Method for improving product quality by reshaping microbial composition in production process of stinky tofu

A technology of stinky tofu and quality, applied in the field of food processing, can solve the problems of easy to produce savory taste, limited development, long storage time, etc., to solve the influence of morphological structure, taste and flavor, optimize taste and flavor, and reduce air content. effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

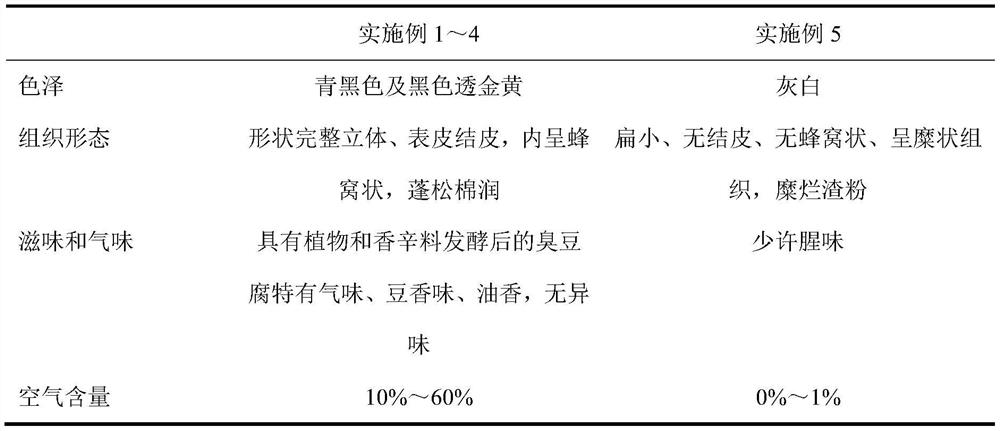

Examples

Embodiment 1

[0029] Stinky tofu production method, the steps are as follows:

[0030] (1) marinated

[0031] The fermented liquid is inflated with carbon dioxide gas before use, and the dissolved oxygen content of the fermented liquid is controlled within 0.03mg / L. The tofu is subjected to microaerobic fermentation in the fermented liquid at a fermentation temperature of 20°C for 1 hour to obtain fermented stinky tofu. After the fermentation, the abundance of Lactobacillus in the fermentation broth is 30%, the abundance of Bacillus subtilis is 15%, and the total organic acid content produced by fermentation is 150mg / kg;

[0032] (2) Packaging

[0033] Fry the fermented stinky tofu, pack the fried stinky tofu, use a deoxidizer to deoxidize or other non-oxygen gas perfusion in the packaging container to control the oxygen content to 3%, and place it at 20°C for 1 hour after packaging , measure the total organic acid content that fermentation produces at this moment and keep not less than 1...

Embodiment 2

[0038] Stinky tofu production method, the steps are as follows:

[0039] (1) marinated

[0040] The fermented liquid is inflated with nitrogen gas before use, and the dissolved oxygen in the fermented liquid is controlled within 0.02mg / L. The tofu is subjected to microaerobic fermentation in the fermented liquid at a temperature of 30°C for 8 hours. The abundance of Bacillus is 20%, the abundance of Bacillus subtilis is 10%, and the total organic acid content produced by fermentation is 100mg / kg;

[0041] (2) Packaging

[0042] Fry the fermented stinky tofu, pack the fried stinky tofu, use a deoxidizer to deoxidize or other non-oxygen gas perfusion in the packaging container to deoxidize to an oxygen content of 2%, and place it at 30°C for 2 hours after packaging. The total organic acid content produced by fermentation is not less than 100mg / kg;

[0043] (3) Sterilization

[0044] The finished stinky tofu is perfused and packaged with a deoxidizer or other non-oxygen gas, ...

Embodiment 3

[0047] Stinky tofu production method, the steps are as follows:

[0048] (1) marinated

[0049] The fermented liquid is aerated with nitrogen gas before use, and the dissolved oxygen in the fermented liquid is controlled within 0.01mg / L. The tofu is subjected to microaerobic fermentation in the fermented liquid. The fermentation temperature is 40°C for 6 hours. After the fermentation is completed, the The abundance of Lactobacillus is 35%, the abundance of Bacillus subtilis is 10%, and the total organic acid content produced by fermentation is 120mg / kg;

[0050] (2) Packaging

[0051] The fried stinky tofu is packaged, and the packaging container is deoxidized by deoxidizing or other non-oxygen gas perfusion until the oxygen content is 0.5%. After packaging, it is placed at 30°C for 2 hours, and the total organic acid content produced by fermentation remains constant. Less than 120mg / kg;

[0052] (3) Sterilization

[0053] The finished stinky tofu is perfused and packaged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com