Simulation method for predicting solidification process of vacuum consumable melting cast ingot

A technology for vacuum consumable smelting and simulation methods, which is applied in design optimization/simulation, special data processing applications, complex mathematical operations, etc. Research on consumable arc smelting system, no research on the influence of electromagnetic field on macrosegregation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0106] A simulation method for predicting macro-segregation of vacuum self-consumption smelting ingots, comprising the following steps:

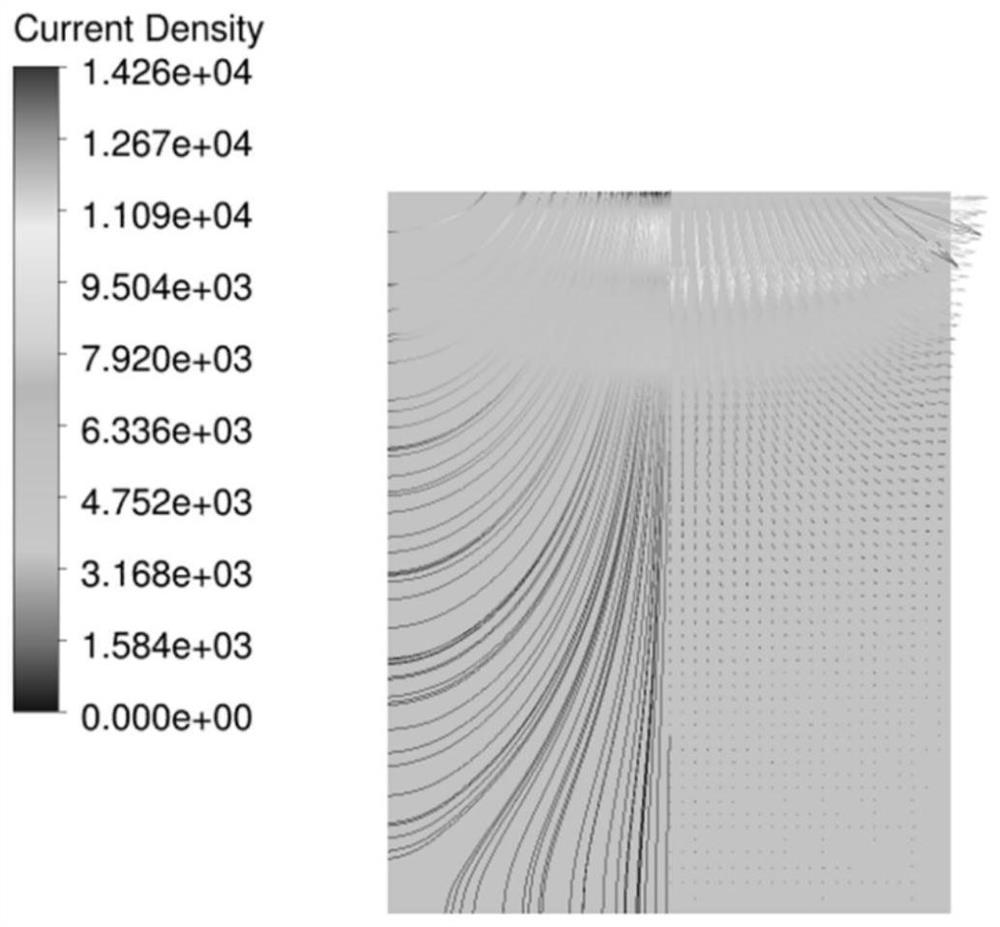

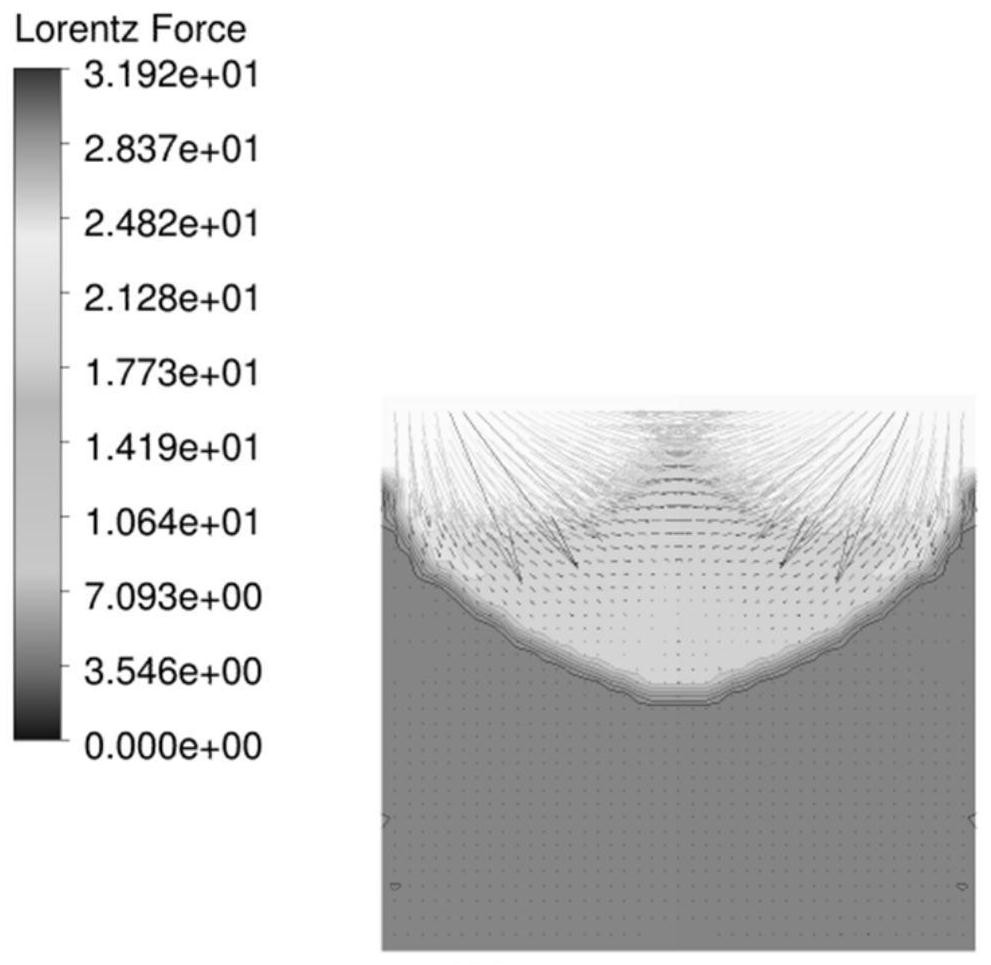

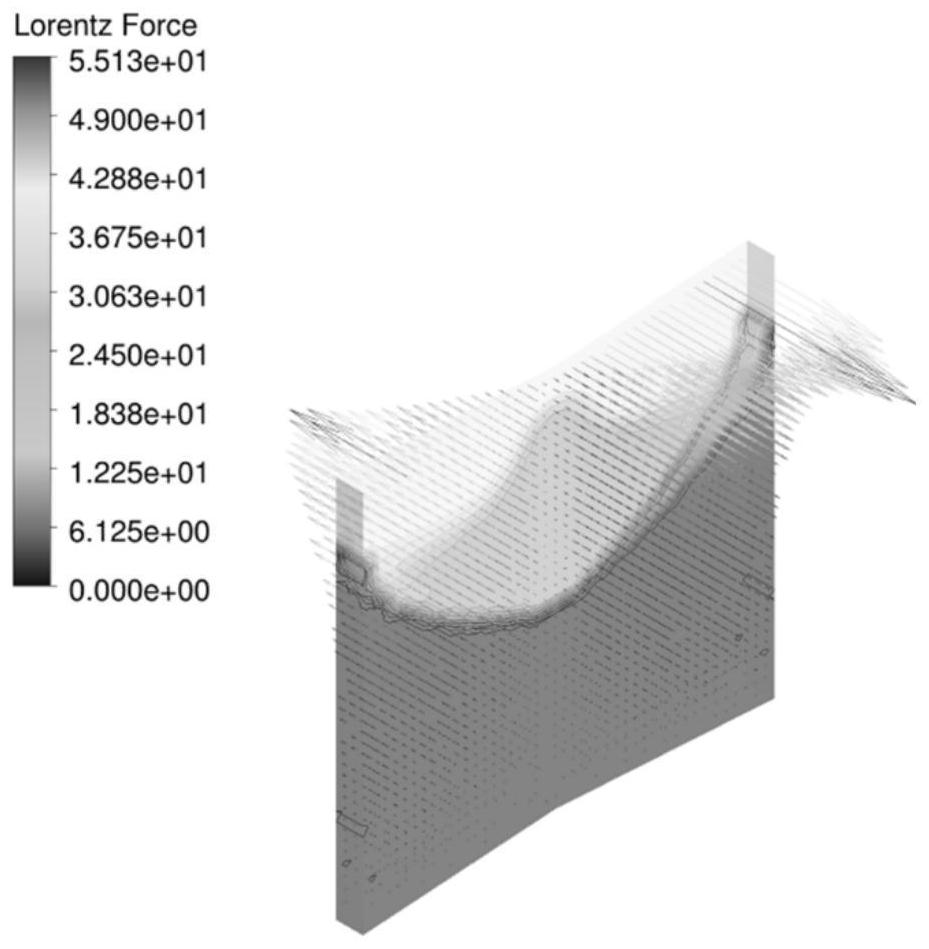

[0107] Step 1. Establish the relevant mathematical model of the electromagnetic field and the flow field, taking into account the electromagnetic field, hot melt convection, the settlement of equiaxed dendrites, and the CET transition from columnar crystals to equiaxed dendrites.

[0108] Step 2: Mesh the geometric model with an appropriate mesh size.

[0109] Step 3, using the Eulerian-Eulerian method to set three phases: molten metal, equiaxed dendrites, and columnar crystals.

[0110] Step 4. Obtain relevant material properties through experiments.

[0111] Step 5. Set relevant boundary conditions, including electric field, magnetic field, and flow field boundary conditions.

[0112] Step 6: Obtain the upward movement speed of the molten pool surface through the relationship between the current and the molten metal formation rate, and set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com