Waterborne epoxy self-leveling mortar and preparation method thereof

A technology of self-leveling mortar and water-based epoxy, which is applied in the field of building materials, can solve the problems of low fire protection level, easy cracking, and difficult to meet, and achieve the effect of high cost performance, good effect, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

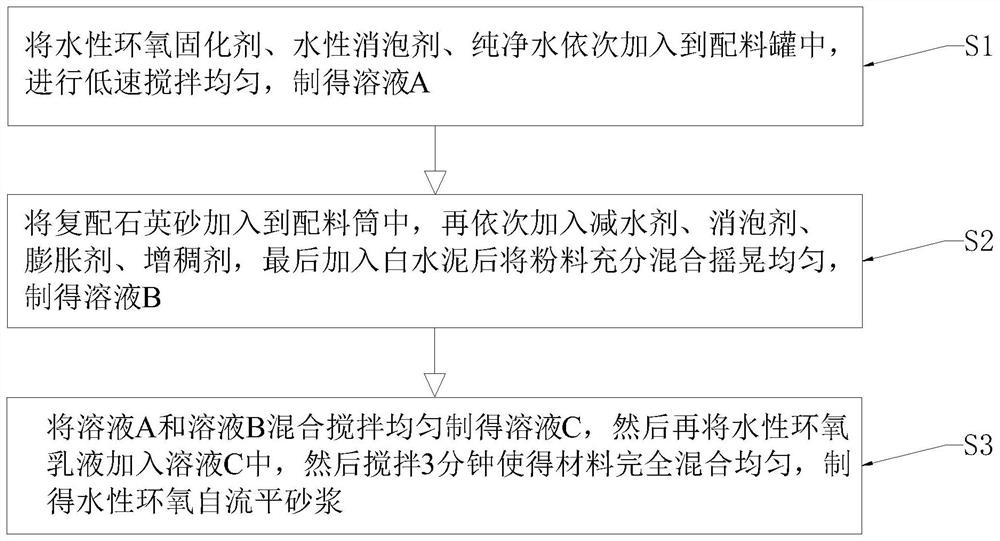

[0051] A kind of preparation method of water-based epoxy self-leveling mortar, the preparation method of this water-based epoxy self-leveling mortar comprises the following steps:

[0052] Add 3.95kg of Evonik Anquamine 287, 0.05kg of BYK-024 defoamer, and 8kg of purified water into the batching tank in sequence, and stir evenly at a low speed to prepare solution A;

[0053] Take 50kg of 40-80 mesh, 80-120 mesh, and 120-200 mesh machine-made snowflake white compound quartz sand, add 0.2kg of Zhaojia 8020, 0.1kg of German Mingling Agitan P803, 0.4kg of aluminum hydroxide and fiber Add 0.02kg of plain ether, and finally add 30.28kg of Aalbo 52.5 white cement, mix the powder evenly, and prepare solution B;

[0054] Mix solution A and solution B evenly to prepare solution C, then add 5kg of Evonik Ancarez AR468 to solution C, and then stir for 3 minutes to make the materials completely mixed uniformly to prepare water-based epoxy self-leveling mortar.

Embodiment 2

[0056] A kind of preparation method of water-based epoxy self-leveling mortar, the preparation method of this water-based epoxy self-leveling mortar comprises the following steps:

[0057] Add 3.95kg of Evonik Anquamine 287, 0.05kg of BYK-024 defoamer, and 8kg of purified water into the batching tank in sequence, and stir evenly at a low speed to prepare solution A;

[0058] Take 50kg of 40-80 mesh, 80-120 mesh, and 120-200 mesh machine-made snowflake white compound quartz sand, add 0.2kg of Zhaojia 8020, 0.1kg of German Mingling Agitan P803, 0.6kg of aluminum hydroxide and fiber 0.01kg of plain ether, and finally add 29.09kg of Aalbo 52.5 white cement, mix the powder evenly, and make solution B;

[0059] Mix and stir solution A and solution B evenly to prepare solution C, then add Evonik PRO-8622 5kg into solution C, and then stir for 3 minutes to make the materials completely mixed uniformly to prepare water-based epoxy self-leveling mortar.

Embodiment 3

[0061] A kind of preparation method of water-based epoxy self-leveling mortar, the preparation method of this water-based epoxy self-leveling mortar comprises the following steps:

[0062] Add 3.95kg of Zhuohui WP-87, 0.05kg of Tego-901W defoamer, and 8kg of purified water into the batching tank in turn, and stir evenly at a low speed to prepare solution A;

[0063] Take 50kg of 40-80 mesh, 80-120 mesh, and 120-200 mesh machine-made snowflake white compound quartz sand, add 0.2kg of Zhaojia 8020, 0.1kg of German Mingling Agitan P803, 0.4kg of aluminum hydroxide and fiber Add 0.02kg of plain ether, and finally add 30.28kg of silver fir 52.5 white cement, mix the powder evenly, and prepare solution B;

[0064] Mix and stir solution A and solution B to make solution C, then add 5kg of Zhuohui 61% RLC to solution C, and then stir for 3 minutes to make the materials completely mixed and get water-based epoxy self-leveling mortar.

[0065] To sum up, with the help of the above tech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com