Preparation method for regulating and controlling morphology of two-dimensional VA family layered material by using solution polarity

A technology of layered materials and solutions, which is applied in the field of preparation of two-dimensional VA group layered materials by using the polarity of the solution to control the morphology of layered materials, can solve the problems of harsh growth conditions, high preparation costs, high operating conditions, etc., and meet the requirements of growth conditions Low, reduced processing steps, fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

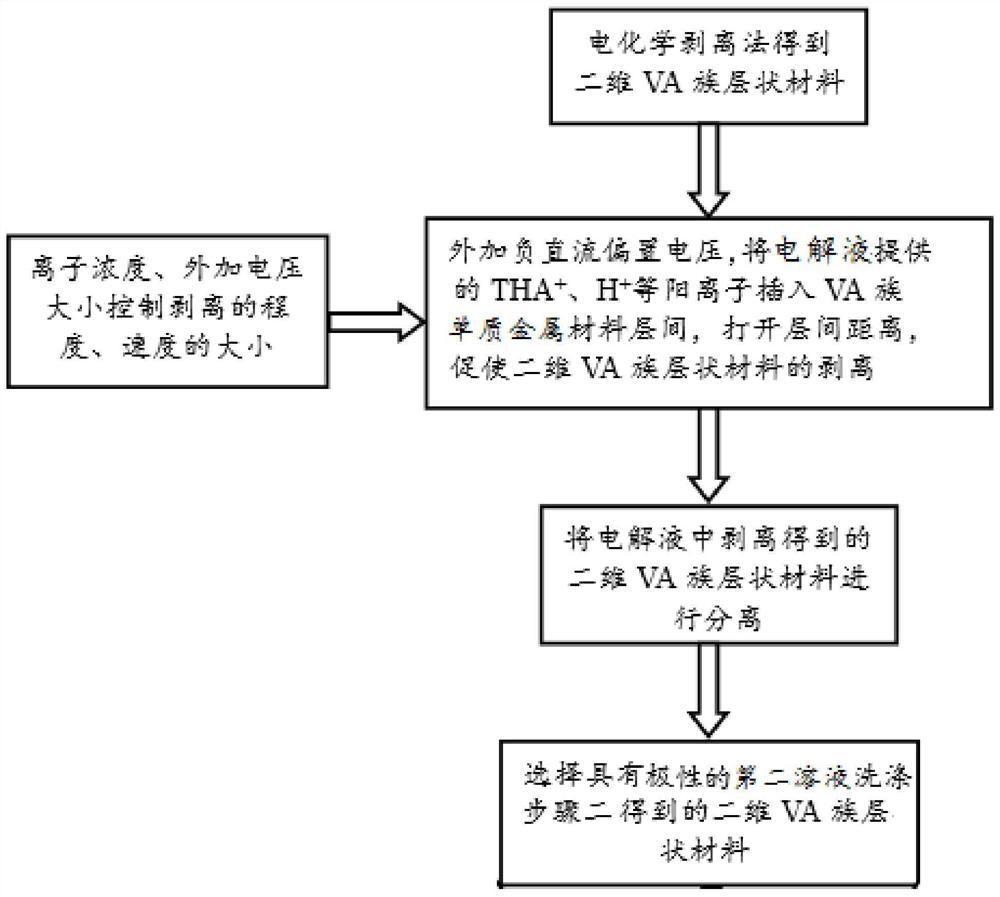

[0026] A preparation method for controlling the morphology of two-dimensional VA group layered materials by using the polarity of the solution, such as figure 1 shown, including the following steps:

[0027] Step 1, preparing two-dimensional VA group layered materials by electrochemical exfoliation method, specifically:

[0028] The solute of the electrolyte in the electrochemical stripping method is tetrapropylammonium bromide powder, and the solvent is an organic solvent; the VA group elemental metal material is used as the cathode (ie, the working electrode), the platinum sheet is used as the counter electrode, and Ag / AgCl is used as the reference electrode. (called Ag / AgCl reference electrode), build a three-electrode system connected to the electrochemical reaction system, provide a constant DC bias voltage, and perform electrochemical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com