Modified asphalt coating material, method for preparing modified asphalt coating material and asphalt waterproof coiled material

A kind of asphalt waterproof membrane and modified asphalt technology, which is applied in the direction of asphalt material adhesives, film/sheet adhesives, other rubber adhesives, etc., and can solve the problem of durability, low temperature flexibility and poor bonding performance and other issues, to achieve the effect of improving compatibility, meeting application requirements, improving durability and low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

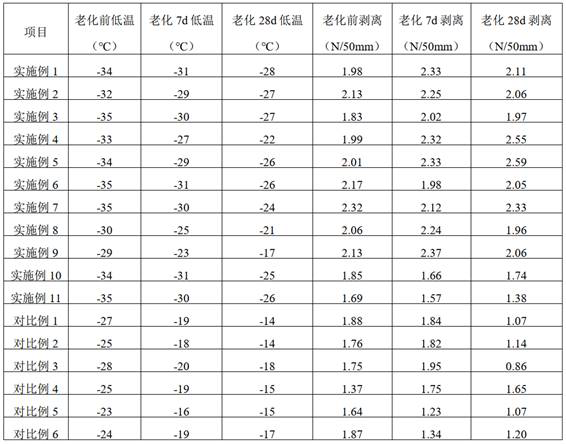

Examples

Embodiment 1

[0071] Modified asphalt coating material

[0072] A modified asphalt coating material, comprising the following raw materials by weight: 90# asphalt, 100 parts; trioctyl phosphate, 1.5 parts; rubber oil, 45 parts; SBS, 8 parts; SBR, 7 parts; tire Rubber powder, 50 parts; heavy calcium, 50 parts.

[0073] (1) Mix 90# asphalt, trioctyl phosphate and rubber oil according to the ratio, stir the mixture at a speed of 1000rpm, raise the temperature to 140~145°C and keep it warm for 1.5h until the asphalt is completely melted;

[0074] (2) Add SBS and SBR to the mixture after step (1) in accordance with the ratio, raise the temperature to 170~180°C and keep it warm for 1.5h;

[0075] (3) Add tire rubber powder to the mixture after heat preservation in step (2) according to the ratio, raise the temperature to 170~180°C, and shear and disperse at this temperature at a speed of 1000rpm for 2.5h;

[0076] (4) Add heavy calcium powder to the mixture after shear dispersion in step (3), ...

Embodiment 2

[0081] The preparation of the modified asphalt coating material and the asphalt waterproofing membrane are the same as in Example 1, the difference is that the content of each component in the modified asphalt coating material is different from that of Example 1, and each component is in parts by weight: 90 #Asphalt, 100 parts; trioctyl phosphate, 0.5 parts; rubber oil, 40 parts; SBS, 5 parts; SBR, 5 parts; tire rubber powder, 40 parts; heavy calcium, 40 parts.

Embodiment 3

[0083] The preparation of the modified asphalt coating material and the asphalt waterproofing membrane are the same as in Example 1, the difference is that the content of each component in the modified asphalt coating material is different from that of Example 1, and each component is in parts by weight: 90 #Asphalt, 100 parts; trioctyl phosphate, 3 parts; rubber oil, 50 parts; SBS, 10 parts; SBR, 10 parts; tire rubber powder, 60 parts; heavy calcium, 60 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com