Growth method of Si NWs (at) ZIF-8 core-shell structure

A growth method and core-shell structure technology are applied in the growth field of SiNWs@ZIF-8 core-shell structure to achieve the effects of complete coating, simple preparation process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

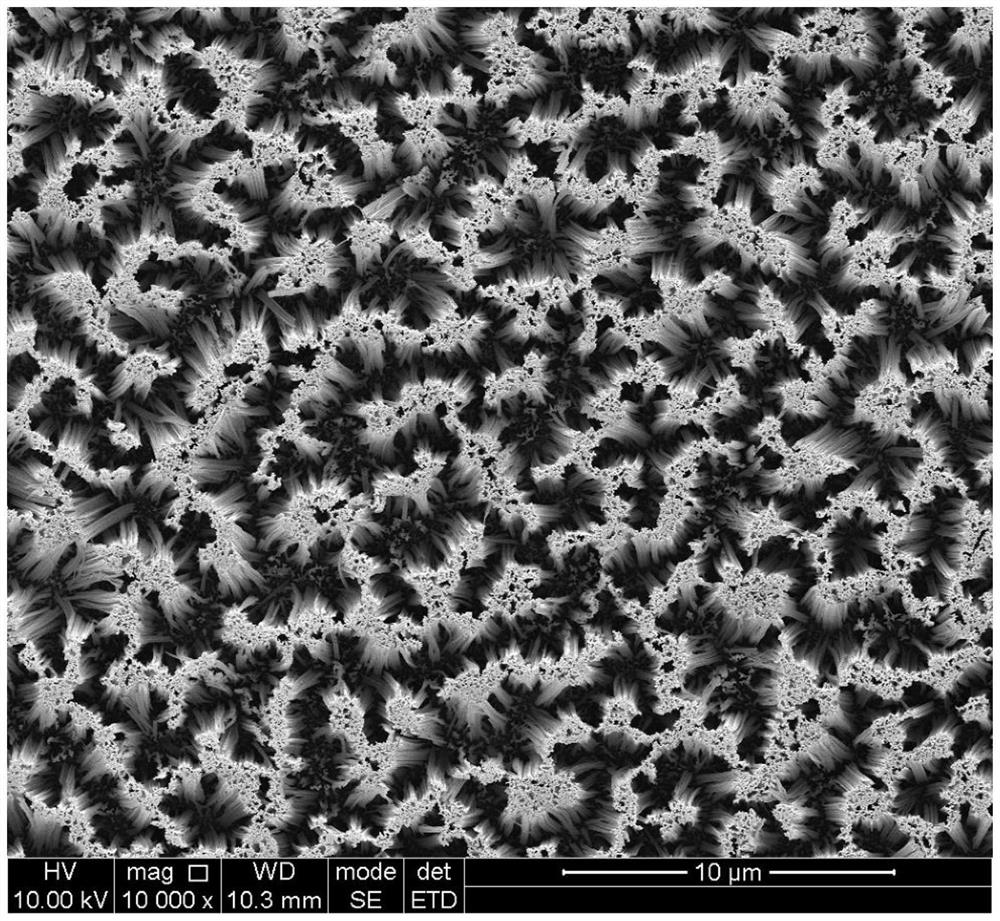

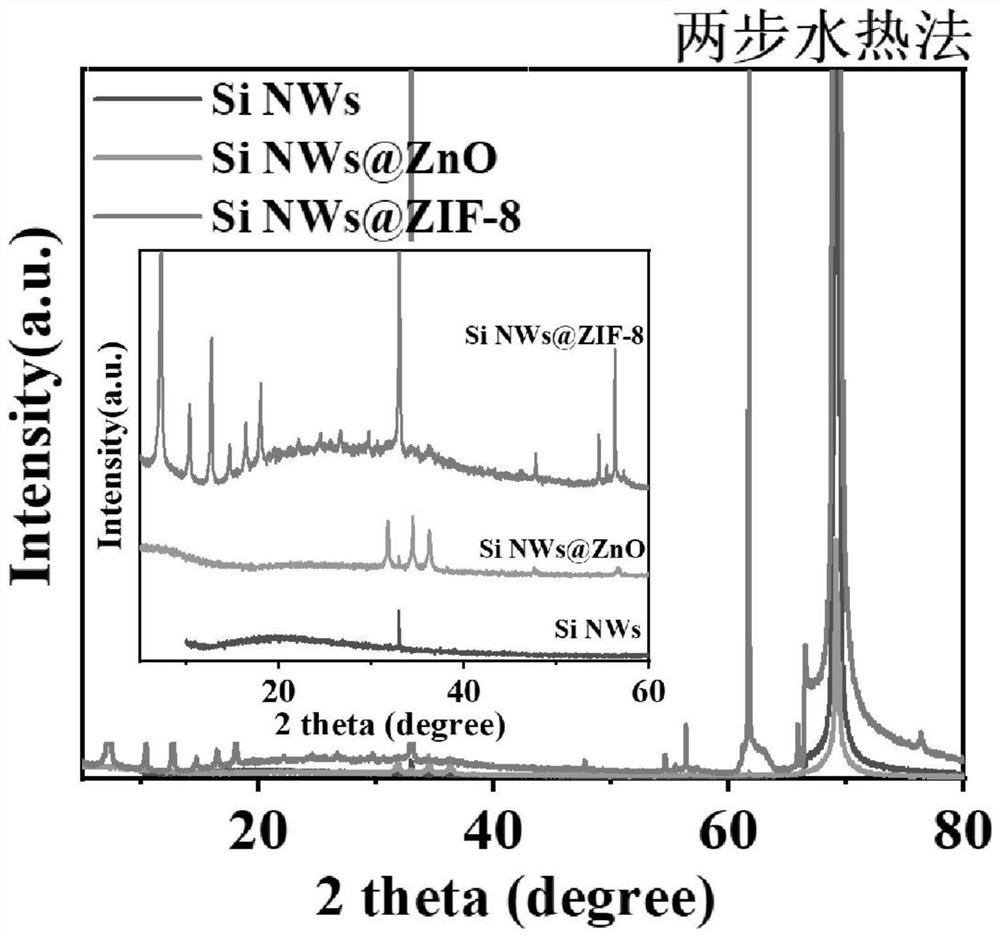

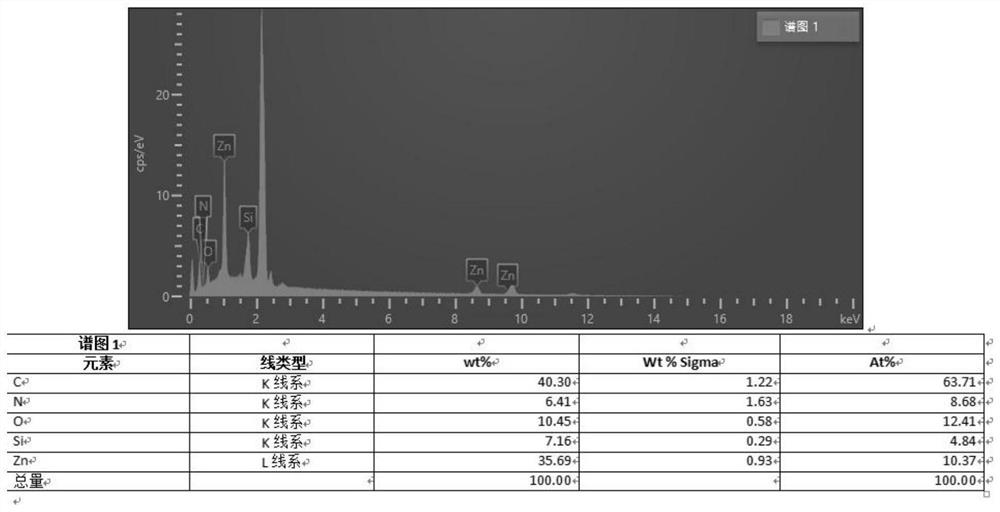

Image

Examples

Embodiment 1

[0065] A growth method of Si NWs@ZIF-8 core-shell structure, comprising the following steps:

[0066] S1, silicon wafer cleaning

[0067] S11. Put the silicon wafers into methanol (CH 3 OH) and absolute ethanol (C 2 H 5 OH) in ultrasonic cleaning for 2min to remove oil and organic matter;

[0068] S12, put the above-mentioned silicon wafer into concentrated sulfuric acid (H 2 SO 4 ): hydrogen peroxide (H 2 O 2 )=3:1 (volume ratio) in the mixed solution for 2h, until no more bubbles are generated in the beaker, rinse with deionized water after the end;

[0069] S13, put the above silicon wafer into hydrofluoric acid (HF): deionized water (H 2 O)=1:3 (volume ratio) in the mixed solution for 1min to remove the oxide layer; rinse with deionized water after finishing;

[0070] S14, put the above silicon wafers into methanol (CH 3 OH) and absolute ethanol (C 2 H 5 OH) in ultrasonic cleaning for 2min;

[0071] S15, take out the above-mentioned silicon wafer and put it in...

Embodiment 2

[0092] A growth method of Si NWs@ZIF-8 core-shell structure, comprising the following steps:

[0093] S1, silicon wafer cleaning

[0094] S11. Put the silicon wafers into methanol (CH 3 OH) and absolute ethanol (C 2 H 5 OH) in ultrasonic cleaning for 4min to remove oil and organic matter;

