Wooden decorative plate and industrial manufacturing method

A decorative board and wood technology, applied in the field of board manufacturing, can solve problems such as difficult to repair, unsightly, easy to absorb moisture, etc., and achieve the effects of enriching the visual effect of annual rings, reducing the degree of imbalance, and not easily deforming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

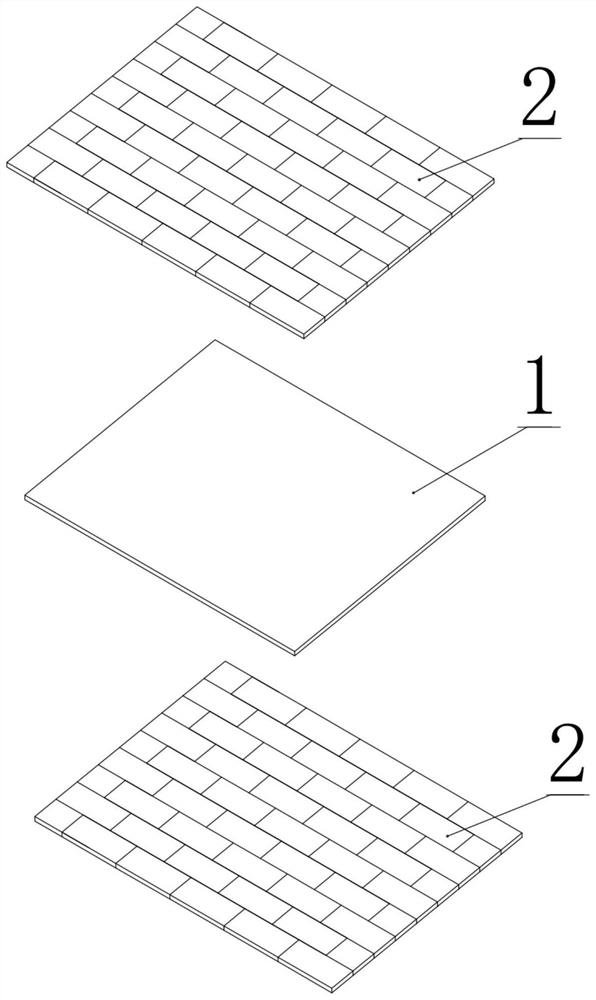

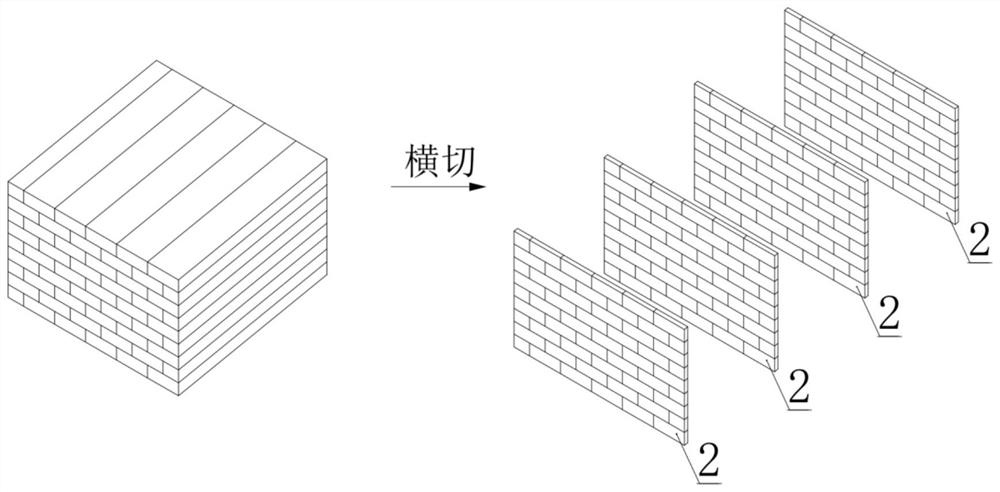

[0039] A wooden decorative board, including a lining material 1 and a panel 2, and the panels 2 are glued on both sides of the lining material 1, such as figure 1 shown. Panel 2 is fabricated as figure 2 and 8 As shown, the panel 2 is spliced by a plurality of wood chips of equal thickness, and the surface parallel to the lining material 1 of each wood chip is the cross-section of the wood.

