Preparation method and application of perovskite solar cell with copper phthalocyanine carbon dots as hole transport layer

A technology of hole transport layer and solar cell, which is applied in the field of solar cell materials, can solve the problems of high cost of hole transport layer, internal quality affecting PSC long-term operation and thermal stability, etc., to reduce manufacturing cost, improve optical performance and The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

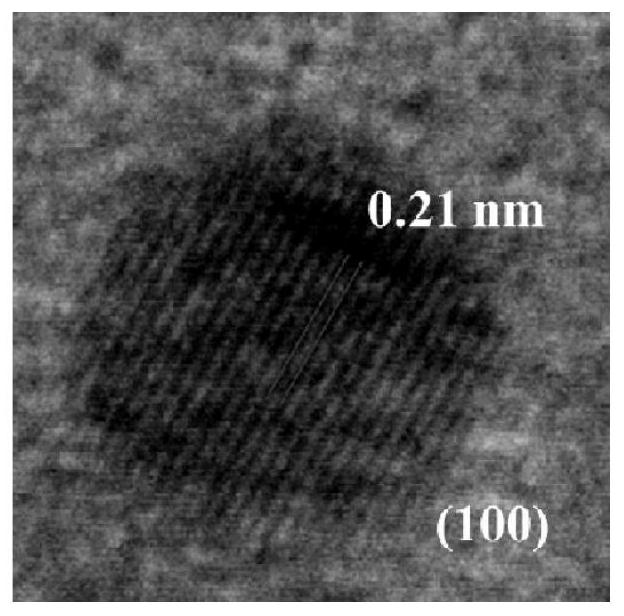

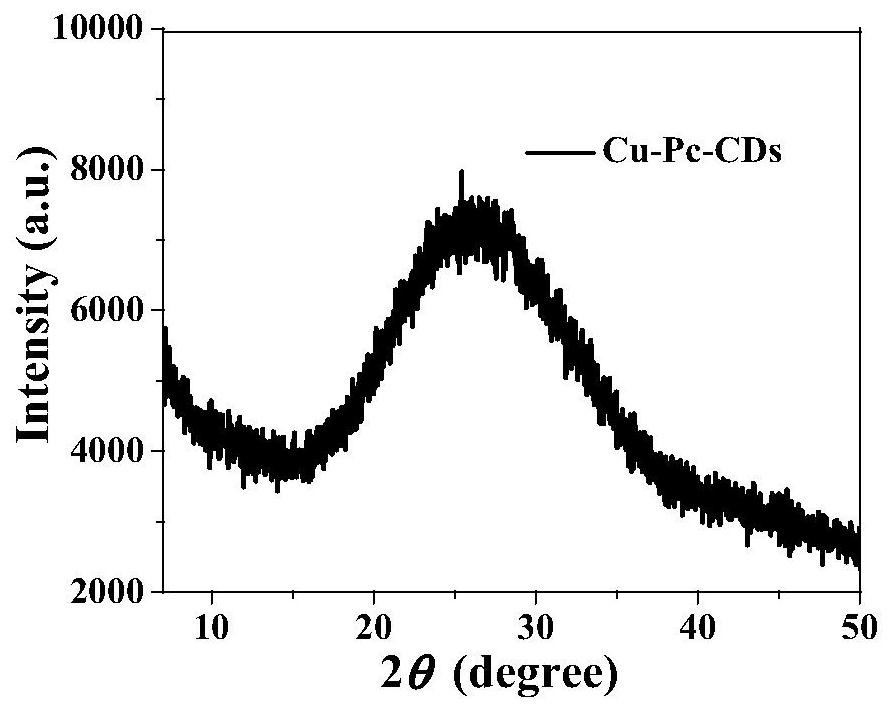

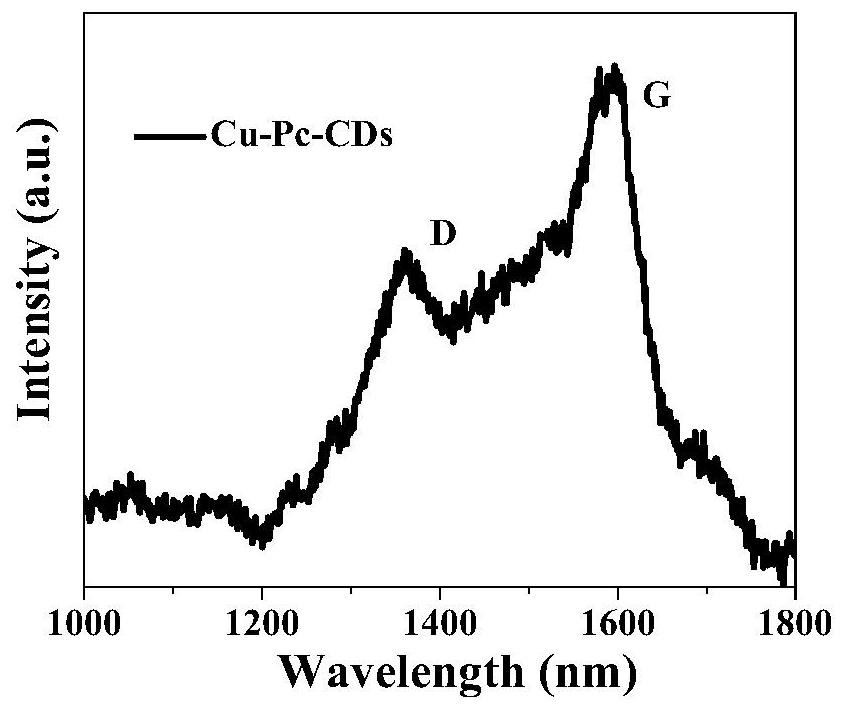

Image

Examples

Embodiment 1

[0023] (1) Transparent conductive substrate: the substrate is selected from FTO conductive glass, and the FTO glass substrate is ultrasonically cleaned in detergent, deionized water, isopropanol and absolute ethanol for 15 minutes;

[0024] (2) Electron transport layer: One end of the clean FTO glass sheet is blank as the negative electrode; the rest is first coated with 0.4M titanium tetraisopropoxide ethanol solution to block TiO 2 layer, spin-coated at 1000rpm for 3s, then spin-coated at 2500rpm for 30s, and then heated at 125°C for 5min; then spin-coated mesoporous TiO 2 ethanol dispersion (TiO 2 Mass ratio with ethanol 1:3.5), spin coating at 1000rpm for 3s, then spin coating at 3500rpm for 30s, and finally sintering at 500°C for 30min;

[0025] (3) Perovskite absorbing layer: 0.461g PbI 2 and 0.159g MAI were dissolved in 0.72mL DMF and 0.072mL DMSO to prepare a perovskite precursor solution, then spin-coated at 1000rpm for 10s, and then 200μL of chlorobenzene was added...

Embodiment 2

[0036] (1) Transparent conductive substrate: the substrate is selected from FTO conductive glass, and the FTO glass substrate is ultrasonically cleaned in detergent, deionized water, isopropanol and absolute ethanol for 15 minutes;

