Method for preparing 2,5-furandiformaldoxime

A technology of furandicarbaldehyde oxime and furandicarbaldehyde, which is applied in the field of green chemistry, can solve problems that have not been reported, and achieve the effects of improving catalytic efficiency, low production cost, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

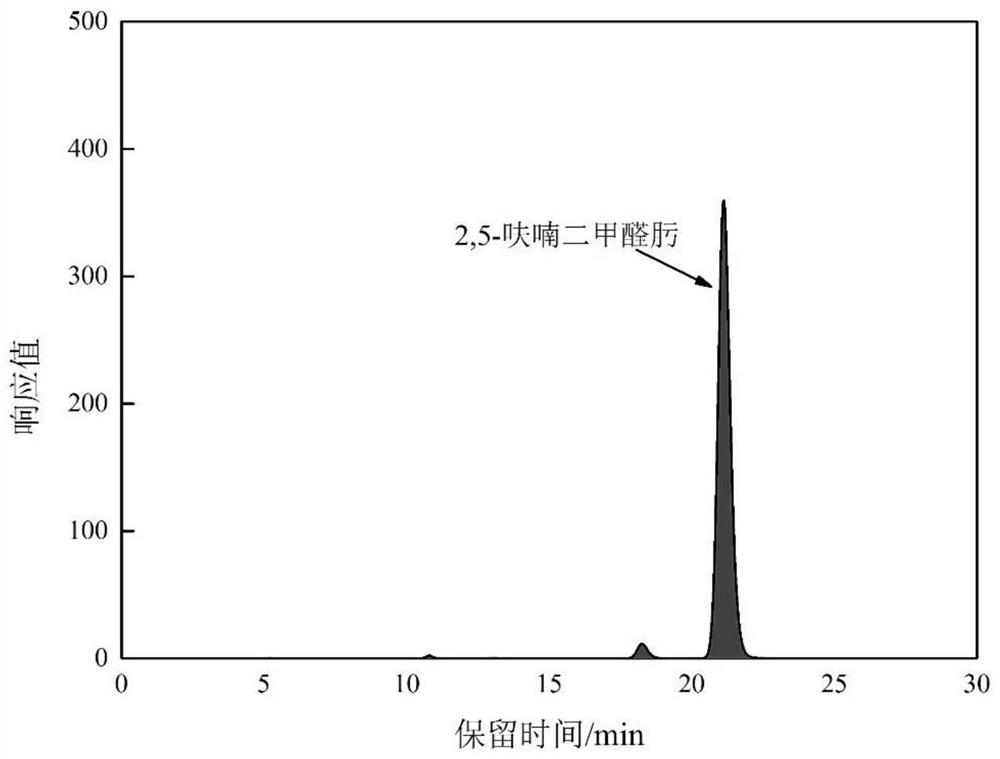

[0120] Mix 20mmol of 2,5-furandicarbaldehyde, 105mmol of butanone oxime, and 5g of methanol evenly for 10h -1 The speed is continuously injected into the continuous loop reactor, the catalyst is ferric sulfate (filling amount is 0.25g), the reaction temperature is 60°C, and the reaction time is 4h to obtain 2,5-furandimaldehyde oxime solution, which is quantified by HPLC Analysis, the high performance liquid phase chromatogram of the product 2,5-furandicarbaldehyde oxime that embodiment 1 prepares is as follows figure 1 As shown, the conversion rate of 2,5-furandicarbaldehyde is 100%, the selectivity of 2,5-furandicarbaldehyde oxime is 99.6%, and the purity is 99.4%.

Embodiment 2

[0122] Mix 30mmol of 2,5-furandicarbaldehyde, 65mmol of cyclohexanone oxime, and 360g of N,N-dimethylformamide evenly, with 20h -1 The speed is continuously injected into the continuous loop reactor, and the catalyst is zirconium phosphate (Zr(HPO 4 ) 2 ) (filling amount is 0.15g), the reaction temperature is 150°C, and the reaction time is 1min to obtain 2,5-furandicarbaldehyde oxime solution, quantitatively analyzed by HPLC, the conversion rate of 2,5-furandicarbaldehyde is 100%, The selectivity of 2,5-furandicarbaldehyde oxime was 99.7%, and the purity was 99.1%.

Embodiment 3

[0124] Mix 80mmol of 2,5-furandicarbaldehyde, 800mmol of acetone oxime, and 200g of tetrahydrofuran evenly for 0.5h -1 The speed is continuously injected into the continuous loop reactor, the catalyst is NKF-6(β) molecular sieve (filling amount is 2.5g), the reaction temperature is 30°C, and the reaction time is 5h to obtain 2,5-furandicarbaldehyde oxime The solution was quantitatively analyzed by HPLC, and the conversion rate of 2,5-furandicarbaldehyde was 100%, the selectivity of 2,5-furandicarbaldehyde oxime was 99.2%, and the purity was 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com