Environment-friendly regenerated brick preparation system

A preparation system and recycled brick technology, which is applied in clay preparation equipment, manufacturing tools, pretreatment control, etc., can solve the problems of difficulty in meeting the needs of building load-bearing walls, poor bearing capacity of recycled bricks, poor bearing capacity, etc., to reduce molding Defects, improving bearing capacity, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

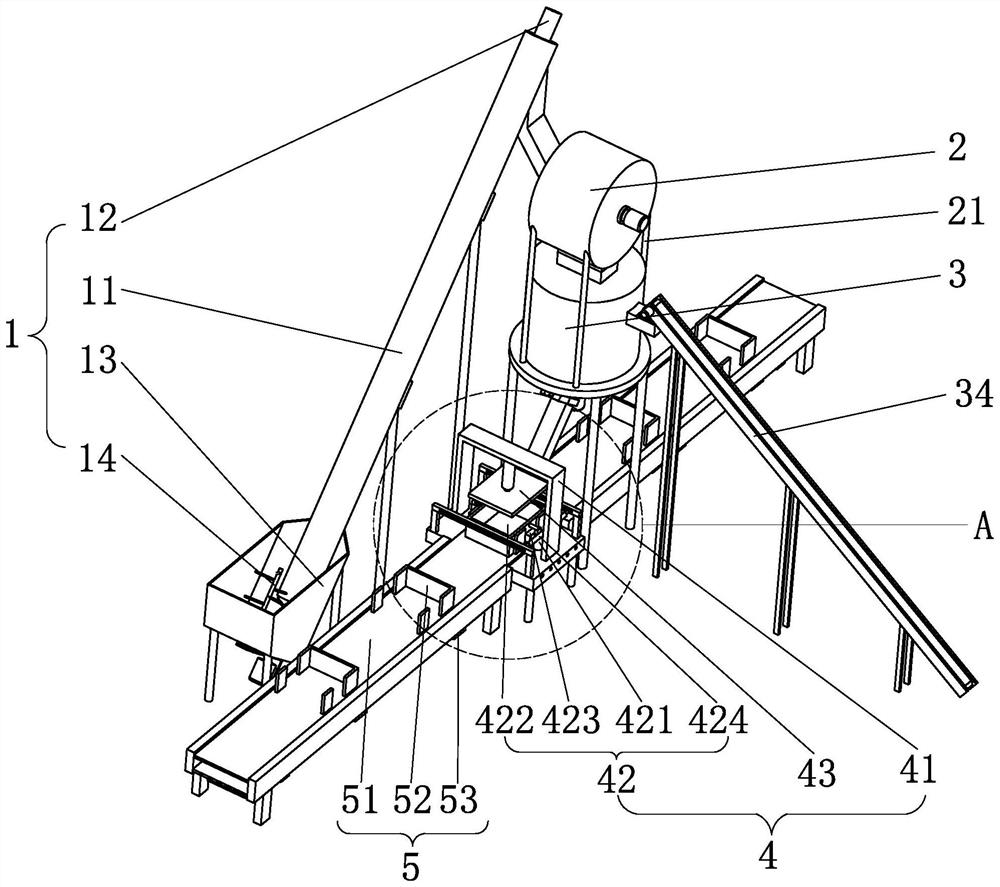

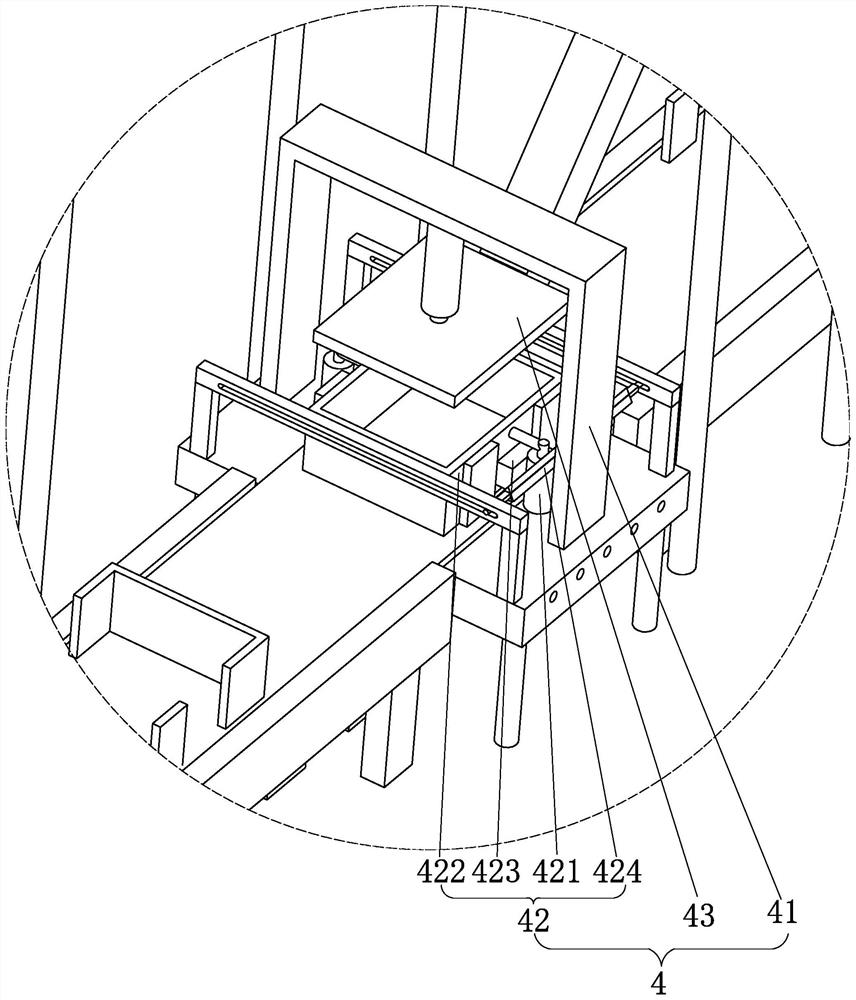

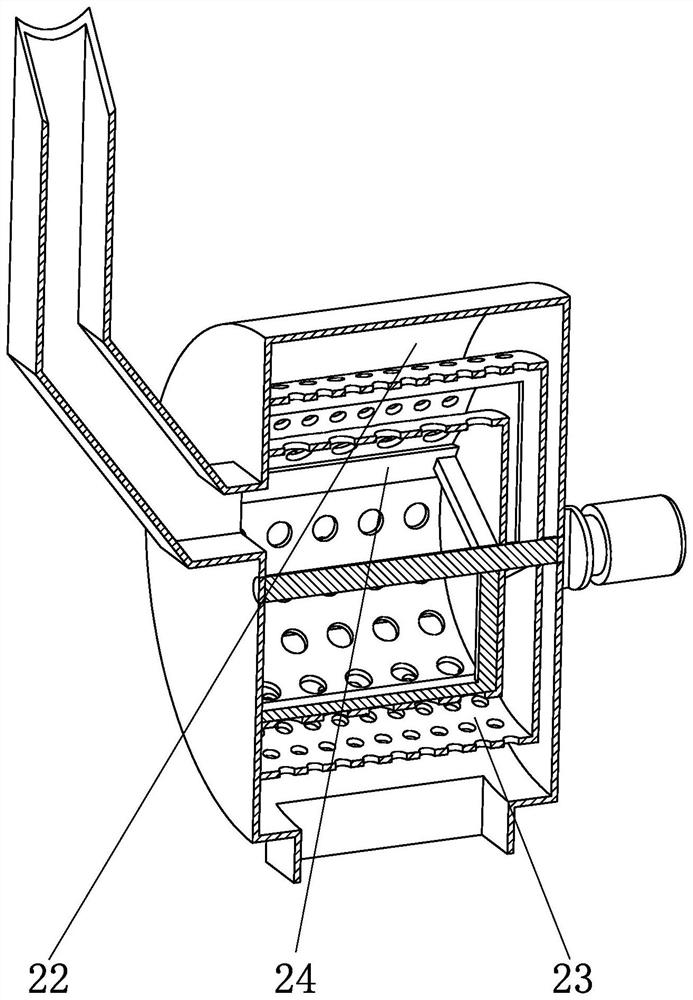

[0036] The following is attached Figure 1-4The application is described in further detail.

[0037] The waste of resources and environmental problems caused by the accumulation of construction waste are becoming more and more obvious. At present, there is a process on the market to prepare environmentally friendly recycled bricks by adding cement materials to construction waste and molding them. However, due to the poor particle size uniformity of construction waste, its combination with cement is not strong enough, and voids and holes are prone to appear during the pressing process. usage requirements. In order to improve the product quality and carrying capacity of environmentally friendly recycled bricks, an embodiment of the present application proposes a preparation system for environmentally friendly recycled bricks.

[0038] The embodiment of the present application discloses an environment-friendly regenerated brick preparation system. refer to figure 1 , The env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com