Pollutant control process for treating hazardous wastes by using steelmaking converter

A technology for steel-making converters and hazardous wastes, which is applied in the field of pollutant control technology for steel-making converters to treat hazardous wastes, can solve problems such as excessive combustion value, industrial production impact, resource loss, etc. The effect of preventing the consumption of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

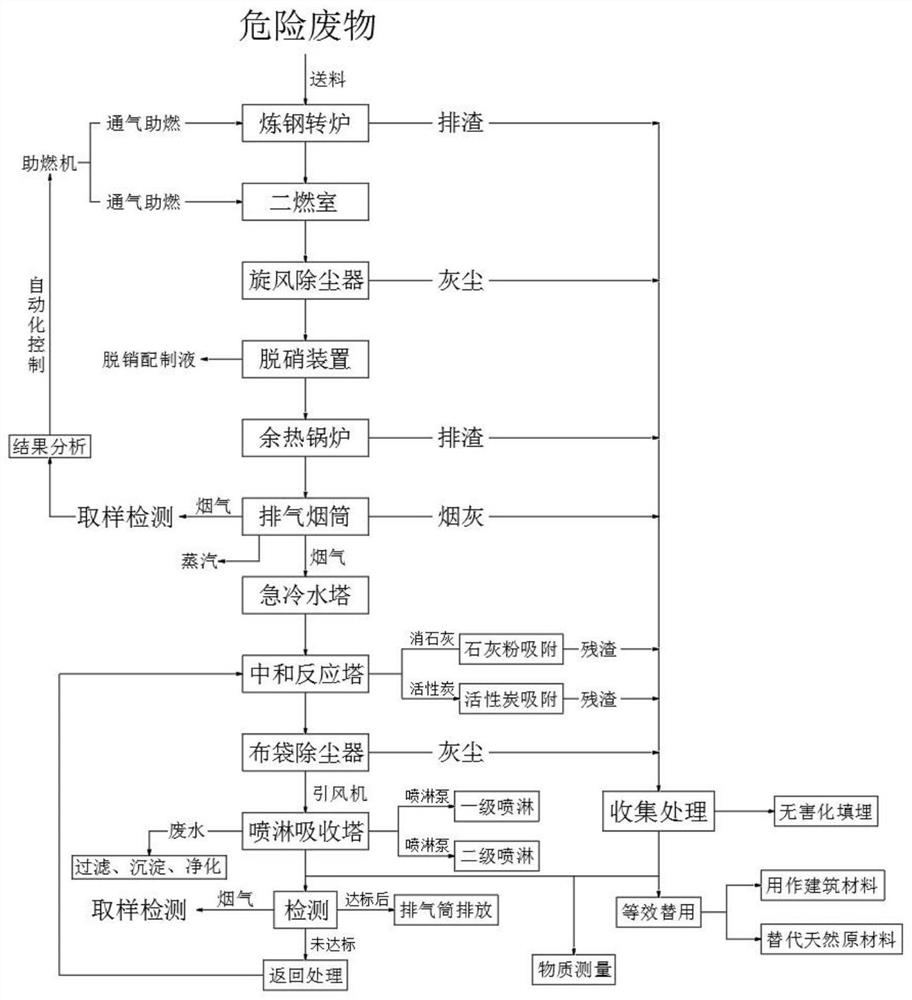

[0052] Embodiment 1: as figure 1 As shown, the present invention provides a kind of technical scheme, the pollutant control process of steelmaking converter processing hazardous waste, comprising the following processing steps:

[0053] S1. Incineration co-processing;

[0054] S2, cyclone dust removal;

[0055] S3, denitrification treatment;

[0056] S4, waste heat treatment;

[0057] S5, rapid cooling;

[0058] S6, neutralization and adsorption;

[0059] S7, bag dust removal;

[0060] S8, spray absorption;

[0061] S9. Pollutant treatment.

[0062] Based on the above technical solution, in S1, incineration co-processing means that the solid hazardous waste and liquid hazardous waste to be treated are transported to the steelmaking converter through the supply hopper after being processed, and the hazardous waste is combined with combustible fuel for incineration Co-processing, and after co-processing, the slag is discharged and collected from the steelmaking converter...

Embodiment 2

[0087] Embodiment 2: as figure 1 As shown, the present invention provides a kind of technical scheme, the pollutant control process of steelmaking converter processing hazardous waste, comprising the following processing steps:

[0088] S1. Incineration co-processing;

[0089] S2, cyclone dust removal;

[0090] S3, denitrification treatment;

[0091] S4, waste heat treatment;

[0092] S5, rapid cooling;

[0093] S6, neutralization and adsorption;

[0094] S7, bag dust removal;

[0095] S8, spray absorption;

[0096] S9. Pollutant treatment.

[0097] Based on the above technical solution, in S1, incineration co-processing means that the solid hazardous waste and liquid hazardous waste to be treated are transported to the steelmaking converter through the supply hopper after being processed, and the hazardous waste is combined with combustible fuel for incineration Co-processing, and after co-processing, the slag is discharged and collected from the steelmaking converter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com