Alcohol-free amphiphilic texturing additive and preparation method thereof

An additive and amphiphilic technology, which is applied in the field of alcohol-free amphiphilic texturing additive and its preparation, can solve the problems of weak silicon adsorption, achieve high-efficiency texturing performance, good application prospects, and good large-scale industrialization promotion potential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

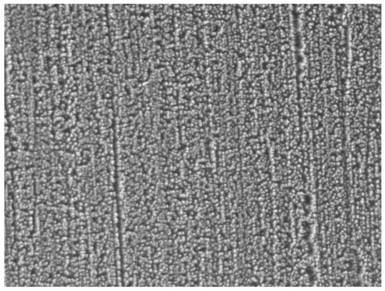

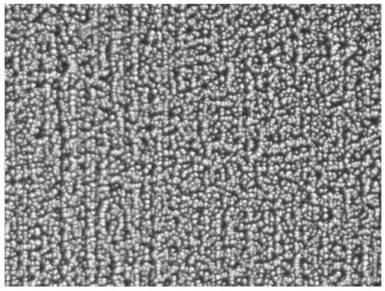

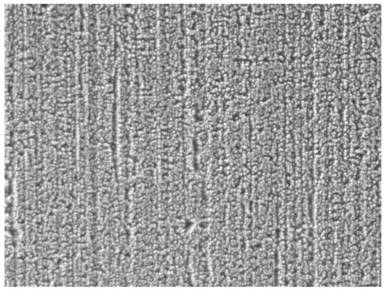

Image

Examples

Embodiment 1-10

[0032] According to the amount of the components in each of the following table, it is called, and the polysaccharide is added to the inorganic base solution, and the mixture is dissolved in the inorganic base solution, and the mixture is dissolved in the inorganic base solution. .

[0033] Table 1 Embodiment 1-10 of the components

[0034]

[0035]

Embodiment 11

[0040] Example 11 Test when used in failure

[0041] Test methods for failure, including the following steps:

[0042](1) The obtained an aqueous solution prepared by the prepared formulation of an example is 0.1%, and then the NaOH solid of 2% of the NaOH mass concentration is added;

[0043] (2) Preparation of a solution of a concentration of a concentration of a concentration of a concentration of a concentration of 0.1%, and then a NaOH solid having a NaOH mass concentration of 2%;

[0044] (3) Eleged liquid prepared by heating step (1) and (2) at 85 ° C, and the falling liquid temperature reached at 85 ° C, and placed in a single crystal silicon wafer to the reaction tank, and the reaction was 360s Silicon wafer, rinse the front and negative surface with pure water 15s, add N 2 Dry under the atmosphere. Since then, a phenotypy is performed every 2h, and the appearance of the four flavor flake appearance is obviously deteriorated.

Embodiment 12

[0045] Example 12 Silicon wafer weight loss test

[0046] Test methods for wafers weight loss, including the following steps:

[0047] (1) The obtained an aqueous solution prepared by the prepared formulation of an example is 0.1%, and then the NaOH solid of 2% of the NaOH mass concentration is added;

[0048] (2) Preparation of a solution of a concentration of a concentration of a concentration of a concentration of a concentration of 0.1%, and then a NaOH solid having a NaOH mass concentration of 2%;

[0049] (3) Heating steps (1) and (2) prepared from the flavor to 85 ° C; 2 sets of single crystal silicon wafers, 10 pieces per group, recorded in group I and II; use the preparation of the present invention The pile of the velvet additive was continuously velvet in group I, and the set of silicon wafers containing the II group silicon containing the existing product. The silicon wafer was dried. The weight changes before and after the reaction of the silicon film, thereby examini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com