Reaction kettle and polyethylene production method

A technology of reaction kettle and kettle body, which is applied in the production field of reaction kettle and polyethylene, can solve the problems of lack of good coordination and matching, and can achieve the effect of strengthening stirring and mixing, effectively controlling temperature, changing good thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

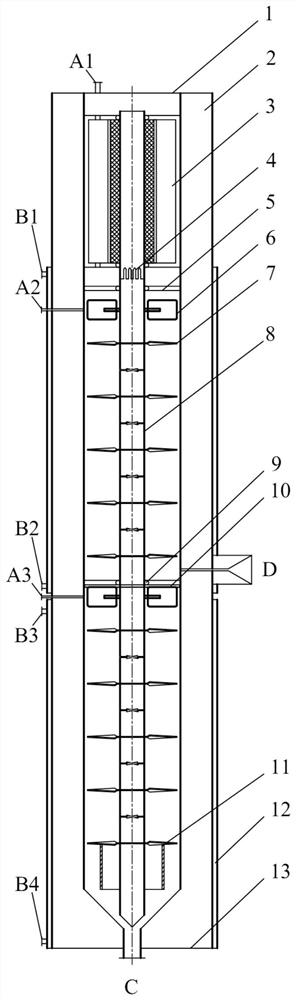

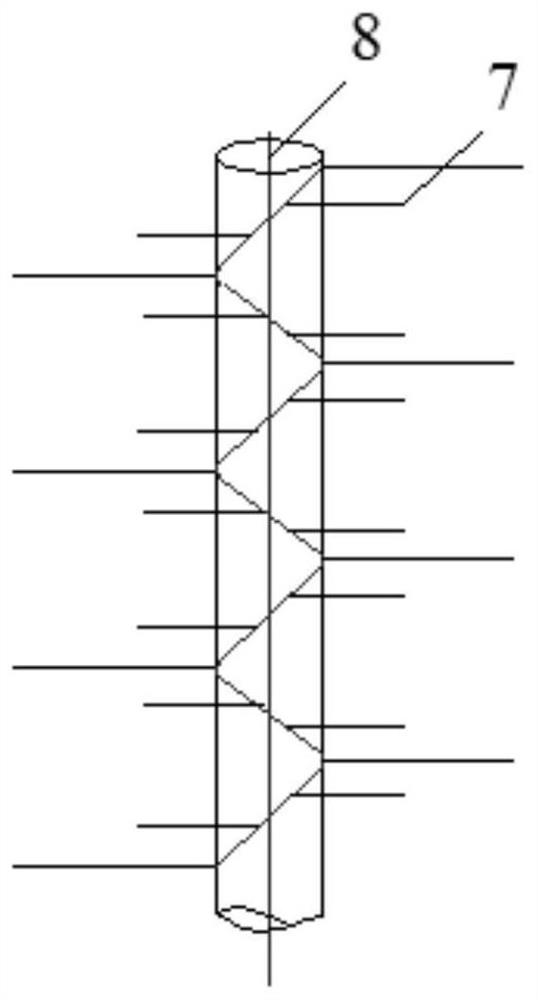

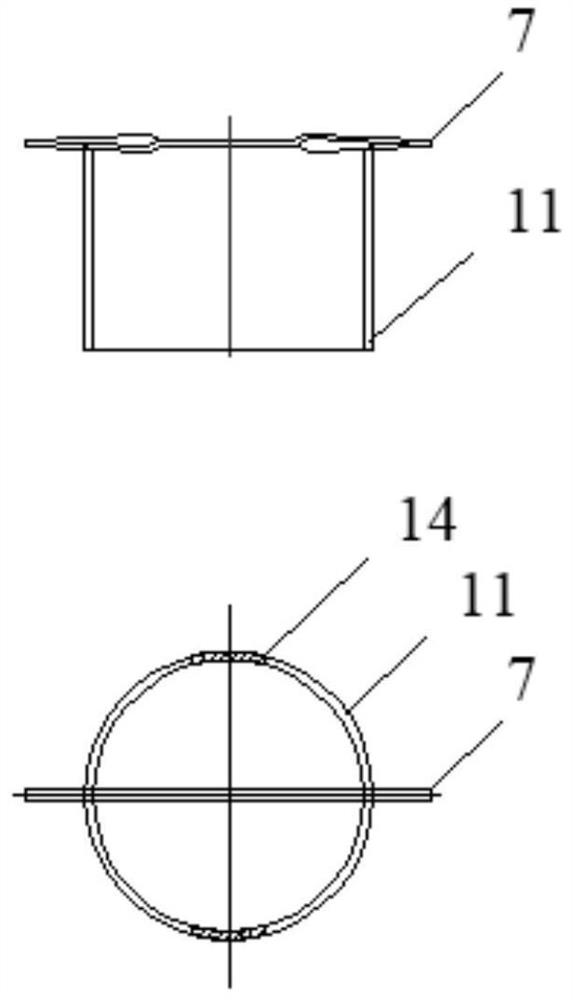

[0077] a use attached figure 1 The plant for the production of low density polyethylene from the reactor shown includes a first compressor for compressing ethylene to intermediate pressure upstream of the reactor and a second compressor for compressing ethylene to reaction pressure; located upstream of the reactor Downstream, a high-pressure separator for separating unreacted ethylene and polyethylene, a low-pressure separator for separating ethylene and volatile oligomer components. Among them, the inner diameter of the reactor is 500mm, the height of the cylinder is 8000mm, the shaft diameter is 145mm, the total length of the shaft is 5500mm, and the length of the lower extension shaft is 2750mm; 9 layers of inclined blade axial flow paddles are evenly distributed between the upper runoff paddle and the horizontal partition; in the middle Between the radial flow propeller and the stabilizer, 9 layers of inclined-blade axial-flow propellers are evenly distributed, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com