A kind of high fluorine-containing C9 resin hydrogenation catalyst and its preparation method and application

A hydrogenation catalyst and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as complex process flow and low defluorination accuracy, achieve high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

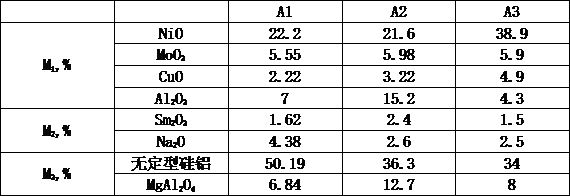

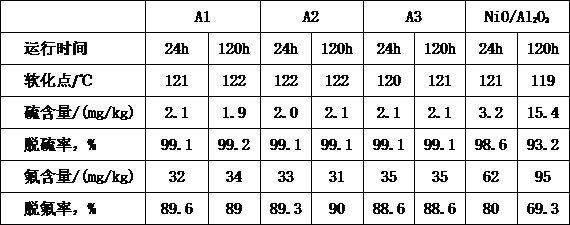

Embodiment 1

[0026] Add 86.1g of nickel nitrate, 3.8g of copper chloride and 23.5g of aluminum sulfate into water to prepare solution I, then add 0.5mol / L sodium hydroxide solution dropwise into solution I, control the reaction temperature to 65°C, and the pH of the system to be 9 , After the precipitation is completed, continue to stir at constant temperature for 4 hours, and the obtained slurry is set aside. Dissolve 6.9g of ammonium heptamolybdate in water, add 2g of sodium dodecylsulfonate to prepare solution II, stir and heat to 80°C, then add the slurry obtained above into solution II, and reflux at 120°C for 4h. The obtained product is filtered, washed, and dried to obtain component M 1 precursors.

[0027] 24g sodium metaaluminate, 100g sodium silicate (25% SiO 2 content), 33.5g of aluminum sulfate were made into solutions, and flowed into the reaction vessel, keeping the reaction temperature at 35°C, pH value at 6.5, reacting for 0.5 h, then heating to 60°C, aging for 3h to obtain...

Embodiment 2

[0030] Add 37.3g of nickel chloride, 6.7g of copper nitrate and 111.8g of aluminum nitrate into water to prepare solution I, then add 0.6mol / L ammonia solution dropwise into solution I, control the reaction temperature to 50°C, the pH of the system to 10, and precipitate After completion, continue to stir at constant temperature for 3 h, and the obtained slurry is set aside. Dissolve 7.3g of ammonium heptamolybdate in water, and add 2.5g of hexadecyltrimethylammonium bromide to prepare solution II, stir and heat to 50°C, then add the slurry obtained above into solution II, at 80°C Reflux reaction for 3h, the obtained product was filtered, washed and dried to obtain component M 1 precursors.

[0031] 32.2g sodium metaaluminate, 40g sodium silicate (25%SiO 2 Content), 67g of aluminum sulfate were made into solutions, and flowed into the reaction vessel, keeping the reaction temperature at 20 ° C, pH value of 9.5, reacted for 1.5 h, then heated to 75 ° C, aged for 0.5 h to obta...

Embodiment 3

[0034] Add 151g of nickel nitrate, 14.8g of copper nitrate and 31.6g of aluminum nitrate into water to prepare solution Ⅰ, then add 0.5mol / L sodium hydroxide solution dropwise into solution Ⅰ, control the reaction temperature to 80°C, the system pH to 9, and precipitate After completion, continue stirring at constant temperature for 5 h, and the obtained slurry is set aside. Dissolve 6.8g of ammonium tetramolybdate in water, add 2g of sodium dodecylsulfonate to prepare solution II, stir and heat to 65°C, then add the slurry obtained above into solution II, and reflux at 100°C for 5h, The obtained product is filtered, washed, and dried to obtain component M 1 precursors.

[0035] 16g sodium metaaluminate, 40g sodium silicate (25% SiO 2 content), 47g of aluminum sulfate were made into solutions, and flowed into the reaction vessel, keeping the reaction temperature at 50°C, the pH value was 8, reacted for 2.5 hours, then heated to 90°C, and aged for 1.5h to obtain amorphous sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com