Integrated slurry pump and manufacturing mold thereof

A technology for slurry pumps and molds, applied to pumps for special fluids, parts of pumping devices for elastic fluids, pumps, etc., can solve problems such as difficult assembly, complex structure, and difficulty in ensuring sealing performance, and achieve improved sealing High performance, high strength and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

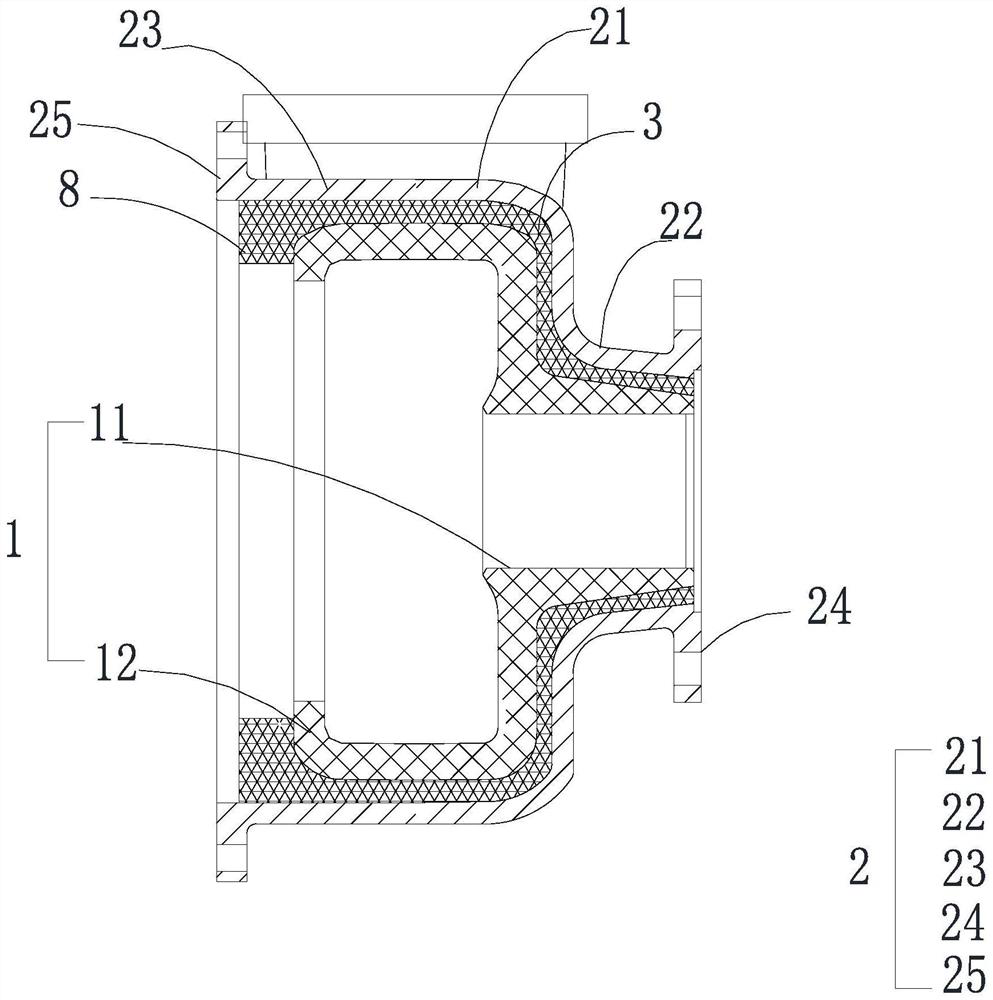

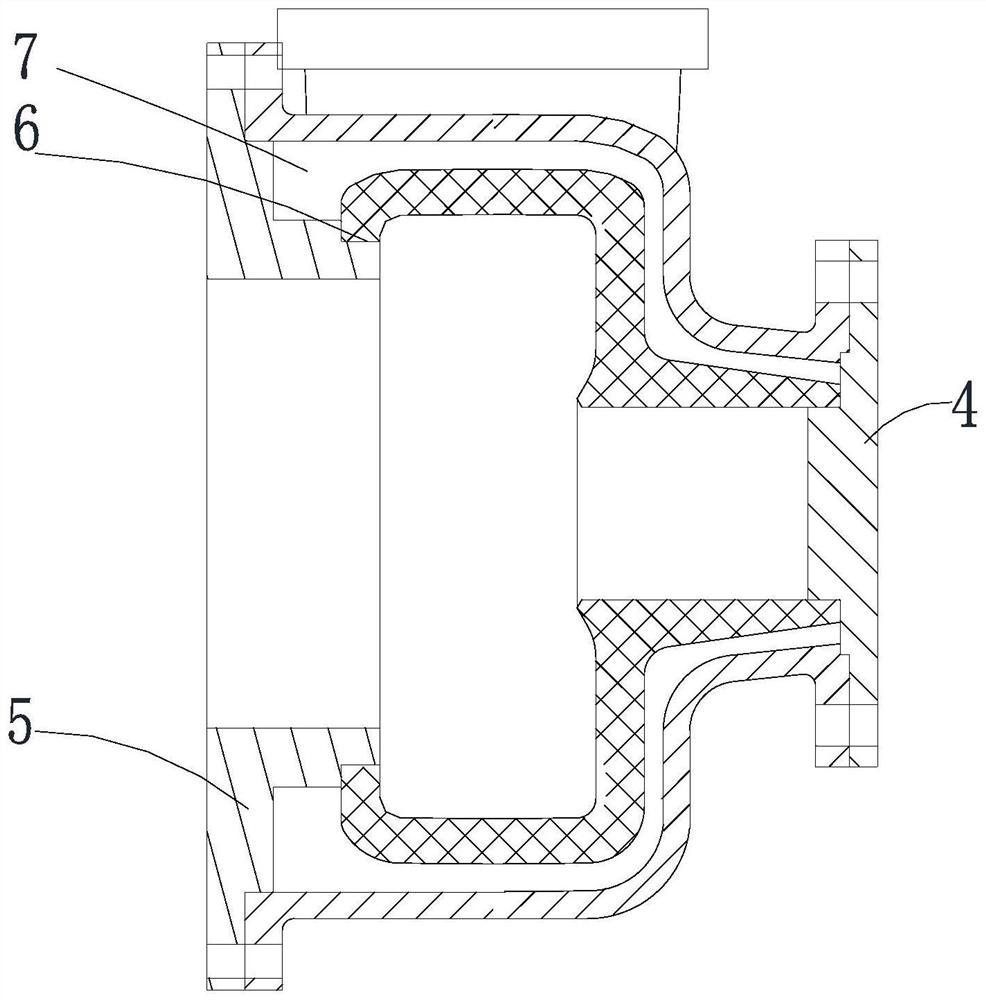

[0028] Integrated slurry pump, such as figure 1 As shown, it includes a volute 1 and a pump casing 2. The pump casing 2 includes a cylindrical pump body 21. The diameter of one side of the pump body 21 shrinks toward the axial direction to form a suction port 22, and the other side is provided with a connection port 23. The diameter of the connection port 23 is The diameter of the main body 21 of the pump is the same, and the size of the connection port 23 allows the volute 1 to be embedded in the pump casing 2. A volute suction port 11 is provided on one side of the volute 1, and the volute suction port 11 is embedded in the suction port 22 of the pump casing 1. , A sealed cavity is provided between the volute 1 and the pump casing 2, and the sealed cavity is filled with an