Preparation method of semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device preparation, can solve problems such as increased junction leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

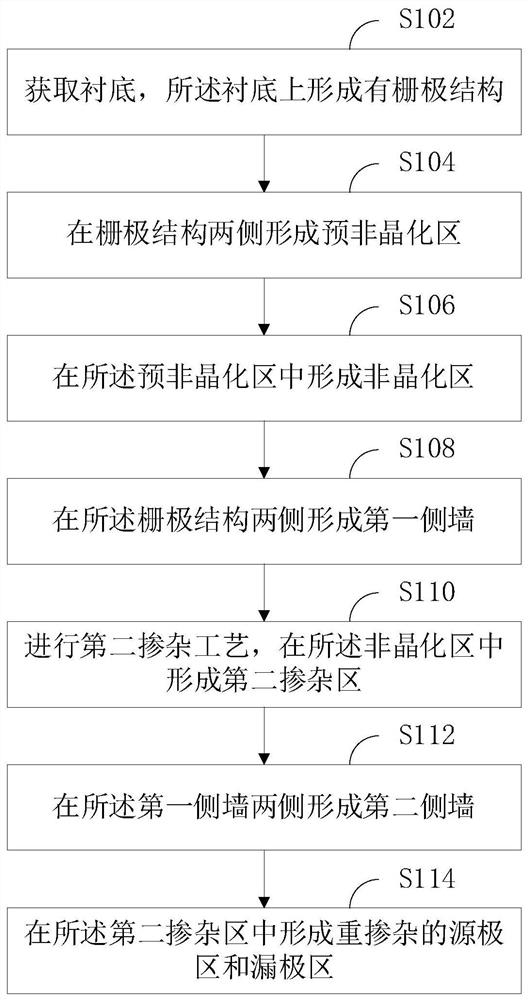

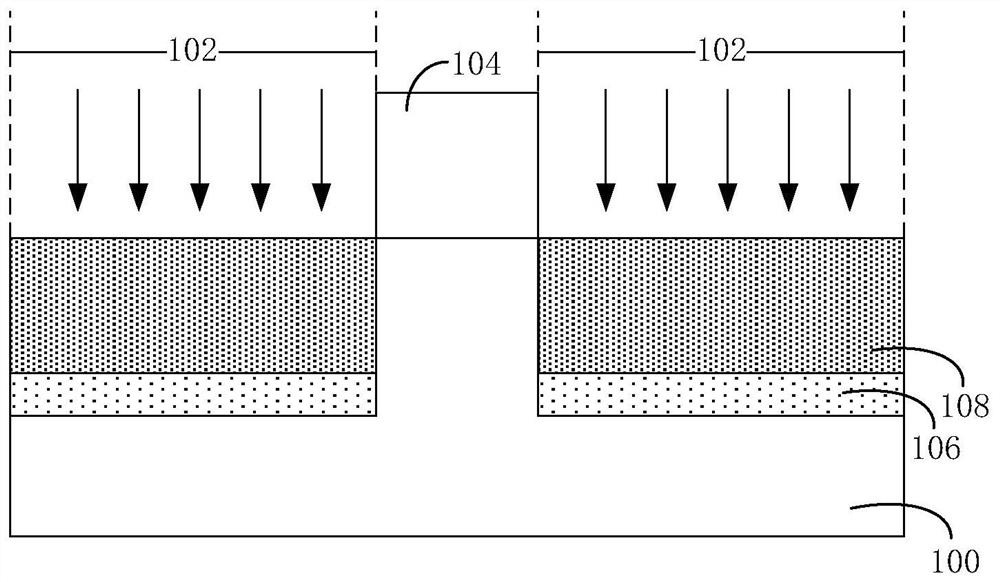

[0058] Such as figure 1 As shown, in one of the embodiments, a method for preparing a semiconductor device is provided, including:

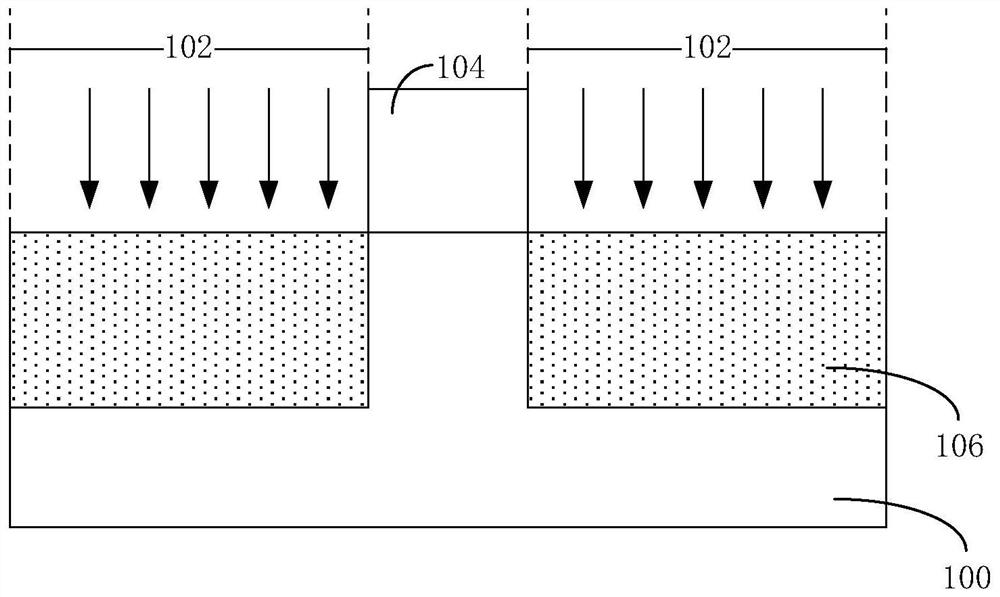

[0059] S102, acquiring a substrate, on which a gate structure is formed.

[0060] The substrate may be a silicon substrate, a silicon-on-insulator substrate (SOI), a stacked silicon-on-insulator substrate (SSOI), a stacked silicon-germanium-on-insulator substrate (S-SiGeOI), or a silicon-germanium-on-insulator substrate (SiGeOI) and germanium-on-insulator substrate (GeOI) and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com