Preparation method and system of bionic high-purity hypochlorous acid disinfectant fluid

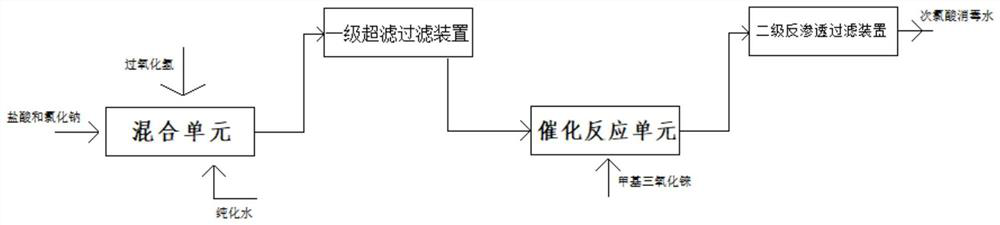

A preparation system and hypochlorous acid technology are applied in the field of preparation of biomimetic high-purity hypochlorous acid disinfection water, and can solve the problems of impure product, low electrolysis yield of slightly acidic hypochlorous acid water, and high electrolysis cost, and achieve Low cost and beneficial to large-scale utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a kind of preparation method of bionic high-purity hypochlorous acid disinfection water, the configuration amount m of the immobilized methyl rhenium trioxide catalyst is 800 mg, the mass concentration of hydrogen peroxide is 3%, and the concentration of sodium chloride is 3%. The mass concentration is 6%, and the mass concentration of hydrochloric acid is 0.3%. The mixing ratio of purified water: hydrogen peroxide: sodium chloride: hydrochloric acid is 500:0.5:1:0.1. The catalytic reaction was carried out at room temperature. After the reaction, the content of hypochlorous acid was measured by DPD spectrophotometry, and the content of hypochlorous acid reached 379.5mg / L; the pH value was measured with a portable pH meter, and the pH value was 6.17; Portable chloride ion detector was used to test, and the residual amount was 213mg / L; chlorate was tested by ion chromatography, and the generated amount was ≤0.01mg / L; the conversion efficiency of c...

Embodiment 2

[0034] This embodiment provides a kind of preparation method of biomimetic high-purity hypochlorous acid disinfection water, the configuration amount m of the immobilized methyl rhenium trioxide catalyst is 1000mg, the mass concentration that adopts hydrogen peroxide is 3.5%, adopts sodium chloride The mass concentration is 5.5%, and the mass concentration of hydrochloric acid is 0.5%. The mixing ratio of purified water: hydrogen peroxide: sodium chloride: hydrochloric acid is 3000:0.5:1:0.15. The catalytic reaction was carried out at room temperature. After the reaction, the content of hypochlorous acid was measured by DPD spectrophotometry, and the content of hypochlorous acid reached 385.1mg / L; the pH value was measured with a portable pH meter, and the pH value was 5.64; The residual amount was 204mg / L when tested by a portable chlorine ion analyzer; the chlorate was tested by an ion chromatograph, and the generated amount was ≤0.01mg / L; the conversion efficiency of chlori...

Embodiment 3

[0036] This embodiment provides a kind of preparation method of biomimetic high-purity hypochlorous acid disinfection water, the configuration amount m of the immobilized methyl rhenium trioxide catalyst is 800mg, the mass concentration of adopting hydrogen peroxide is 2.5%, adopting the concentration of sodium chloride The mass concentration is 5.8%, and the mass concentration of hydrochloric acid is 0.4%. The mixing ratio of purified water: hydrogen peroxide: sodium chloride: hydrochloric acid is 200:0.5:1:0.15. The catalytic reaction was carried out at room temperature. After the reaction, the content of hypochlorous acid was measured by DPD spectrophotometry, and the content of hypochlorous acid reached 179.7mg / L; the pH value was measured with a portable pH meter, and the pH value was 5.49; The residual amount was 108mg / L when tested by a portable chloride ion detector; the chlorate was tested by an ion chromatograph, and the generated amount was ≤0.01mg / L; the conversion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com