[0040] In this embodiment, each piece of wood in the panel 2 is rectangular, and each piece of wood is spliced into the panel 2 in a staggered arrangement.

[0041] In this embodiment, the lining material 1 is an aluminum plate.

[0042] The industrialized manufacturing method of wooden decorative board in the present embodiment comprises the following steps:

[0043] Step 1: Slicing and cutting the plank on all sides;

[0044] Step 2: Pre-assemble the four-sided sliced planks, and keep the extension direction of the tree fibers in each plank and squares consistent; according ...

Embodiment 2

[0049] A wooden decorative board, including a lining material 1 and a panel 2, and the panels 2 are glued on both sides of the lining material 1, such as figure 1 shown. Panel 2 is fabricated as figure 2 and 8 As shown, the panel 2 is spliced by a plurality of wood chips of equal thickness, and the surface parallel to the lining material 1 of each wood chip is the cross-section of the wood.

[0050] In this embodiment, each piece of wood in the panel 2 is rectangular, and each piece of wood is spliced into the panel 2 in a staggered arrangement.

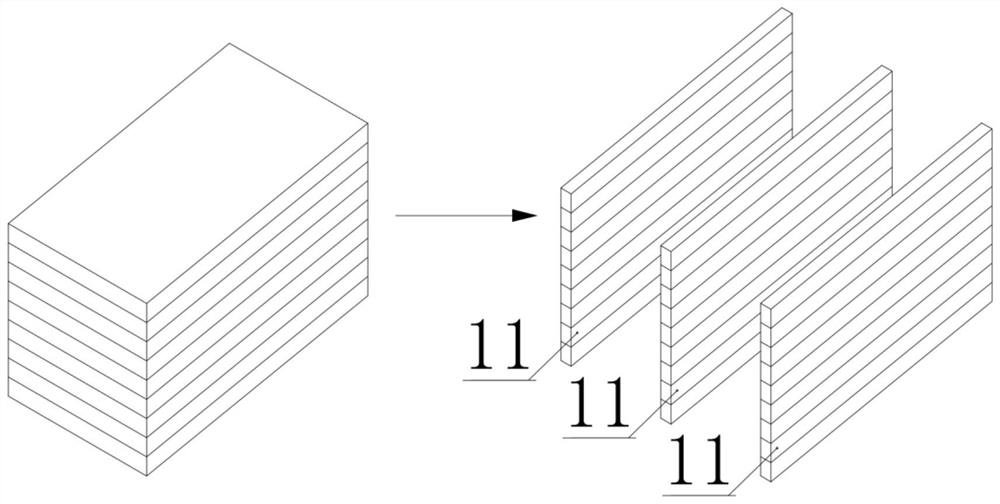

[0051] In this embodiment, the lining material 1 only includes a layer of wooden boards 11 , and two sides of the wooden boards 11 are glued with a layer of panels 2 . Wherein, the wooden plank 11 is assembled horizontally by multiple pieces of planed wood with equal thickness. image 3 shown.

[0052] The industrialized manufacturing method of wooden decorative board in the present embodiment comprises the following steps:...

Embodiment 3

[0058] A wooden decorative board, including a lining material 1 and a panel 2, and the panels 2 are glued on both sides of the lining material 1, such as figure 1 shown. Panel 2 is fabricated as figure 2 and 8 As shown, the panel 2 is spliced by a plurality of wood chips of equal thickness, and the surface parallel to the lining material 1 of each wood chip is the cross-section of the wood.

[0059] In this embodiment, each piece of wood in the panel 2 is rectangular, and each piece of wood is spliced into the panel 2 in a staggered arrangement.

[0060] In this embodiment, the lining material 1 includes a layer of wooden board 11 and glass fiber mesh 12 glued on both sides of the wooden board 11, such as Figure 4 As shown; the two sides of the lining material 1 are respectively bonded with a layer of panels 2 with adhesive. Wherein, the wooden plank 11 is assembled horizontally by multiple pieces of planed wood with equal thickness. image 3 shown.

[0061] In thi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap