Color-changing material based on metal nanoparticles and application of color-changing material

A technology of metal nanoparticles and color-changing materials, which is applied in the direction of analyzing materials through chemical reactions and observing the influence of chemical indicators on materials, etc. It can solve the problem that the light response cannot meet the needs of visualization, and there are few multi-modes. Respond to problems such as the visual system to achieve a significant color change effect, achieve energy consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The metal nanoparticles are preferably surface-modified metal nanoparticles, and the surface modifiers employed include, but are not limited to, sodium citrate or polyvinylpyrrolidone. The color type and responsiveness can be adjusted by modification of metal nanoparticles. The preparation method of surface modified metal nanoparticles includes: adding water-soluble silver salts, surface modifiers, and reducing agents to deion water, reacted at 25-40 ° C for 0.5 to 2 h, then centrifugation, to give metal nanoplasts.

[0039] For example, in a specific embodiment, ion water (200 mL 18.25 Ω), silver nitrate (AGNO 3 200 μL of 0.1m), sodium citrate (NA 3 CA 12ml 75mm) and hydrogen peroxide (H 2 O 2 480 μl 30% of the solution was added to 250 ml of conical flask, and magnetically stirred in a constant temperature water bath at a constant temperature water bath at a constant temperature of 30 ° C. After a constant temperature, fresh borohydride (Nabh) 4 1.2ml 0.1m) Quickly inject i...

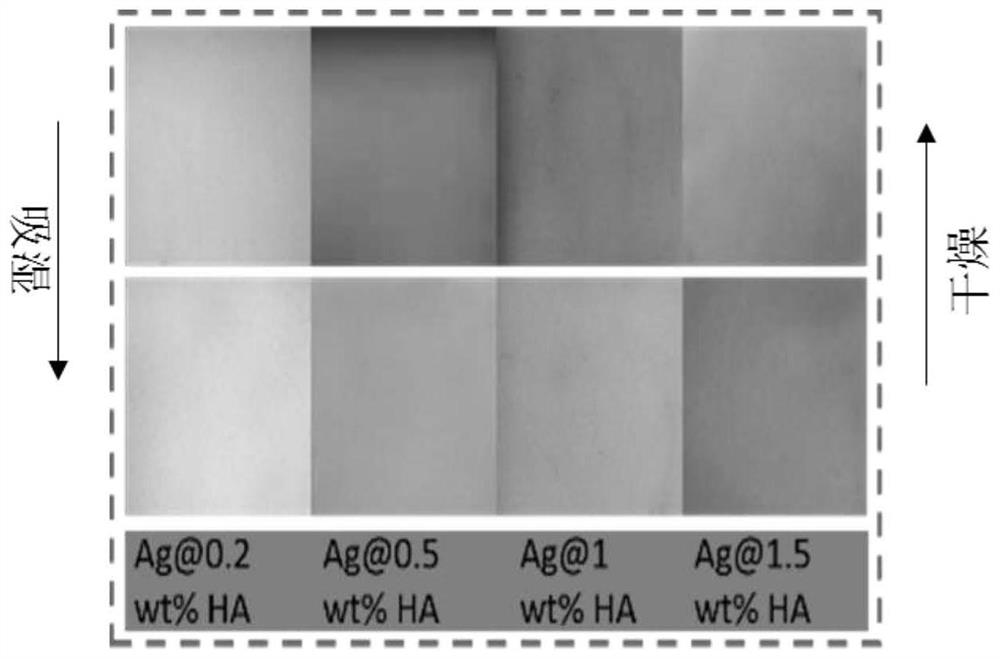

Embodiment 1-4

[0051] A discoloration composite film material based on metal nanoparticles, prepared by the following steps:

[0052] (1) Preparation of Silver Triangle Plate (TSCAG):

[0053] Remove ion water (200 mL 18.25Ω), silver nitrate (AGNO 3 200 μL 0.1M), sodium citrate (NA 3 Ca12ml 75mm), hydrogen (H 2 O 2 480 μl 30% of the solution was added to 250 ml of conical flask, and magnetically stirred in a constant temperature water bath at a constant temperature water bath at a constant temperature of 30 ° C. After a constant temperature, fresh borohydride (Nabh) 4 1.2ml 0.1m) Quickly inject into the conical bottle, you can see the solution quickly into yellow, orange, red, and finally become blue. At this time, the constant temperature water bath was continued for 15 min, then put it at a constant temperature cassette at 30 ° C for two hours, and the suspension of the silver triangle plate was centrifuged for two hours, and the suspension of the silver triangle plate was centrifuged.

[0054...

