Graphene surface acoustic wave filter device and preparation method thereof

A technology of surface acoustic wave filtering and graphene, which is applied in the fields of sensing and communication, can solve the problems of low bonding force of graphene/piezoelectric substrate interface, rough surface of substrate, affecting device performance, etc., so as to avoid graphene wrinkles, The effect of increasing the quality factor Q value and increasing the filter frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

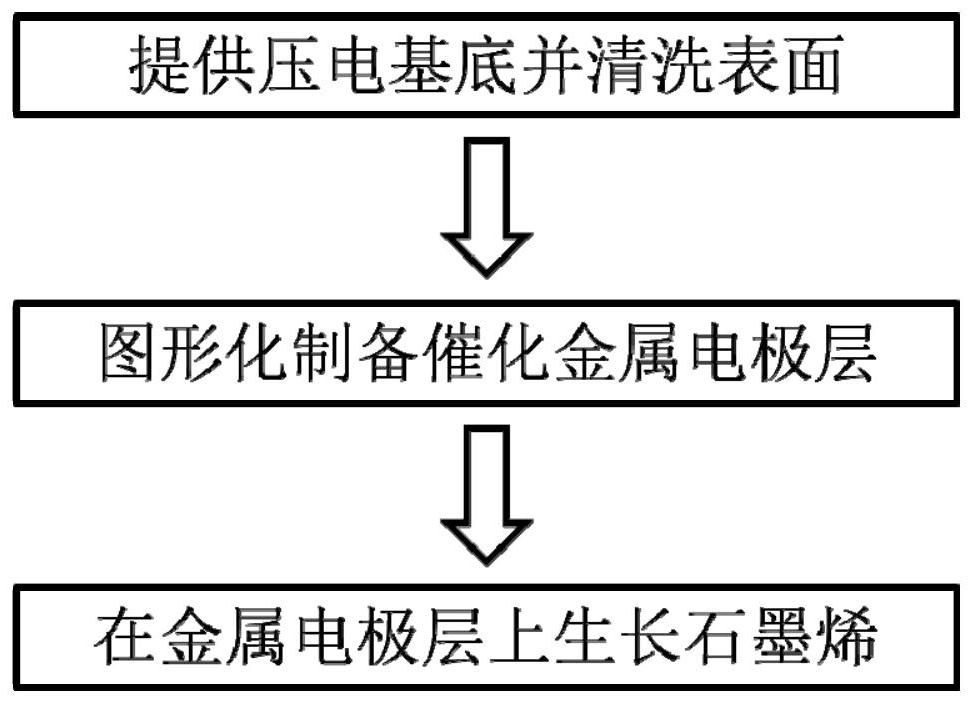

Method used

Image

Examples

Embodiment 1

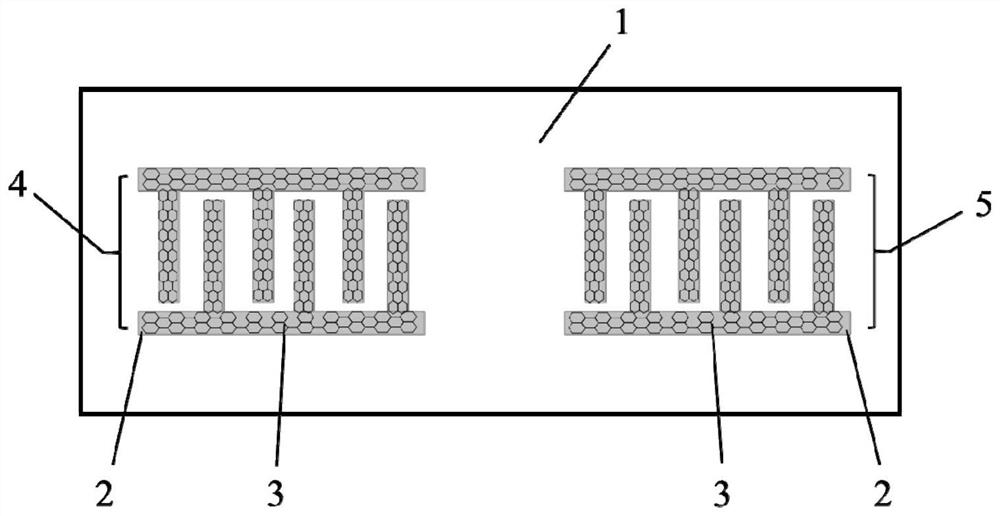

[0031] A graphene surface acoustic wave filter device of the present invention, such as figure 1 As shown, it includes a piezoelectric substrate 1, a catalytic metal electrode layer 2, and a graphene layer 3 arranged in sequence from bottom to top. The graphene layer 3 covers the catalytic metal electrode layer 2, both of which are interdigitated structures. The graphene layer 3 and the catalytic metal electrode layer 2 together form a graphene interdigitated electrode, figure 1 The interdigitated electrodes on the left and right sides of the center are called the surface acoustic wave generator 4 and the surface acoustic wave receiver 5 respectively.

[0032] In this embodiment, the catalytic metal electrode layer 2 is prepared from a transition metal having the function of catalytically cracking a carbon source. The transition metal is specifically nickel, and the thickness of the catalytic metal electrode layer 2 is 10 nm.

[0033] In this embodiment, the piezoelectric sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com