Communication maintenance system and maintenance method for aircraft test

A technology for maintenance systems and aircraft testing, which is applied in the field of communication maintenance systems for aircraft testing. It can solve problems such as poor sealing of threading holes, increased fresh air flow, and damage to test pieces, so as to ensure heat preservation, safety, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

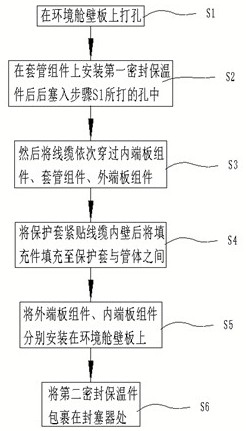

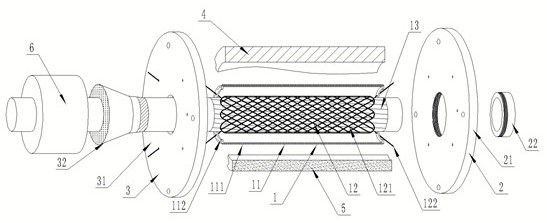

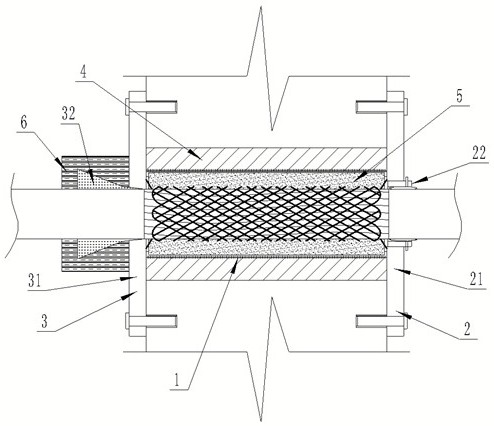

[0042] Such as figure 2 , 3 A communication maintenance system for aircraft testing is shown, including a maintenance kit and a sealed and heat-insulated assembly for sealing and insulating the maintenance kit; the maintenance kit includes a sleeve assembly 1 that can pass through the environmental bulkhead, and can be installed in the An outer end plate assembly 2 on the outer wall of the bulkhead plate and capable of being connected to one end of the sleeve assembly 1, and an inner end plate assembly 3 capable of being installed on the inner wall of the environmental bulkhead plate and capable of being connected to the other end of the sleeve assembly 1; the sleeve assembly 1 includes a sleeve body 11, a telescopic sleeve 12 movably installed inside the sleeve body 11, and a protective sleeve 13 for protecting cables;

[0043] Such as figure 2 As shown, the sleeve body 11 includes a tube body 111 and a ring 112 arranged at both ends of the tube body 111; the ring 112 is ...

Embodiment 2

[0065] The difference from Embodiment 1 is that the cross sections of the outer end plate body 21 and the inner end plate body 31 are square.

Embodiment 3

[0067] The difference with embodiment 1 is: as Image 6 As shown, the aperture adjuster 22 adopts the second aperture adjuster 222; the second aperture adjuster 222 includes a second base pipe 2221 that can be movably arranged on the outer end plate body 21, and two installations arranged inside the second base pipe 2221 Pad 2222, an extrusion ring 2223 arranged between the two installation pads 2222, two extrusion blocks 2224 respectively arranged on the upper and lower ends of the extrusion ring 2223 and two respectively passing through the upper and lower surfaces of the second base pipe 2221 Adjusting bolts 2225 that are movably connected with the two extruding blocks 2224 respectively.

[0068] When the communication maintenance system proposed in this embodiment is used to pass the cable through the environmental bulkhead panel: before the cable is passed through the aperture regulator 22, the adjusting bolt 2225 needs to be adjusted to a loose state, and then the cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com