A material with adjustable surface hydrophilicity/hydrophobicity and its preparation method

A hydrophobic and hydrophilic technology, applied in rayon manufacturing, filament/thread forming, physical treatment, etc., can solve the problems of inefficiency, change of material surface properties, etc., to achieve increased adhesion rate, reversible adjustment, material surface affinity Modulation of water/hydrophobic properties for efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

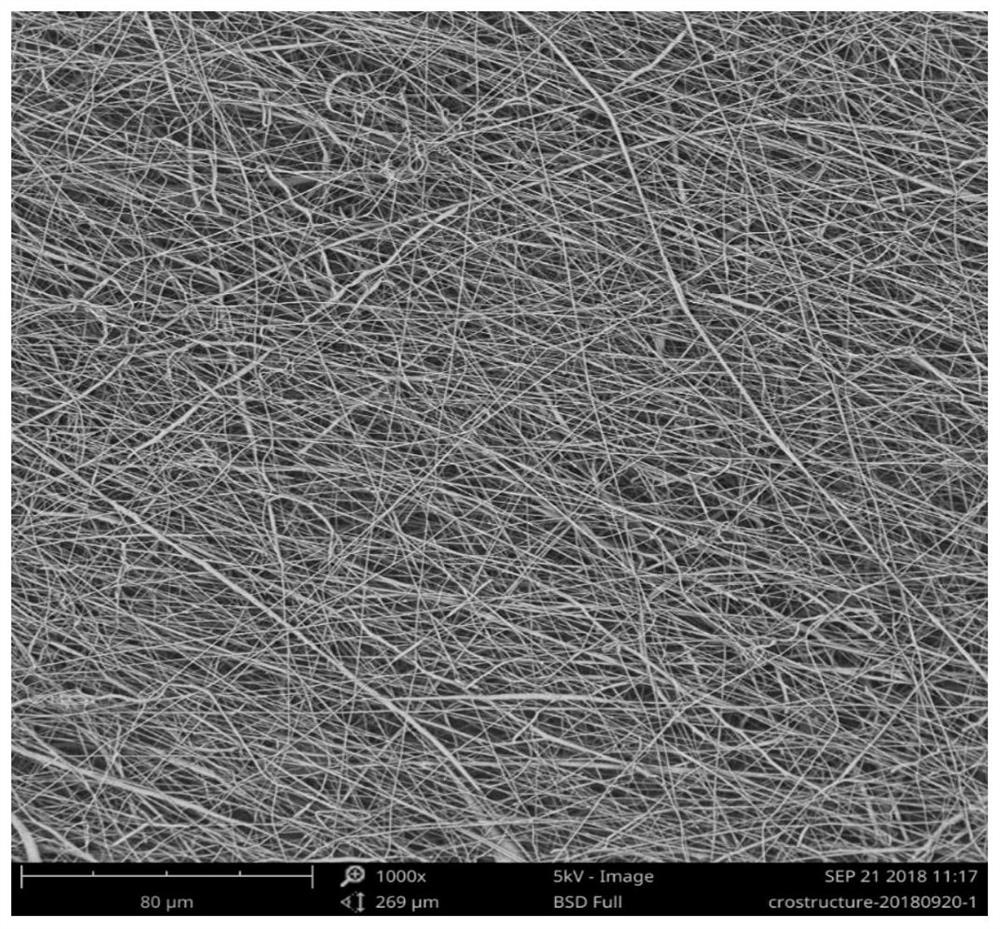

Image

Examples

Embodiment 1

[0059] A material with adjustable surface hydrophilicity / hydrophobicity, the preparation method of which comprises the steps of:

[0060] S1: Synthesis of α-CD-C 12 and γ-CD-C 12

[0061] (1) Co-dissolve 24 equivalents of triphenylphosphine and 24 equivalents of bromine in DMF, then add 1.3 equivalents of α-CD or γ-CD, and react at 80°C for 15 hours;

[0062] (2) Remove half of the solvent, and add a methanol solution of sodium methoxide to the system while lowering to room temperature. After keeping at room temperature for 30 minutes, pour the solution into ice water, collect the precipitate and wash to obtain α-CD-Br or γ-CD- Br;

[0063] (3) 3 equivalents of 1-mercapto n-dodecane of Br on α-CD-Br or γ-CD-Br and 1 equivalent of 1-mercapto n-dodecane of NaOH were dissolved in DMF, at room temperature After standing for 1 hour, add α-CD-Br or γ-CD-Br and store at 80°C for 3 days; then cool the system down to room temperature and add it to water, collect the precipitate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com