organic-inorganic composite ceramic layer 3, and the constriction portion 12 is set on the side of the volute 1 close to the connection port 23 of the pump casing 2. The suction port 22 of the pump casing ...

Embodiment 2

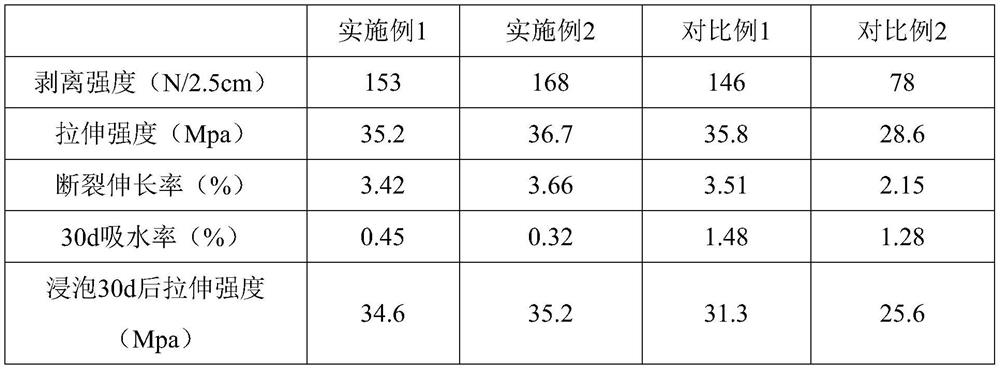

[0036] The difference between Example 2 and Example 1 is that the resin silicon carbide sand layer consists of 8 parts by mass of modified epoxy resin, 3 parts of coupling agent, 1 part of curing agent diethylenetriamine, and 100 parts of silicon carbide sand. The modified epoxy resin is prepared by reacting 8 parts of epoxy resin, 0.5 part of terephthalic acid and 0.2 part of tetrabutylammonium fluoride. The preparation method is as follows:

[0037] Get 8 parts of epoxy resins and dissolve with n-butanol, join in the four-necked flask that thermometer, stirrer, condenser are housed, add and account for the benzoyl peroxide of 0.5% epoxy resin massfraction again as initiator, Under the protection of nitrogen, raise the temperature of the system to 90-100°C, and slowly add 0.5 parts of terephthalic acid into the system dropwise. After 4 hours of constant temperature reaction, 0.1 part of tetrabutylammonium fluoride was added to the system, the constant temperature reaction wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com