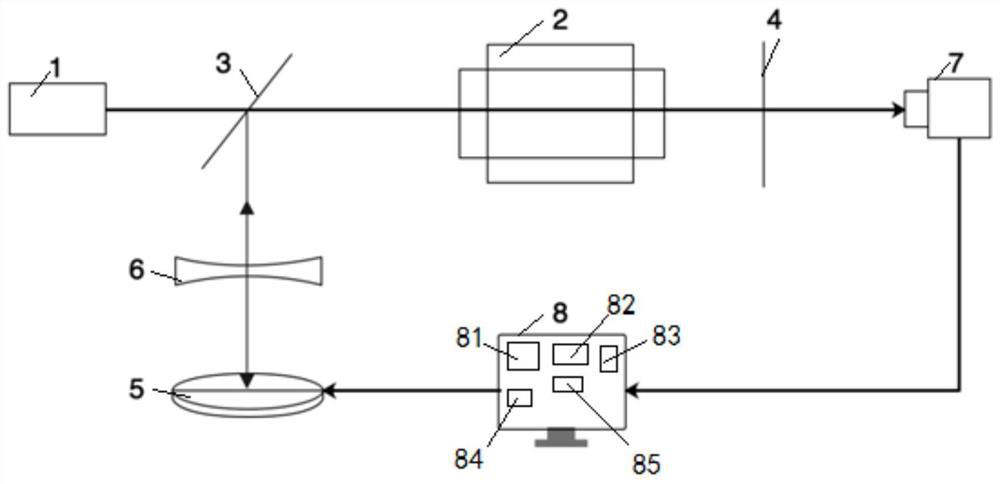

[0024] Please refer to figure 1 , the embodiment of the present invention provides a kind of device that utilizes SLM to produce hologram compensation DPL laser thermal distortion, comprises: laser diode 1, laser 2, high reflection mirror 3, output coupler 4, spatial light modulator (SLM) 5 , beam expander 6, CCD detector 7 and processing device 8.

[0025] The laser diode 1 is used to output the reference light, the laser 2 is used to output the laser light, the high reflective mirror 3 is located between the laser diode 1 and the laser 2, the beam expander 6 is located in the light emitting direction of the high reflective mirror 3, and the spatial light modulator 5 is located In the light-emitting direction of the beam expander 6, the CCD detector 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com