Slag former and application method thereof in refining high-purity chromium 15 high-chromium cast iron material

A technology of slagging agent and chromium cast iron, which is applied in the field of refining chromium cast iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

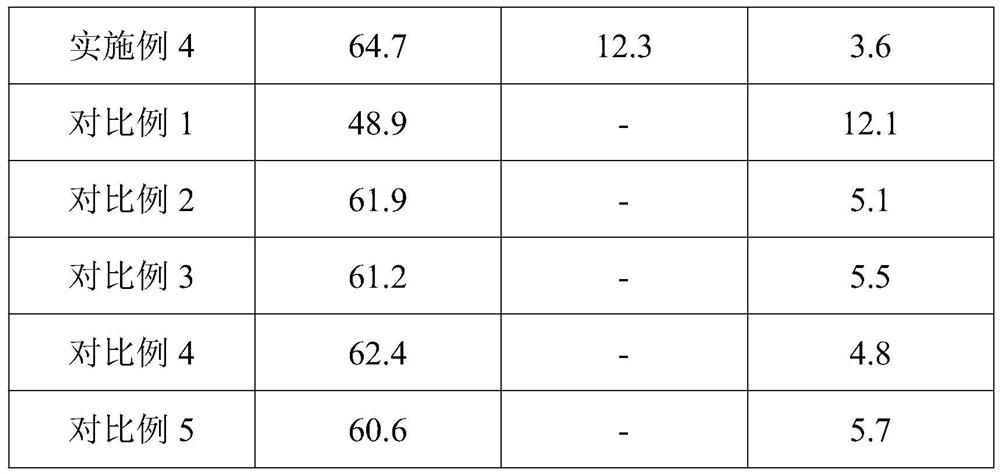

Examples

Embodiment 1

[0037] A kind of slagging agent, in weight part, comprises following raw material: 21 parts of palygorskite powder, 5 parts of fluorspar powder, 16 parts of talc powder, 7 parts of bentonite powder, 8 parts of magnesium carbonate powder, 3 parts of quartz powder, wheat rice 5 parts of stone powder, 8 parts of mineral wool, 3 parts of adhesive, 42 parts of water;

[0038] The quality index of described palygorskite powder is: SiO 2 : 53.06%; MgO: 24.78%; particle size is 800 mesh;

[0039] The quality index of described fluorspar powder is: CaF 2: 75.36%; particle size is 700 mesh;

[0040] The quality index of described talcum powder is: SiO 2 : 58.05%; MgO: 29.17%; particle size is 1000 mesh;

[0041] The quality index of described bentonite powder is: SiO 2 : 58.02%; Al 2 o 3 : 17.85%; particle size is 900 mesh;

[0042] The particle size of described magnesium carbonate powder is 800 orders;

[0043] The particle size of described quartz powder is 1000 orders;

[...

Embodiment 2

[0053] A kind of slagging agent, in weight part, comprises the following raw materials: 26 parts of palygorskite powder, 7 parts of fluorspar powder, 18 parts of talc powder, 8 parts of bentonite powder, 10 parts of magnesium carbonate powder, 5 parts of quartz powder, wheat rice 7 parts of stone powder, 10 parts of mineral wool, 3.6 parts of adhesive, 47 parts of water;

[0054] The quality index of described palygorskite powder is: SiO 2 : 54.21%; MgO: 26.08%; particle size is 900 mesh;

[0055] The quality index of described fluorspar powder is: CaF 2 : 76.35%; particle size is 700 mesh;

[0056] The quality index of described talcum powder is: SiO 2 : 58.67%; MgO: 29.16%; particle size is 1100 mesh;

[0057] The quality index of described bentonite powder is: SiO 2 : 60.28%; Al 2 o 3 : 20.64%; particle size is -900 mesh;

[0058] The particle size of described magnesium carbonate powder is 900 orders;

[0059] The particle size of described quartz powder is 1000 o...

Embodiment 3

[0069] A kind of slagging agent, in weight part, comprises following raw material: 29 parts of palygorskite powder, 8 parts of fluorspar powder, 18 parts of talcum powder, 10 parts of bentonite powder, 11 parts of magnesium carbonate powder, 5 parts of quartz powder, wheat rice 9 parts of stone powder, 12 parts of mineral wool, 4 parts of adhesive, 52 parts of water;

[0070] The quality index of described palygorskite powder is: SiO 2 : 55.03%; MgO: 26.92%; particle size is 800 mesh;

[0071] The quality index of described fluorspar powder is: CaF 2 : 76.01%; particle size is 800 mesh;

[0072] The quality index of described talcum powder is: SiO 2 : 60.18%; MgO: 31.52%; particle size is 1100 mesh;

[0073] The quality index of described bentonite powder is: SiO 2 : 63.58%; Al 2 o 3 : 22.01%; particle size is 900 mesh;

[0074] The particle size of described magnesium carbonate powder is 800 orders;

[0075] The particle size of described quartz powder is 1000 orders...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com