Method for reducing viscosity of silica sol with high solid content

A technology with high solid content and silica sol, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., and can solve problems such as reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

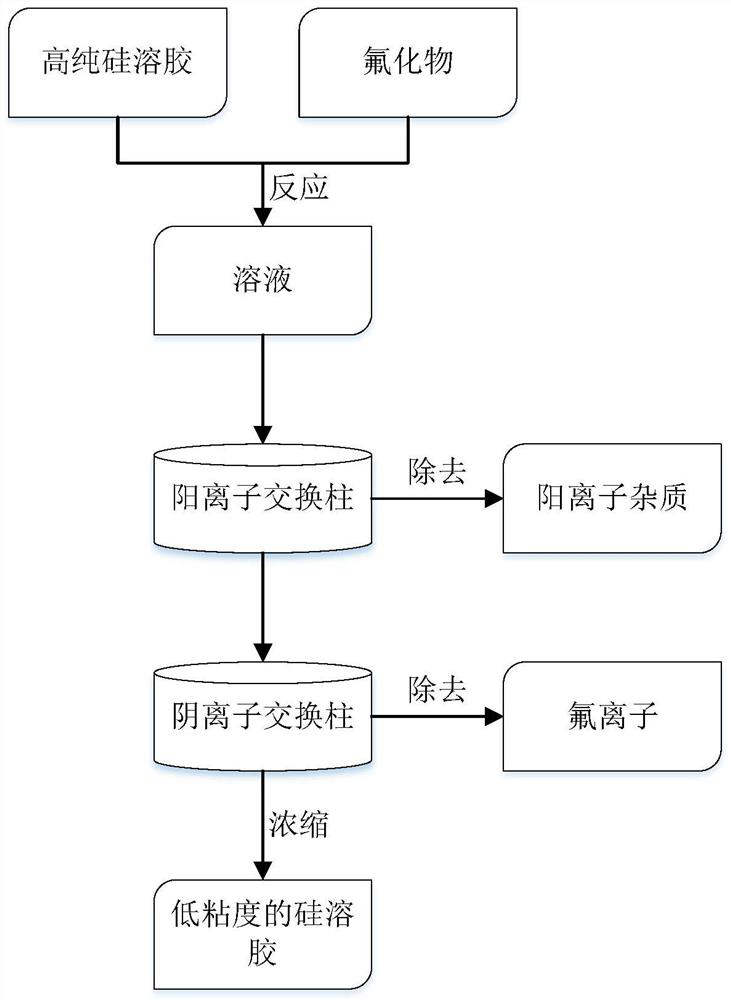

Method used

Image

Examples

Embodiment 1

[0022] Prepare 1 kg of high-purity silica sol (containing SiO 2 7.5%, pH 9.7), 5 g of sodium fluoride powder was added thereto, and then heated to 60° C. and kept for 10 minutes. After the solution was cooled, it passed through a cation exchange column and an anion exchange column successively, and the obtained semi-product was concentrated by ultrafiltration to a specific gravity of 1.315 to obtain a finished product. The characterization results are shown in Table 1.

Embodiment 2

[0024] Prepare 10kg of high-purity silica sol (containing SiO 2 19.0%, pH 8.0), 50 g of tetra-n-butylammonium fluoride (TBAF) crystals were added thereto, and then heated to 30° C. and kept for 60 minutes. After the solution was cooled, it passed through a cation exchange column and an anion exchange column successively, and the obtained semi-product was concentrated by ultrafiltration to a specific gravity of 1.374 to obtain a finished product. The characterization results are shown in Table 1.

Embodiment 3

[0026] Prepare 3kg of high-purity silica sol (containing SiO 2 19.0%, pH 9.0), 15 g of ammonium fluoride powder was added thereto, and then heated to 40° C. and kept for 30 minutes. After the solution was cooled, it passed through a cation exchange column and an anion exchange column successively, and the obtained semi-finished product was concentrated by ultrafiltration to a specific gravity of 1.265 to obtain a finished product. The characterization results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com