[0095] S12, put the above-mentioned silicon wafer into concentrated sulfuric acid (H 2 SO 4 ): hydrogen peroxide (H 2 O 2 )=3:1 (volume ratio) in the mixed solution for 2h, until no more bubbles are generated in the beaker, rinse with deionized water after the end;

[0096] S13, put the above silicon wafer into hydrofluoric acid (HF): deionized water (H 2 O)=1:3 (volume ratio) in the mixed solution of immersion for 2min to remove the oxide layer; rinse with deionized water after finishing;

[0097] S14, put the above silicon wafers into methanol (CH 3 OH) and absolute ethanol (C 2 H 5 OH) in ultrasonic cleaning for 4min;

[0098] S15, take out the above-mentioned silicon wafer ...

Embodiment 3

[0118] A growth method of Si NWs@ZIF-8 core-shell structure, comprising the following steps:

[0119] S1, silicon wafer cleaning

[0120] S11. Put the silicon wafers into methanol (CH 3 OH) and absolute ethanol (C 2 H 5 OH) in ultrasonic cleaning for 5min to remove oil and organic matter;

[0121] S12, put the above-mentioned silicon wafer into concentrated sulfuric acid (H 2 SO 4 ): hydrogen peroxide (H 2 O 2 )=3:1 (volume ratio) in the mixed solution for 2h, until no more bubbles are generated in the beaker, rinse with deionized water after the end;

[0122] S13, put the above silicon wafer into hydrofluoric acid (HF): deionized water (H 2 O)=1:3 (volume ratio) in the mixed solution of immersion for 2min to remove the oxide layer; rinse with deionized water after finishing;

[0123] S14, put the above silicon wafers into methanol (CH 3 OH) and absolute ethanol (C 2 H 5 OH) in ultrasonic cleaning for 5min;

[0124] S15, take out the above-mentioned silicon wafer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com