[0037] (2) Electron transport layer: One end of the clean FTO glass sheet is blank as the negative electrode; the rest is first coated with 0.4M titanium tetraisopropoxide ethanol solution to block TiO 2 layer, spin-coated at 1000rpm for 3s, then spin-coated at 2500rpm for 30s, and then heated at 125°C for 5min; then spin-coated mesoporous TiO 2 ethanol dispersion (TiO 2 Mass ratio with ethanol 1:3.5), spin coating at 1000rpm for 3s, then spin coating at 3500rpm for 30s, and finally sintering at 500°C for 30min;

[0038] (3) Perovskite absorbing layer: 0.461g PbI 2 and 0.159g MAI were dissolved in 0.72mL DMF and 0.072mL DMSO to prepare a perovskite precursor solution, then spin-coated at 1000rpm for 10s, and then 200μL of chlorobenzene was added...

Embodiment 3

[0044] (1) Transparent conductive substrate: the substrate is selected from FTO conductive glass, and the FTO glass substrate is ultrasonically cleaned in detergent, deionized water, isopropanol and absolute ethanol for 15 minutes;

[0045] (2) Electron transport layer: One end of the clean FTO glass sheet is blank as the negative electrode; the rest is first coated with 0.4M titanium tetraisopropoxide ethanol solution to block TiO 2 layer, spin-coated at 1000rpm for 3s, then spin-coated at 2500rpm for 30s, and then heated at 125°C for 5min; then spin-coated mesoporous TiO 2 ethanol dispersion (TiO 2 Mass ratio with ethanol 1:3.5), spin coating at 1000rpm for 3s, then spin coating at 3500rpm for 30s, and finally sintering at 500°C for 30min;

[0046] (3) Perovskite absorbing layer: 0.461g PbI 2 and 0.159g MAI were dissolved in 0.72mL DMF and 0.072mL DMSO to prepare a perovskite precursor solution, then spin-coated at 1000rpm for 10s, and then 200μL of chlorobenzene was added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com