A method for recovering vanadium and tungsten at the same time by reconstituting titanium dioxide with spent SCR denitrification catalyst

A technology of denitrification catalyst and titanium dioxide, which is applied in the field of solid waste treatment, can solve the problems of unrestored deteriorated channels, low leaching rate and recovery purity of V and W, incomplete removal of impurities, etc., and achieve the improvement of environmental protection technology level, high leaching efficiency, The effect of pore structure restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

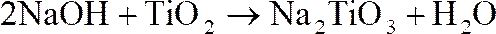

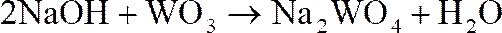

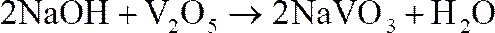

Method used

Image

Examples

Embodiment 1

[0044] Wash the waste SCR denitrification catalyst raw material with high-pressure water to remove dust and other impurities, then dry, grind, and sieve (100 mesh), and collect the powder for subsequent processing. Mix 2 g of powder with 3% hydrofluoric acid solution, the solid-to-liquid ratio is 1:4, turn on the ultrasonic wave, the intensity is 200W, heat to 110°C, stir for 4 h, collect the Ti-W-V filter cake after filtering and washing. Ti-W-V filter cake is mixed with 30% sodium hydroxide solution, the amount of sodium hydroxide added is 1.5 times of the theoretical value, and the mixed slurry is added to the planetary ball mill, and 2 mm zirconia balls are added, and the powder is mixed with The mass ratio of the balls was 1:80, and the milling speed was 300 rpm for 3 hours. After the reaction, it was filtered and washed, and the solid was collected as Ti filter cake, and the filtrate was collected as W-V filtrate. Ti filter cake was mixed with 10% dilute sulfuric acid so...

Embodiment 2

[0047] Wash the waste SCR denitrification catalyst raw material with high-pressure water to remove dust and other impurities, then dry, grind, and sieve (100 mesh), and collect the powder for subsequent processing. Mix 2 g of powder with 3% hydrofluoric acid solution, the solid-to-liquid ratio is 1:8, turn on the ultrasonic wave, the intensity is 200W, heat to 110°C, stir for 4 h, collect the Ti-W-V filter cake after filtering and washing. The Ti-W-V filter cake was mixed with a 30% sodium hydroxide solution, the amount of sodium hydroxide added was twice the theoretical value, and the mixed slurry was added to a planetary ball mill, and 2 mm zirconia balls were added, and the powder was mixed with The mass ratio of the balls was 1:80, and the milling speed was 300 rpm for 3 h. After the reaction, it was filtered and washed to collect the solid as Ti filter cake and the collected filtrate as W-V filtrate. Ti filter cake was mixed with 10% dilute sulfuric acid solution, stirred...

Embodiment 3

[0050] Wash the waste SCR denitrification catalyst raw material with high-pressure water to remove dust and other impurities, then dry, grind, and sieve (100 mesh), and collect the powder for subsequent processing. Mix 2 g of powder with 4% hydrofluoric acid solution, the solid-to-liquid ratio is 1:8, turn on the ultrasonic wave, the intensity is 200W, heat to 110°C, stir for 4 h, collect the Ti-W-V filter cake after filtering and washing. The Ti-W-V filter cake was mixed with a 40% sodium hydroxide solution, the amount of sodium hydroxide added was twice the theoretical value, and the mixed slurry was added to a planetary ball mill, and 2 mm zirconia balls were added, and the powder was mixed with The mass ratio of the balls was 1:80, and the milling speed was 500 rpm for 3 h. After the reaction, it was filtered and washed, and the solid was collected as Ti filter cake, and the filtrate was collected as W-V filtrate. Ti filter cake was mixed with 10% dilute sulfuric acid solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com