Modified organic silicon defoaming agent and preparation method thereof

An organosilicon defoamer and modification technology, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problem that the surface liquid of the defoamer is easily oxidized, reduces the defoaming and foam suppression performance, and has poor stability. and other problems to achieve the effect of ensuring stability and use effect, reducing water foam, and improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

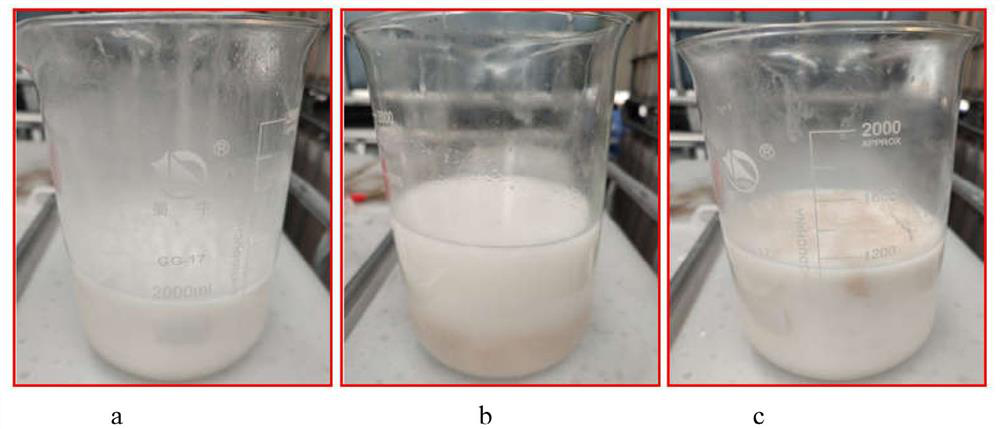

Image

Examples

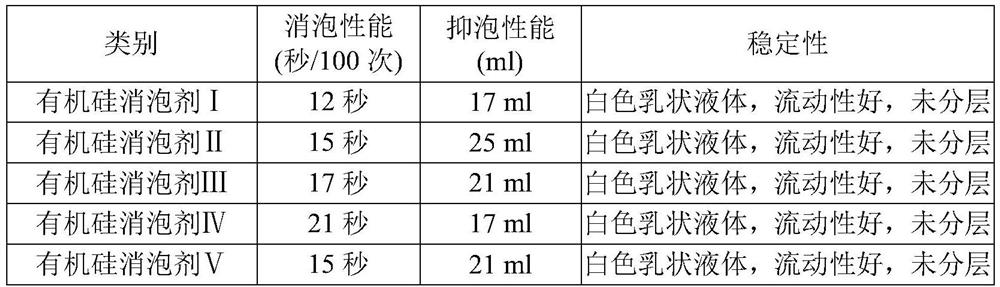

Embodiment 1

[0029] Add 60g of simethicone oil to the beaker, under stirring (150r / min), slowly add 5g of hydrophobic fumed silica, and after stirring for 1 hour, add 35.5g of high boiling silicone oil to make a silicone paste. After raising the temperature to 120° C., the temperature was kept for 3 hours. After the temperature drops to 40°C, add Span-Tween mixed emulsifier (17.5g each of Span-80 and Tween-80), and after stirring for 30 minutes, continue to add polyvinyl alcohol aqueous solution (dissolve 16.5g polyvinyl alcohol in 200g deionized water), 0.5g sodium citrate and 150g deionized water, and emulsified for 2 hours under stirring at 2500r / min to obtain silicone defoamer I.

Embodiment 2

[0031] Add 60g of simethicone to the beaker, and slowly add 2.5g of hydrophobic fumed silica and 2.5g of hydrophilic fumed silica under stirring (150r / min), and then add 35.5g of fumed silica after stirring for 1 hour High-boiling silicone oil is used to make silicone paste, and the temperature of the silicone paste is raised to 120°C and then kept for 3 hours. After the temperature drops to 40°C, add Span-Tween mixed emulsifier (17.5g each of Span-80 and Tween-80), and after stirring for 30 minutes, continue to add polyvinyl alcohol aqueous solution (dissolve 16.5g polyvinyl alcohol in 200g deionized water), 0.5g of sodium citrate and 150g of deionized water, and emulsified for 2 hours under stirring at 2500r / min to obtain silicone defoamer II.

Embodiment 3

[0033] Add 80g of simethicone oil to the beaker, under stirring (200r / min), slowly add 5g of hydrophobic fumed silica and 2g of hydrophilic fumed silica, stir for 1 hour, then add 50g of high boiling silicone oil Make a silicone paste, heat the silicone paste to 120°C and keep it warm for 4 hours. After the temperature drops to 40°C, add Span-Tween mixed emulsifier (20g Span-80 and 24g Tween-80), and after stirring for 30 minutes, continue to add polyvinyl alcohol aqueous solution (dissolve 16.5g polyvinyl alcohol in 200g deionized water), 0.5g sodium citrate, 0.5g ascorbic acid, and 200g deionized water, and emulsified for 1 hour under stirring at 2500r / min to obtain silicone defoamer III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com