Positive photoresist composition and preparation method and application thereof

A technology of positive photoresist and composition, which is applied in the direction of optomechanical equipment, photosensitive materials for optomechanical equipment, optics, etc., and can solve the problems of limiting the application range of photoresist, reducing production efficiency, and a large amount of light energy , achieve excellent physical and chemical properties, improve production efficiency, and have strong photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] According to a second aspect of the present invention, a kind of preparation method of above-mentioned positive photoresist composition is provided, comprises the steps:

[0056] Each component is dissolved by a solvent to obtain a positive photoresist composition.

[0057] In a preferred embodiment, the present invention further includes filtration after dissolution.

[0058] The present invention uses a solvent to dissolve each component, and then filters to obtain a positive photoresist composition; wherein, filtering includes but is not limited to filtering with a filter membrane, and the pore size of the filter membrane is 0.01-1 micron, which is typical but not limited The pore size is, for example, 0.01 micron, 0.02 micron, 0.05 micron, 0.1 micron, 0.2 micron, 0.5 micron, 1 micron.

[0059] The preparation method of the positive photoresist composition provided by the invention has simple process and high excellent rate.

[0060] According to a third aspect of ...

Embodiment 1

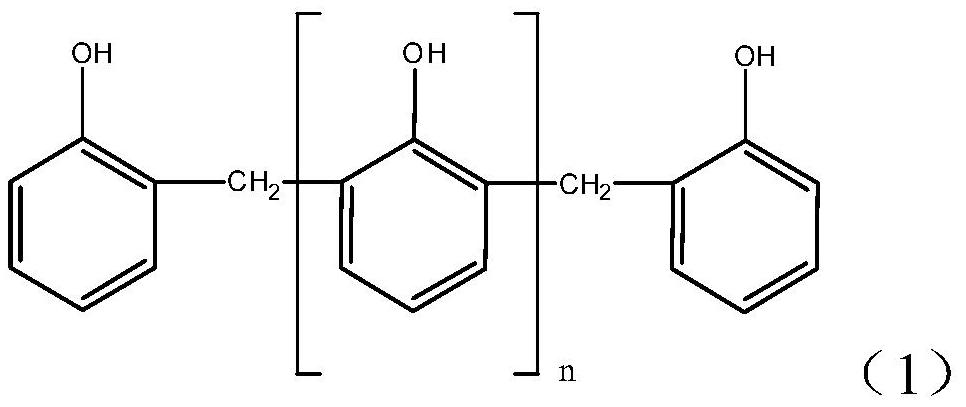

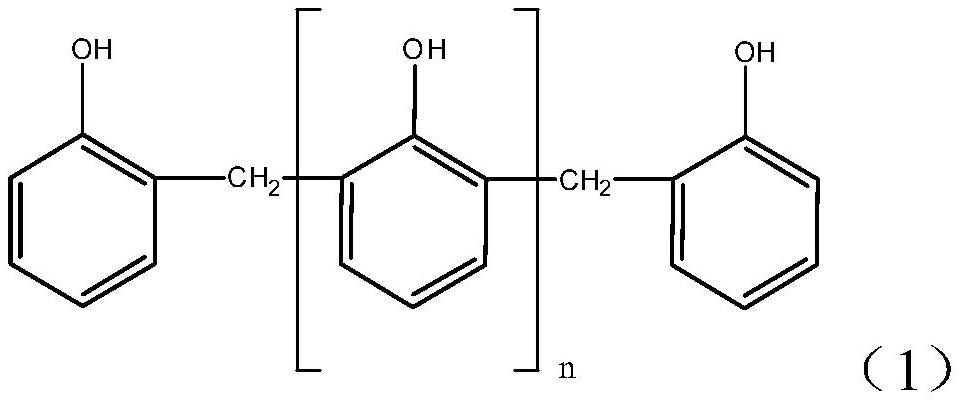

[0064] The weight ratio of the components of the positive photoresist composition of this embodiment is as follows: After mixing the components, they are fully dissolved with the solvent propylene glycol methyl ether acetate, and then filtered through a filter membrane with a pore size of 0.2 microns to obtain a positive photoresist composition. Photoresist composition, wherein, the structure of the phenolic resin of the present embodiment is: Mw is 3000.

[0065]

[0066]

Embodiment 2

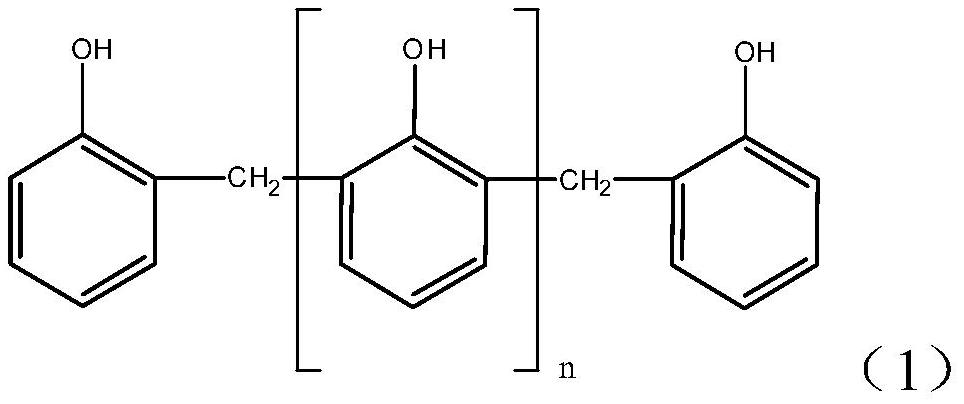

[0068] The weight ratio of the components of the positive photoresist composition of this embodiment is as follows: After mixing the components, they are fully dissolved with the solvent propylene glycol methyl ether acetate, and then filtered through a filter membrane with a pore size of 0.2 microns to obtain a positive photoresist composition. Photoresist composition, wherein, the structure of the phenolic resin of the present embodiment is: Mw is 3000.

[0069] Phenolic Resin 50g Benzomelamine 5g Ethylsulfonic acid 0.5g Acetophenone O-benzoyl oxime 1g Propylene glycol methyl ether acetate 100g

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com