Embodiment 5-8

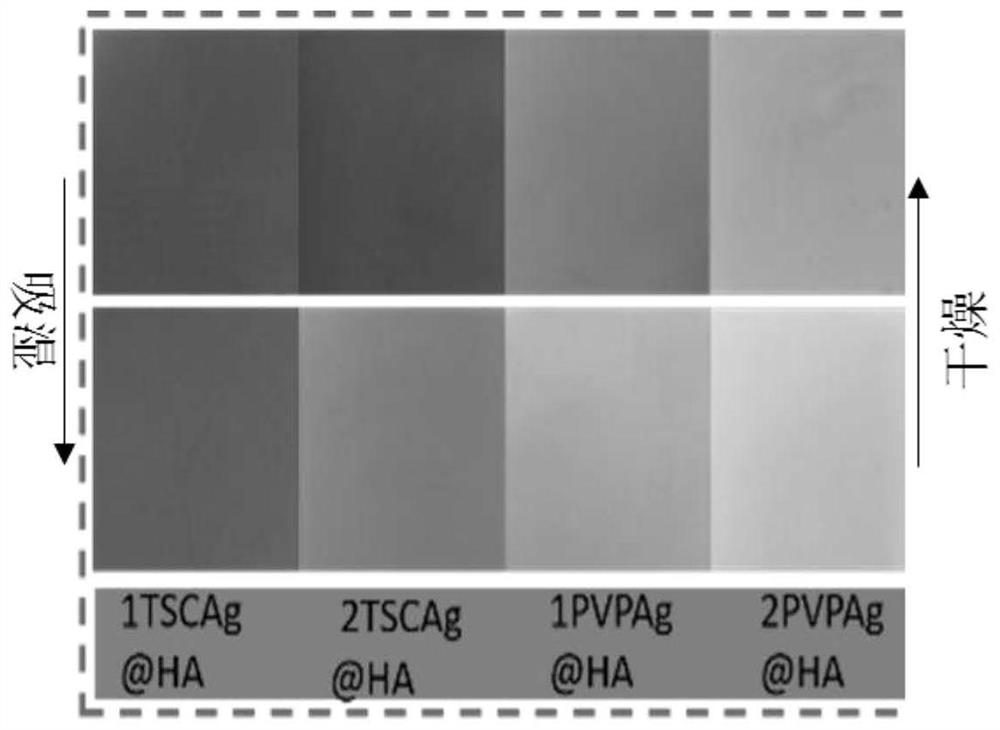

[0063] Example 5-8 The metal nanoplastic discoloration composite film material is provided, which is different from that of Example 4, and the silver triangle plate and different concentrations of sodium citrate in different concentrations are employed. Vinylpyrrolidone-modified silver triangle plate, to obtain the product, respectively, respectively, respectively, respectively, respectively, respectively, respectively, 2 TSCAG @ HA, and 1PVPAG @ HA, 2PVPAG @ HA. Others are substantially the same as in Example 4, and will not be described herein.

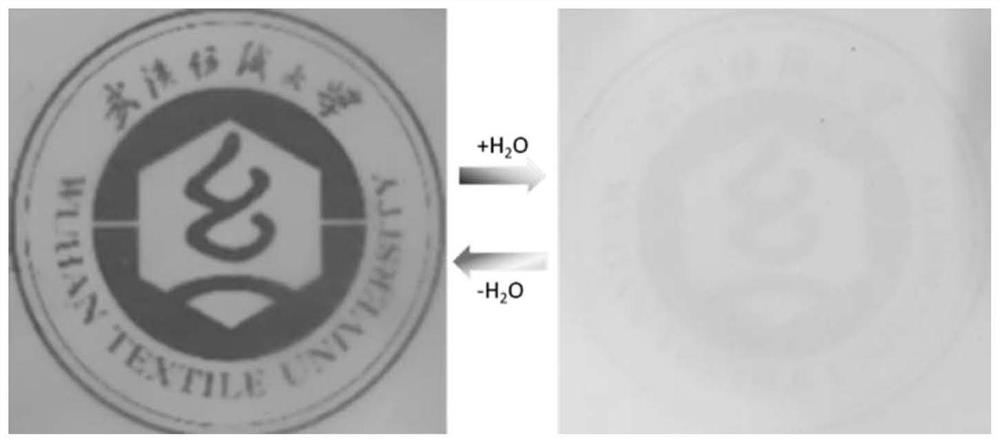

[0064] Example 5-8 The obtained moisture-sensitive test was prepared by the test method, and the test method was as follows: prepared a prepared film, and the film was given a moisture stimulus with a humidifier, and the color of the film changed immediately. Test results figure 2 Indicated.

[0065] from figure 2 It can be seen that the TSCAG @ HA material made by Example 5-6 presents the evolution of rose red to orange; Example 7-8 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com